Ladle conveyor trolley

A technology for conveying trolleys and ladles, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of equipment cost increase and installation space increase, and prevent temperature drop, reduce temperature drop, reduce The effect of casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

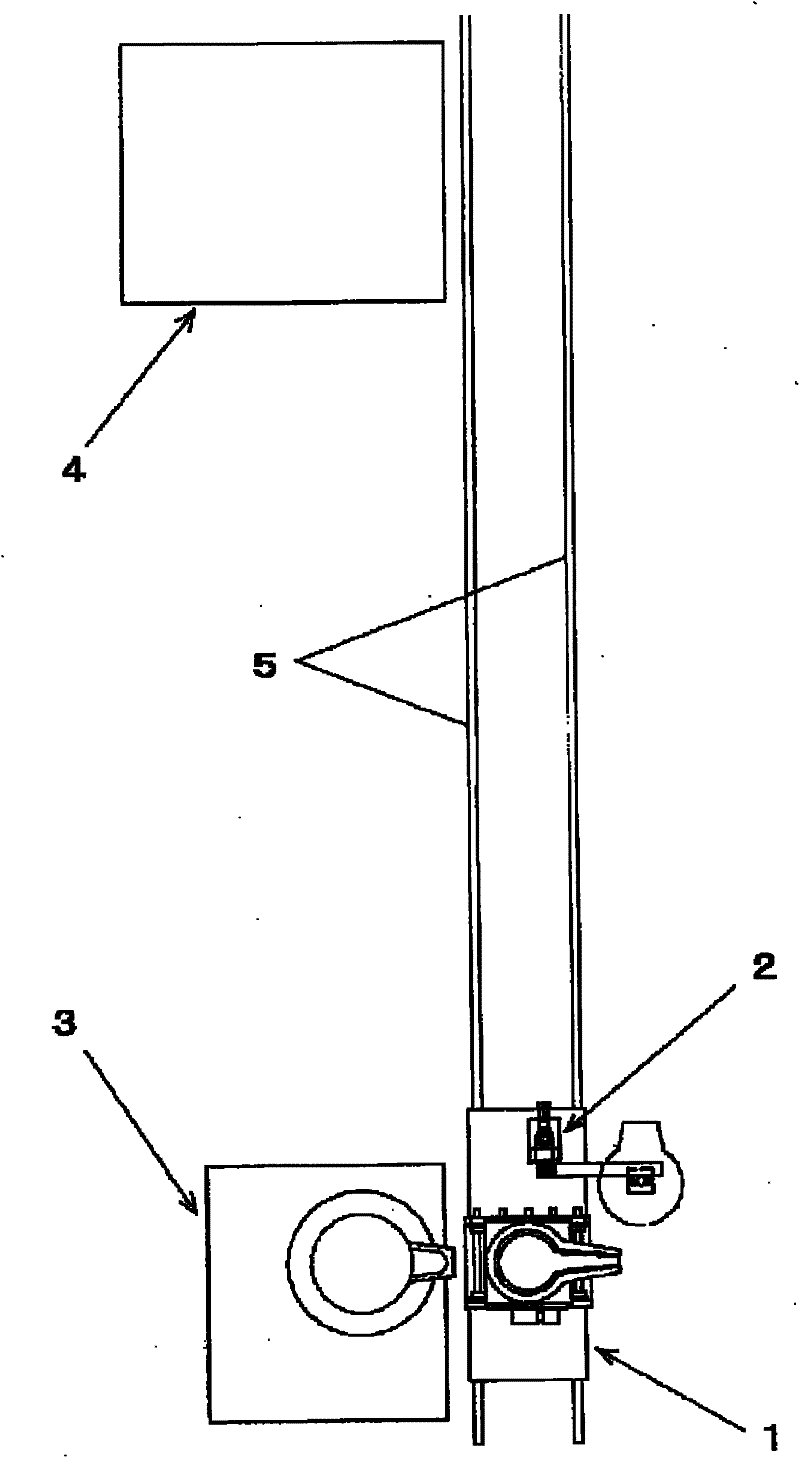

[0027] Hereinafter, the operation|movement of the ladle conveyance trolley 1 comprised as mentioned above is demonstrated. Such as Figure 1 to Figure 3 As shown, when the ladle A, which has been empty since it was conveyed to the pouring equipment 4, receives a command from the control device of the production line, it operates the lid opening and closing device 2 to open the lid B. , while being transported to the melting device 3 by the ladle transport trolley 1 .

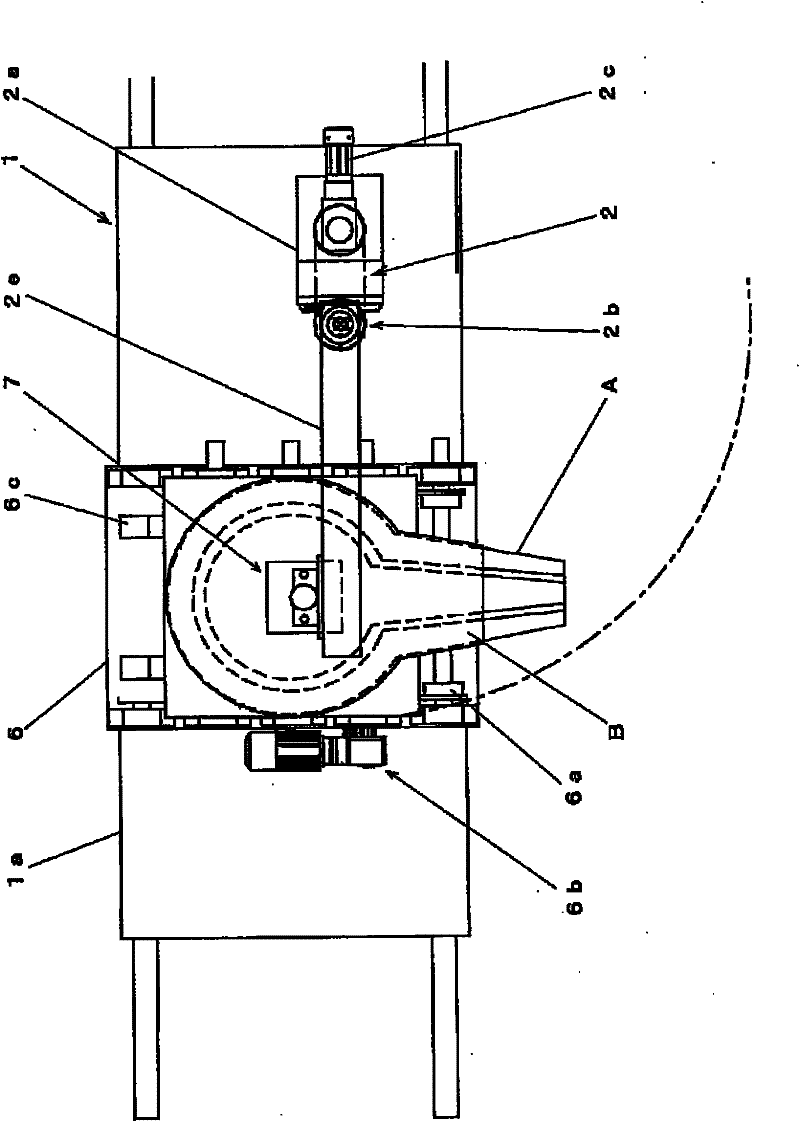

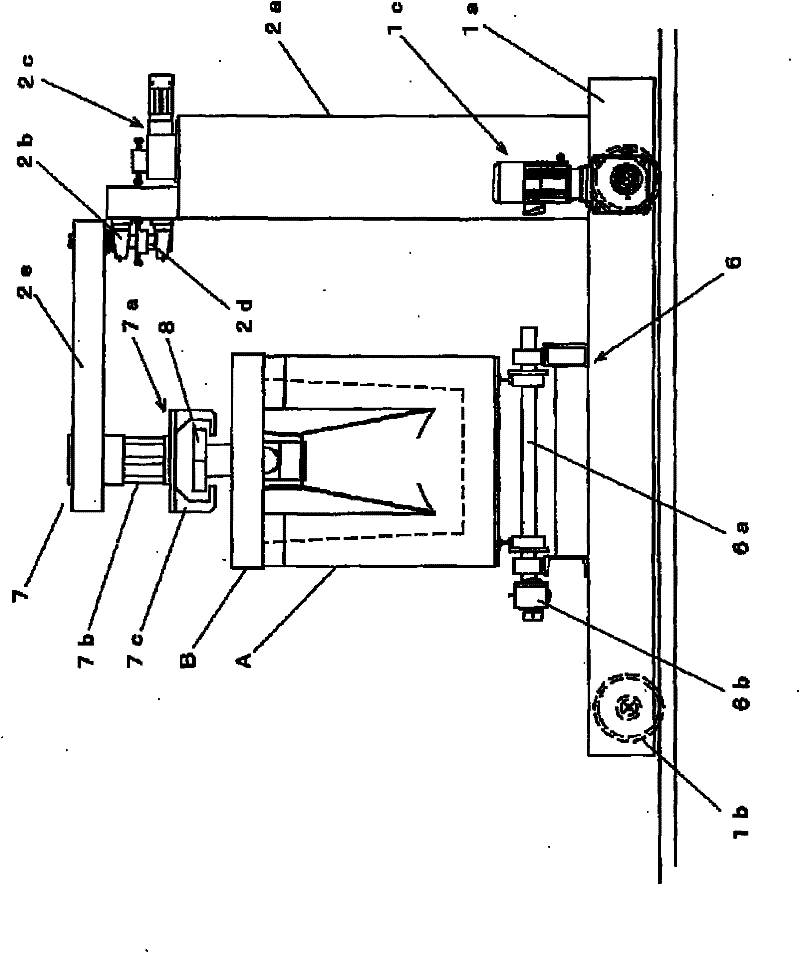

[0028] Such as Figure 4 and Figure 5 As shown, regarding the opening operation of the lid B, the gripping mechanism 7a of the lid lifting mechanism 7 is lowered to the lowering end by operating the actuator 7b. Next, the arm 2e of the lid opening and closing device 2 is swiveled on the lid B placed on the ladle A by the rotating shaft drive mechanism 2c, and then moved to the position where the T-shape of the lid holding member 8 and the holding member 7c are aligned. Where the hook shape snaps.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com