Optical component and manufacturing method thereof

A manufacturing method and technology for optical components, applied in the field of optical communication, can solve problems such as affecting transmission signals, and achieve the effects of high-speed transmission with large bandwidth, simplified wiring design, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

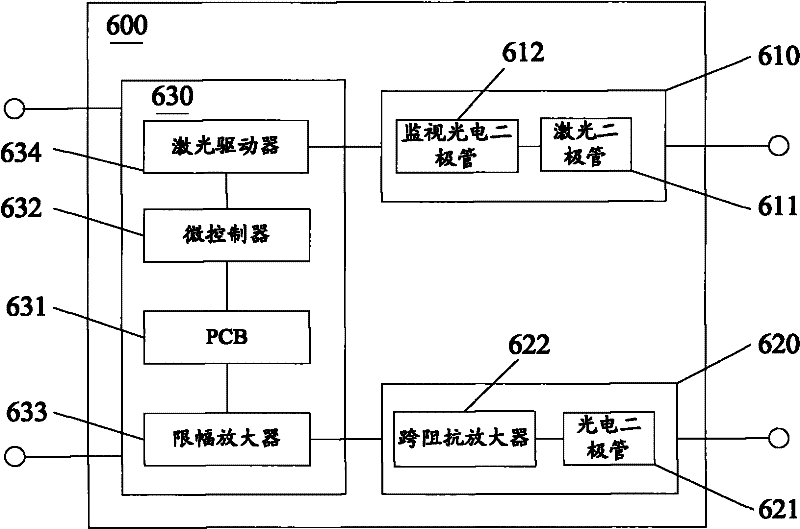

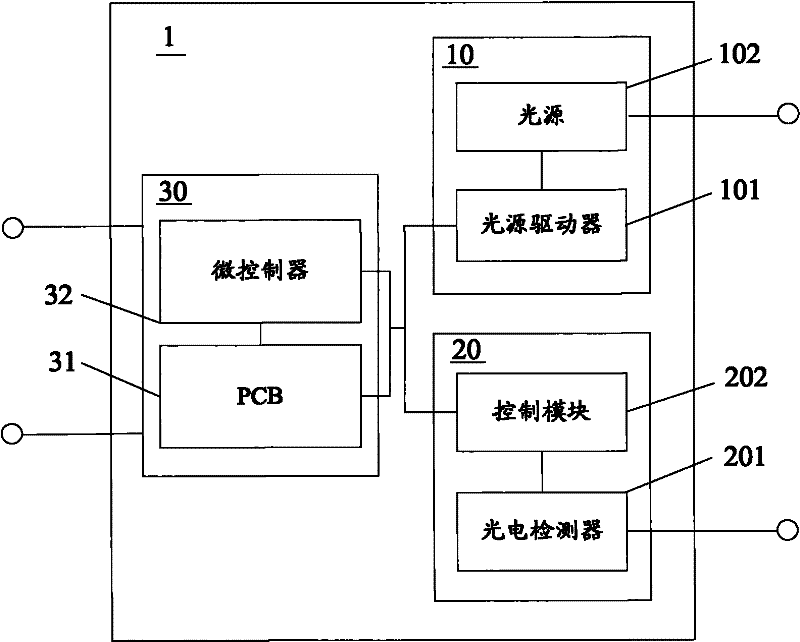

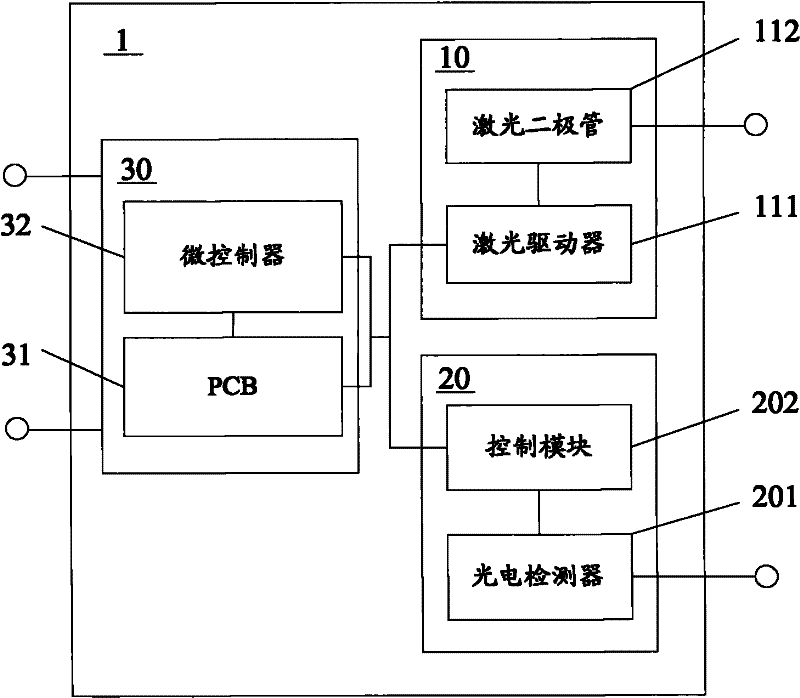

[0042] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention is to integrate the transimpedance amplifier and the limiting amplifier into a control module, and embed it into the ROSA, and integrate the laser driver into the TOSA. This design makes optical components highly integrated to meet the requirements of high-speed transmission and large bandwidth in optical-electrical and electrical-optical conversion. On the other hand, since only the microcontroller IC is mounted on the PCB, the wiring design of the PCB is simplified, for example, the number of wiring layers can be reduced to four layers, while the prior art requires at least six layers. In addition, since the number of ICs is reduced, manufacturing costs are reduced accordingly. In addition, the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com