A method for constructing underground garages between residential buildings

A technology for underground garages and residential buildings, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of large construction space, low construction efficiency, and long construction period, and achieve ingenious and reasonable design, increased construction speed, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

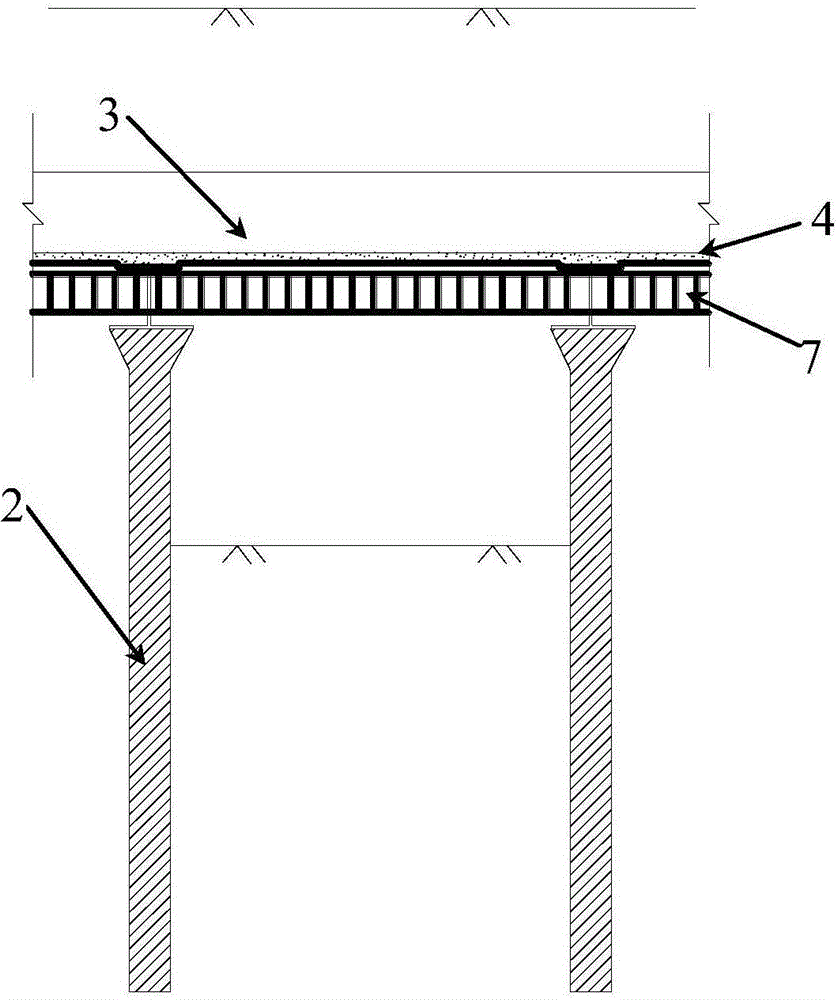

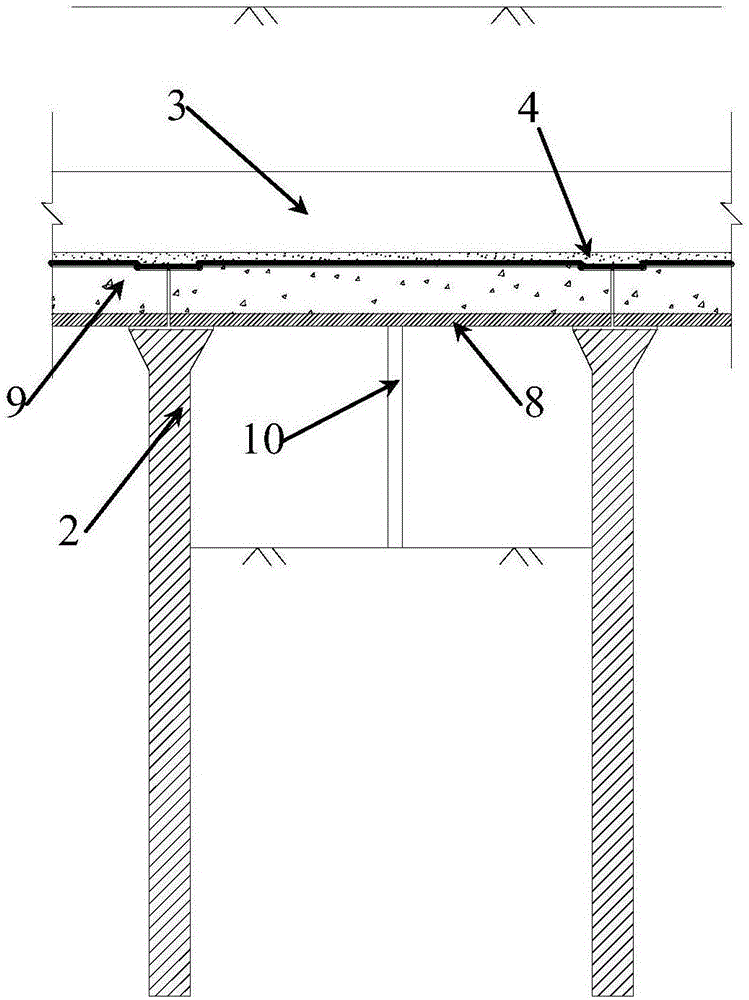

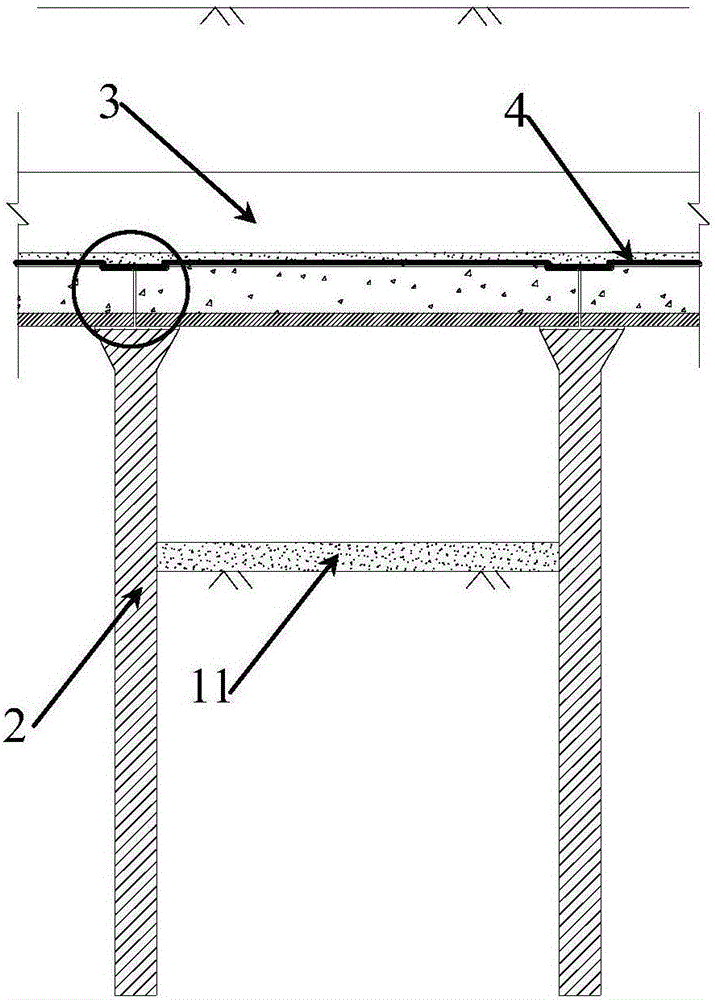

[0046] **The community was built in 2003. The project is a six-story masonry brick-concrete structure with a construction area of 11,217 square meters and a total building length of 143.3 meters. The foundation is notoginseng lime soil, reinforced concrete platform beams. The layout between residential buildings is 5m road + 35m green belt + 5m road. Since there was no underground garage in the early construction period, it is difficult to park vehicles in the community and the roads are congested. Moreover, the community is located in a relatively prosperous area, and there are many social vehicles parked in the community, causing a series of disputes. In order to solve the problem of parking vehicles in the community and reduce social disputes, it is planned to excavate the underground garage under the green belt between buildings by using the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com