Method for excavating tunnel in high liquid limit soil

A technology of tunnel excavation and high liquid limit soil, applied in the field of improvement of CRD excavation method, can solve problems affecting construction progress, manual excavation, primary lining damage, etc., improve construction safety and facilitate excavation , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

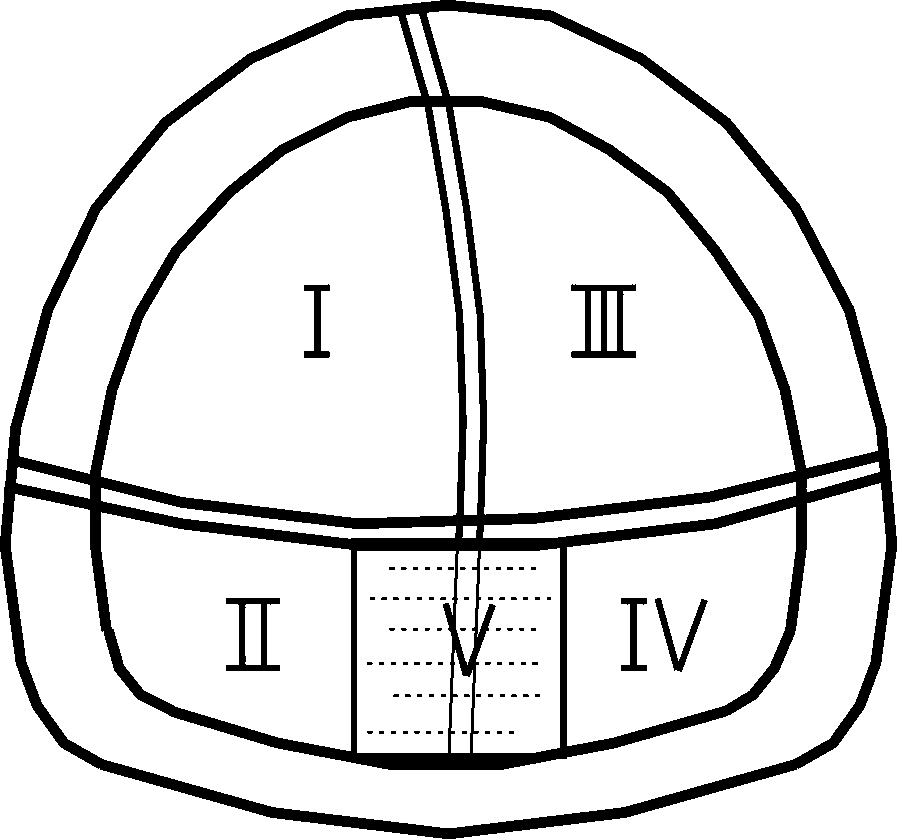

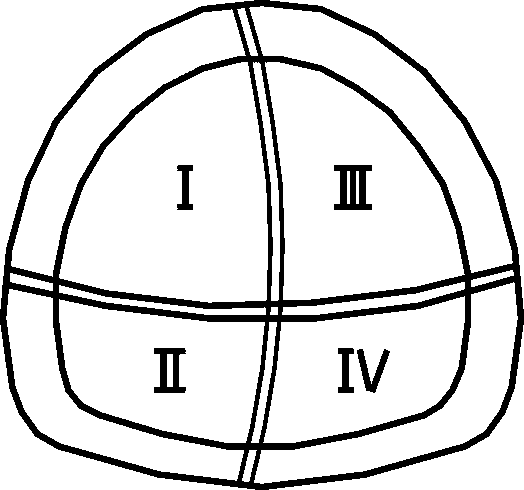

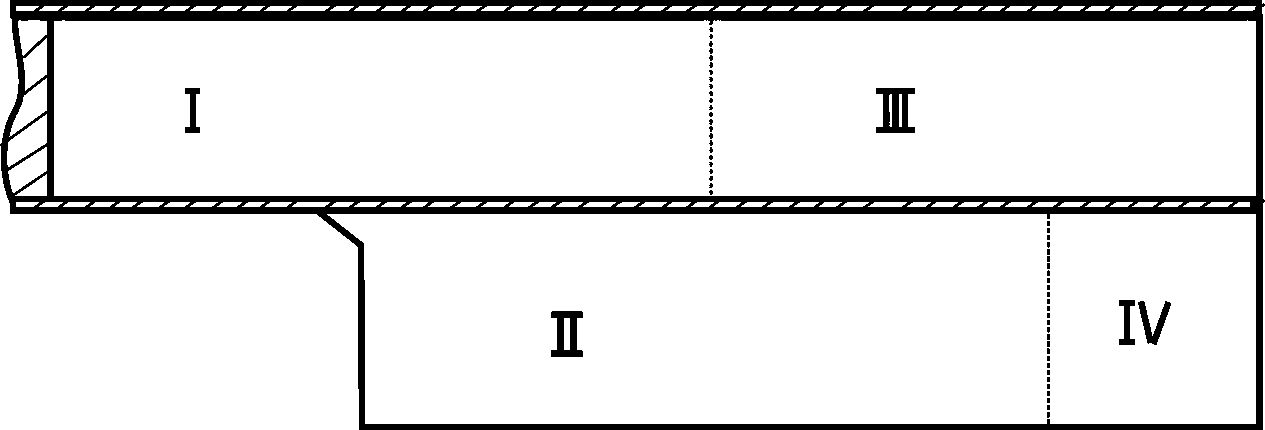

[0020] Such as figure 1 Shown, a kind of tunnel excavation method in high liquid limit soil, comprises the following steps:

[0021] A. The excavator is supplemented by manual excavation of the surrounding rock above the side wall, and the middle partition wall still needs to be installed. When excavating, first excavate the left upper part I, and immediately carry out shotcrete protection for the face of the tunnel and excavation after completion. Fresh surrounding rock, spray anchor support for the middle partition wall;

[0022] B. Install the I-beam on the upper part I on the left side, then install the bolts and grout, and spray steel fiber concrete to complete the initial support of the vault of the I part;

[0023] C. Excavate the upper part III on the right side of the tunnel, using the excavator as the main method combined with manual excavation. After excavating for a certain distance, spray concrete protection on the face of the tunnel and the surrounding rock of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com