A construction method for assembling jacking shield with fluid balance subdivision and shield machine used therefor

A construction method and shield machine technology, which can be applied in vertical shaft equipment, earth drilling, wellbore lining, etc., can solve the problems affecting the safety and normal use of buildings (structures), inability to overcome underground obstacles of steel bars, slow construction speed, etc. problem, to achieve the effect of overcoming short jacking distance, fast construction speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

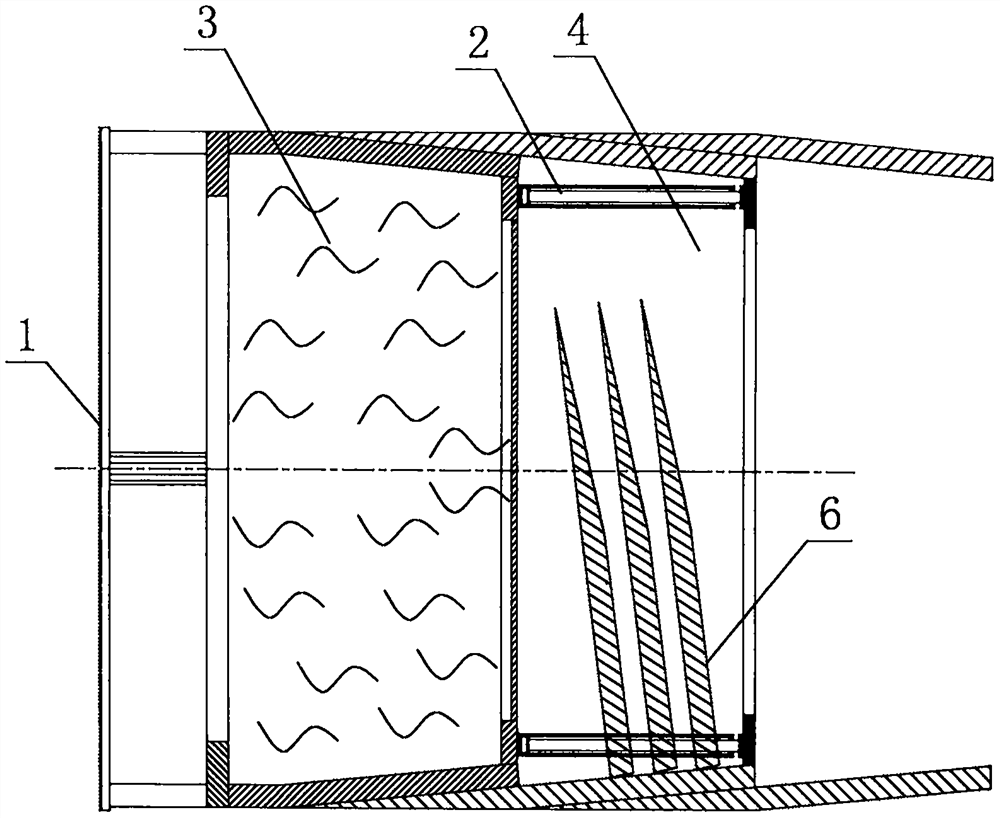

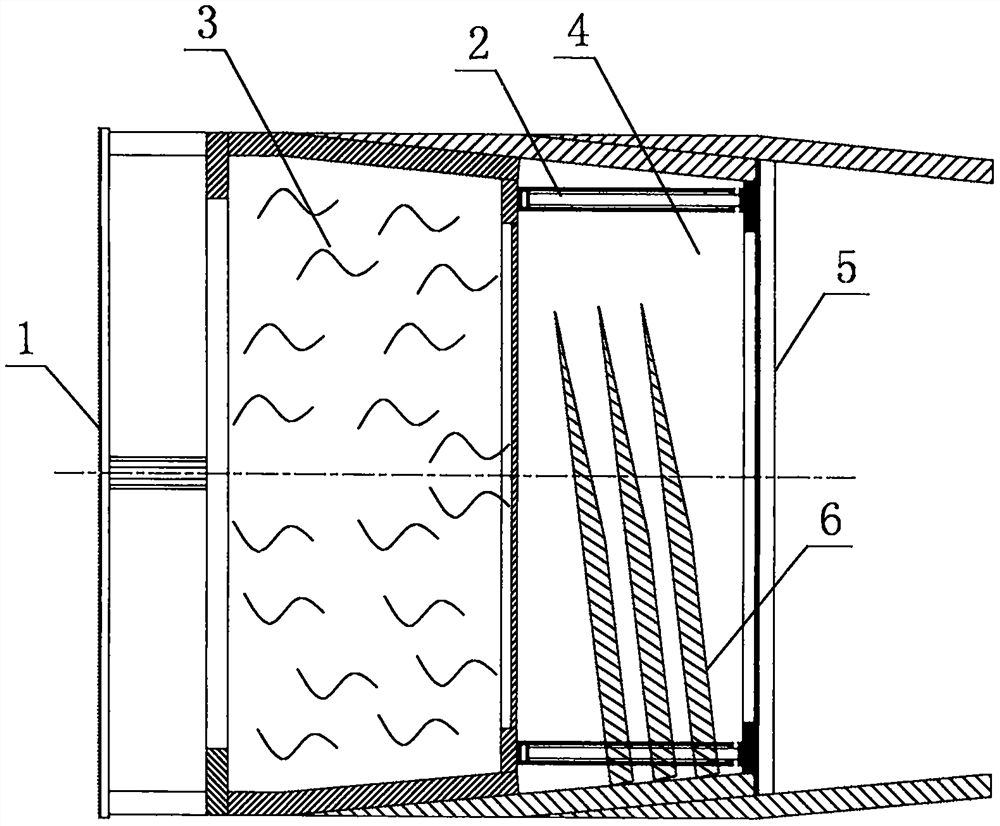

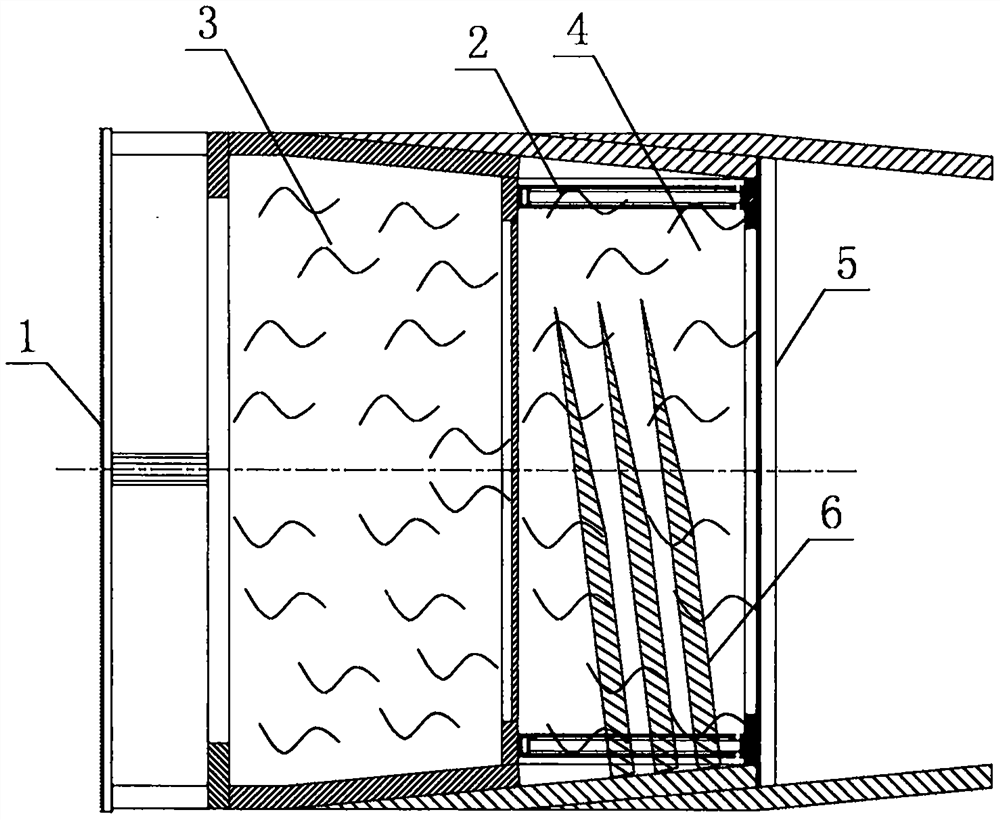

[0018] As an embodiment of the present invention, the following first combines figure 2 The structure and working principle of a fluid balance subdivision assembly jacking shield machine of the present invention are introduced. like figure 2 As shown, the fluid balance subdivision assembly jacking shield machine of the present invention includes a cutting device (1), a jacking device (2), a jacking cabin (3), an assembly cabin (4), a sealing door (5), a fluid Conveying device, underwater installation robot seven parts. The cutting device (1) is an appliance located at the machine head position to cut the rock and soil mass, and the corresponding cutter head of the existing shield machine or pipe jacking machine can be used. The jacking device (2) is a device that provides power for pushing the shield machine forward, and a combination of multiple sets of jacks can be used as the jacking device (2). The jacking cabin (3) is located between the cutting device (1) and the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com