Compression, storage, exchange of truck compartment barrel type garbage transfer station

A technology for garbage transfer stations and carriages, which is applied in the directions of garbage conveying, garbage collection, and storage devices. The effect of shipping cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

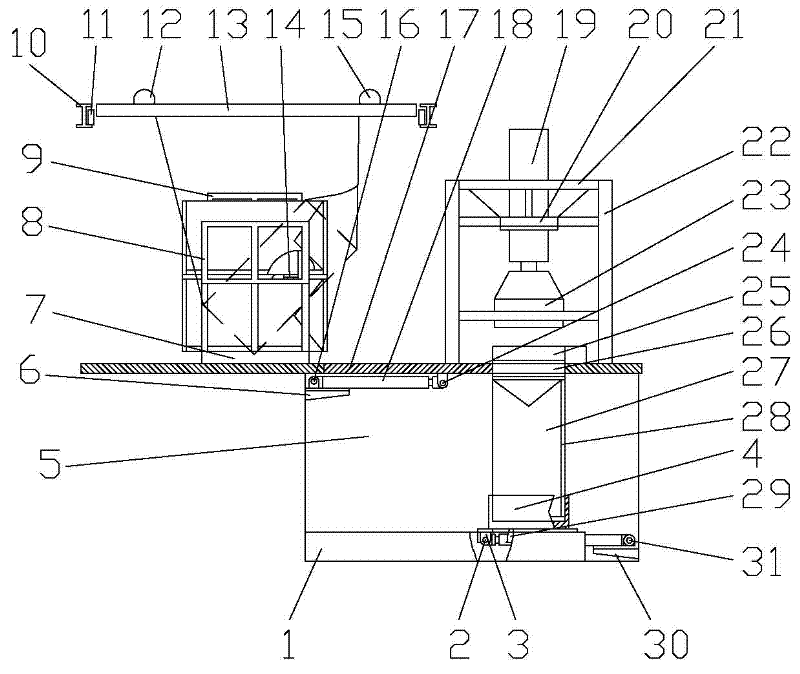

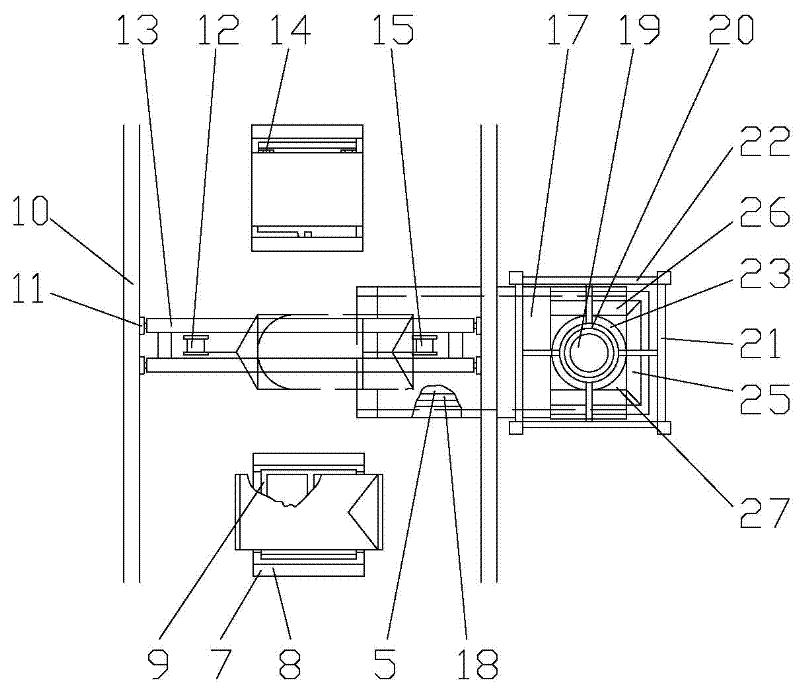

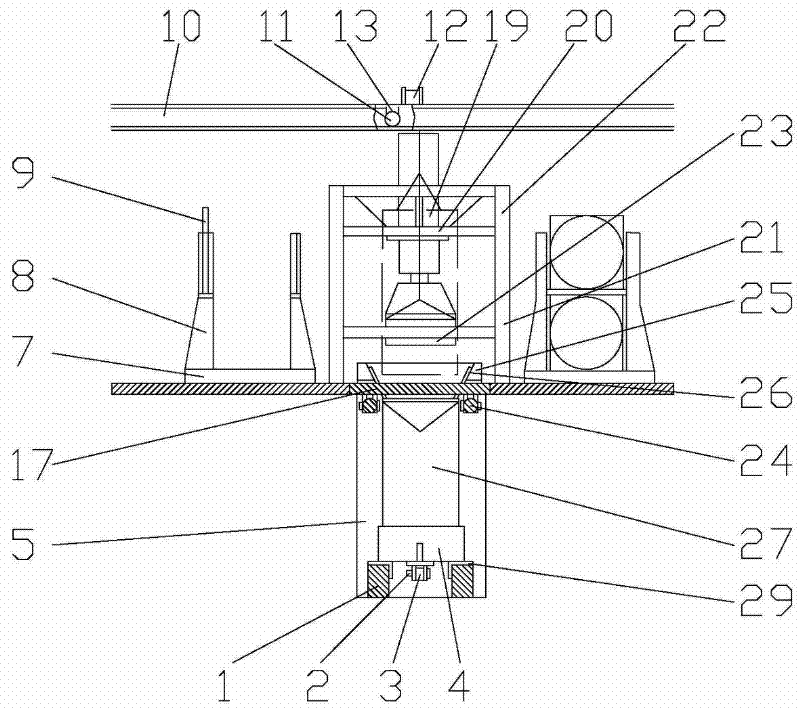

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Such as Figure 1-3 Shown, the present invention comprises garbage compressor 21, double-rope drum lifting beam 13, garbage box tube 27 and box tube storage frame 7, and garbage compressor 21 is made up of first hydraulic cylinder 19, hydraulic cylinder support 22, box tube seat 4 Constituted with the cover plate 17, the garbage box tube 27 is placed in the pit 5, and there is a movable cover plate 17 placed on the mouth of the pit between the lower part of the hydraulic cylinder support 22 of the garbage compressor 21 and the top of the garbage box tube 27, and the hydraulic cylinder The bracket 22 is a frame structure in which four columns are connected to the crossbeam, and the disc-shaped supporting plate 20 integrated with the upper and middle crossbeams is connected to the first hydraulic cylinder 19 through bolts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com