A die-cutting machine suitable for roll materials using a combined die-cutting method

A combined die-cutting machine technology, applied in metal processing and other directions, to achieve the effect of reducing manufacturing cost and use cost, reducing labor intensity and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

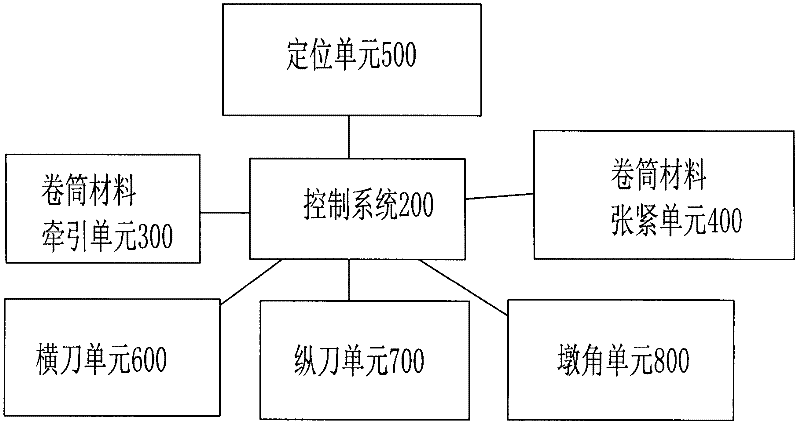

[0030] like figure 1 As shown, a die-cutting machine suitable for roll materials using a combined die-cutting method in the present invention includes a frame 100, a roll material traction unit 300 respectively connected to a control system 200, and a roll material tensioning unit. Unit 400, positioning unit 500, horizontal knife unit 600, vertical knife unit 700 and pier corner unit.

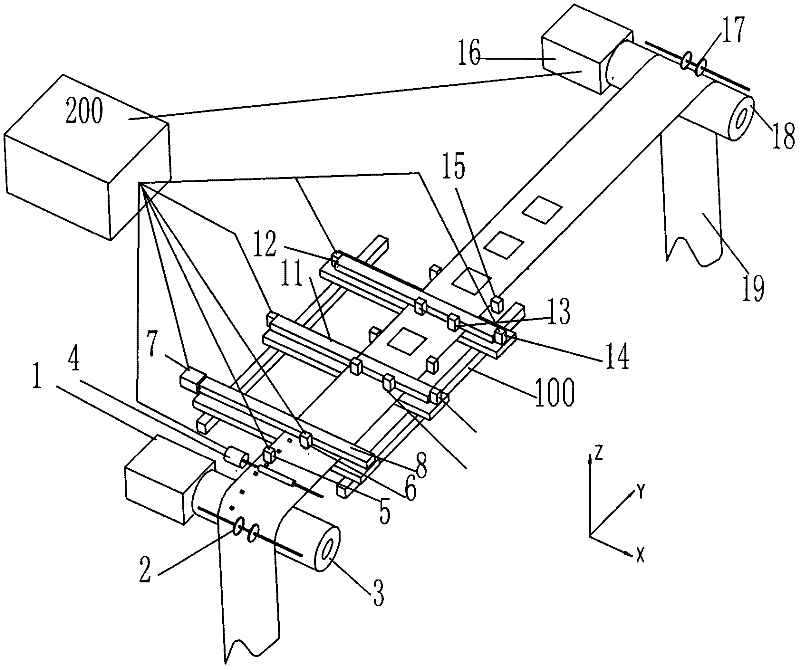

[0031] like figure 2 As shown, the roll material pulling unit 300 controls the positive movement of the roll material 19 along the Y direction (ie, the length direction) of the roll material, and the roll material tensioning unit 400 is used to move the roll material 19 The reversal of the Y direction provides a tension force to prevent the roll material 19 from shaking and sagging. The roll material pulling unit 300 and the roll material tensioni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap