Process and equipment for increasing block coal rate

A block rate and equipment technology, applied in the field of improving coal block rate technology and equipment, can solve problems such as loss of block rate, ineffective economic benefits, and drop in lump coal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

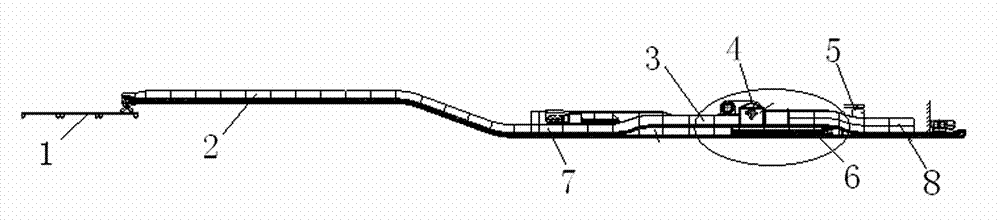

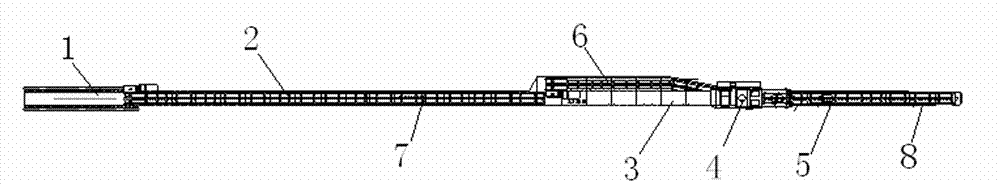

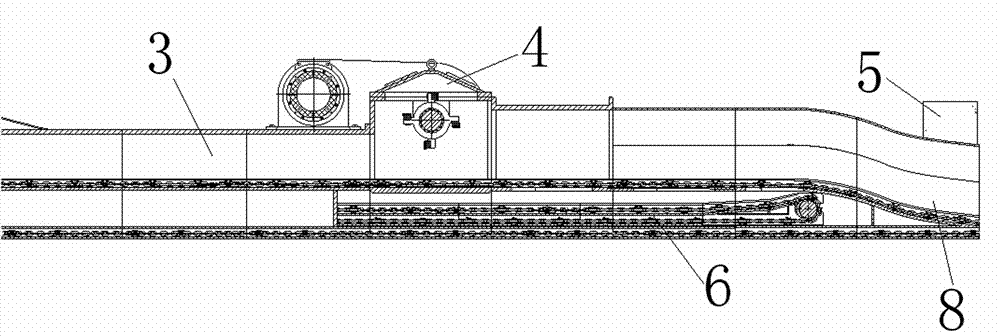

[0022] Such as figure 1 , 2 As shown in the figure, a device for increasing the coal lump rate includes a flexible double-medium chain scraper conveyor, a crusher, and a reloading machine; 4 meters rises up to become the uplift section 3 of the transfer machine, on which a crusher 4 is arranged, and the tail end of the flexible double-medium chain scraper conveyor 8 is the uplift section of the transfer machine, and the transport slot on the uplift section of the scraper transfer machine is opened. There are sorting ports 9, 10, 11, and the transfer machine uplift section 3 is connected with the transfer machine bridge section to form a bridge type transfer machine, under which a sorting transport section 6 is arranged, and the sorting transport section is sideways and raised, and its The end is higher than the landing section 7, and the unloading end is provided with a side slide bucket 12 and communicates with the landing section 7. The transfer machine described above is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com