Reverse tunnel entering construction method for tunnel special-shaped protection arch on slope accumulation body

A construction method and tunnel technology, which is applied in tunnels, tunnel linings, excavations, etc., can solve problems such as cave entrances that are prone to collapse, and achieve the effects of reducing the amount of single excavation, ensuring construction safety, and reducing construction disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

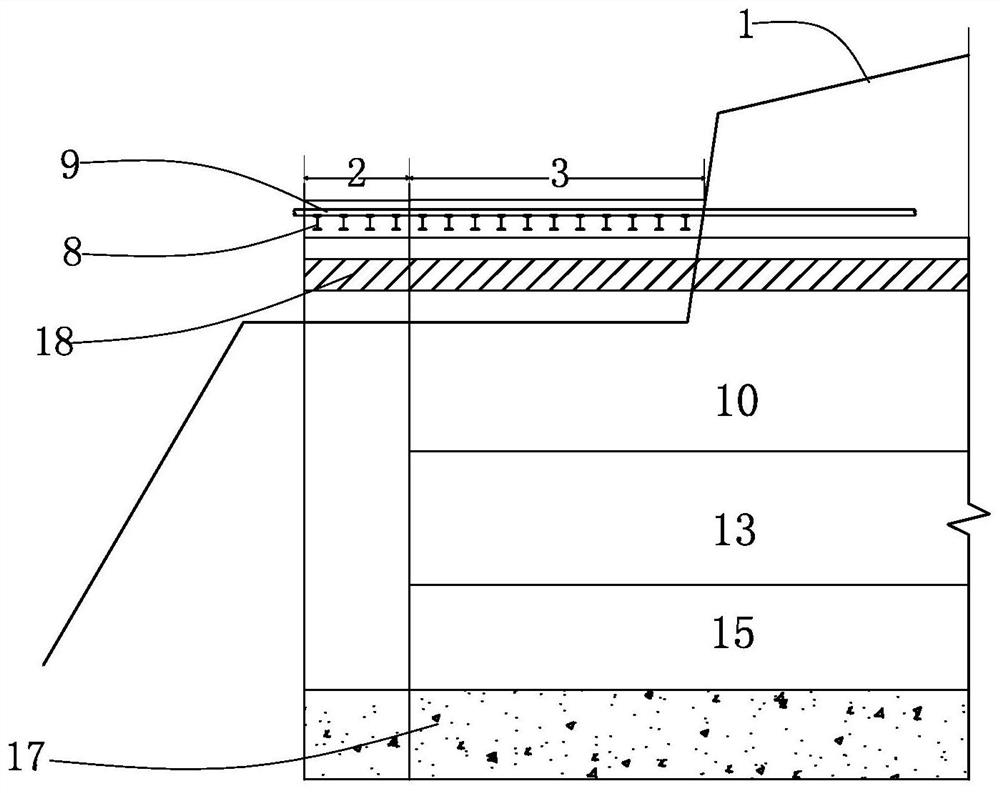

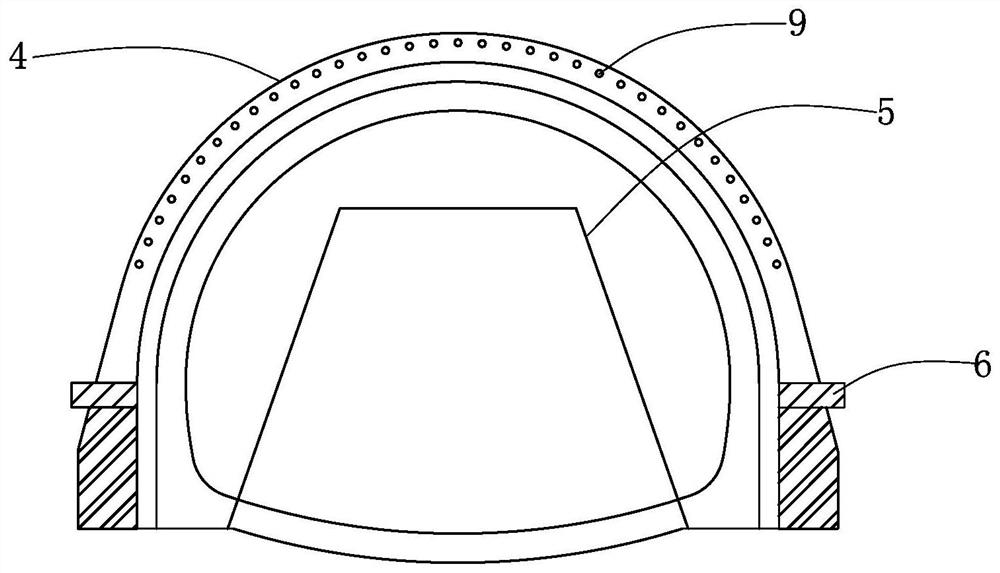

[0023] The implementation of the present invention will be described below through specific embodiments in conjunction with the accompanying drawings.

[0024] In a specific embodiment of the present invention, the surrounding rock of the tunnel is fully-moderately weathered Mesoproterozoic sericite albite quartz schist, and the entrance section is a shallow buried tunnel. At the foot of the slope, the natural slope angle is about 28°. Before the tunnel construction, it was in a stable state. After the excavation of the foot of the slope, it is easy to lose stability, which has a certain impact on the stability of the uphill slope at the entrance of the tunnel.

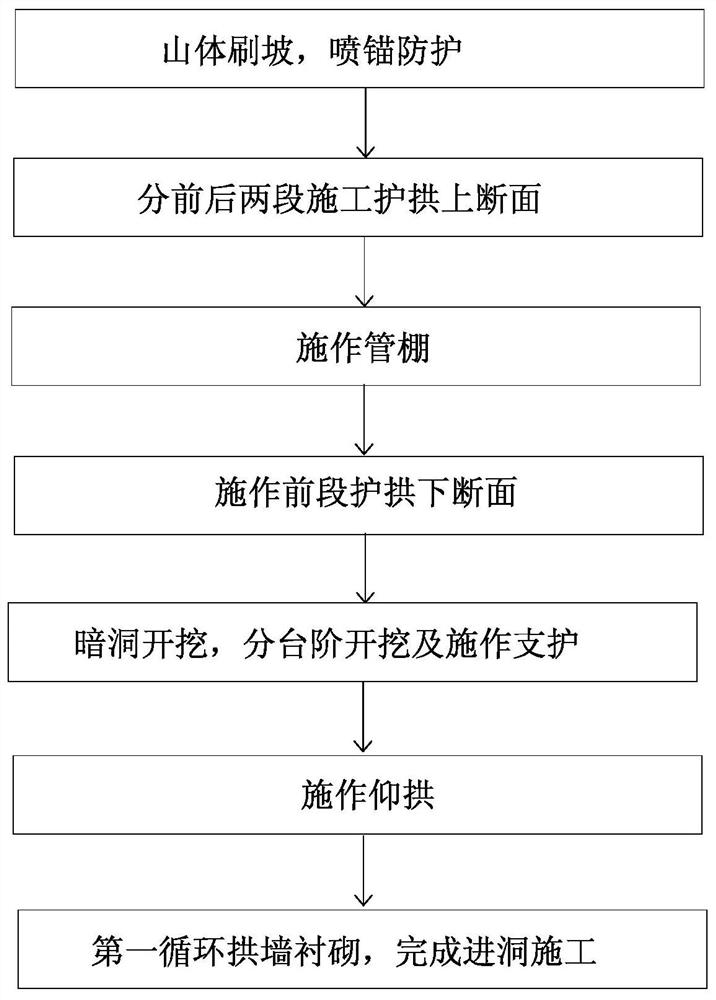

[0025] In order to ensure safe entry into the tunnel during tunnel construction, the present invention is used to construct protective arches and enter into the tunnel. The construction process is as follows: figure 1 As shown, the specific method is as follows:

[0026] (1) Brush the slope around the mountain around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com