"∽" shaped carbon-free car

A carbon-free car and car technology, which is applied to toy cars, toys, remote control toys, etc., can solve the problems of no carbon, low cost, unstable center of gravity of the car, and unfavorable starting of the car. The effect of long distance and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

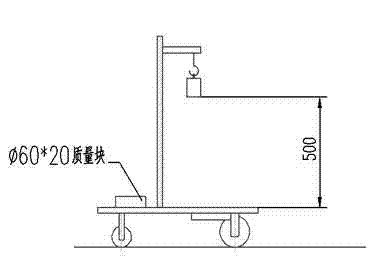

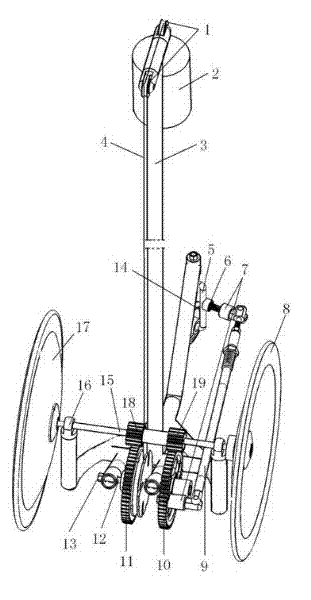

[0022] Such as Figure 1-9 As shown, the driving part and the steering part are installed on the vehicle frame to form a trolley; the vehicle frame is an upside-down type, consisting of an underframe 13, a drive shaft support 16, a front wheel support 6 and a potential energy support 3. The triangular underframe 13 Potential energy support 3 is vertically installed in the center of the triangular underframe 13, and front wheel support 16 is installed respectively on both sides of the rear end of the triangular underframe 13, and front wheel support 6 is installed on the front end of the triangular underframe 13; 1, driving shaft 15, fixed shaft 12, front wheel 14, driving wheel 17, driven wheel 8, wire rope 4, left small gear 18 and left large gear 11 are formed, and front wheel steering shaft 5 is installed on the front wheel support 6, front wheel Front wheel 14 is installed on the wheel steering shaft 5, fixed pulley 1 is installed on the top of potential energy support 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com