Welded structure with excellent resistance to brittle crack propagation

A brittle crack propagation and structure technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of prolonging the process time, increasing the manufacturing cost, reducing the strength of the structure, etc., and achieving high production efficiency , high security, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0070]

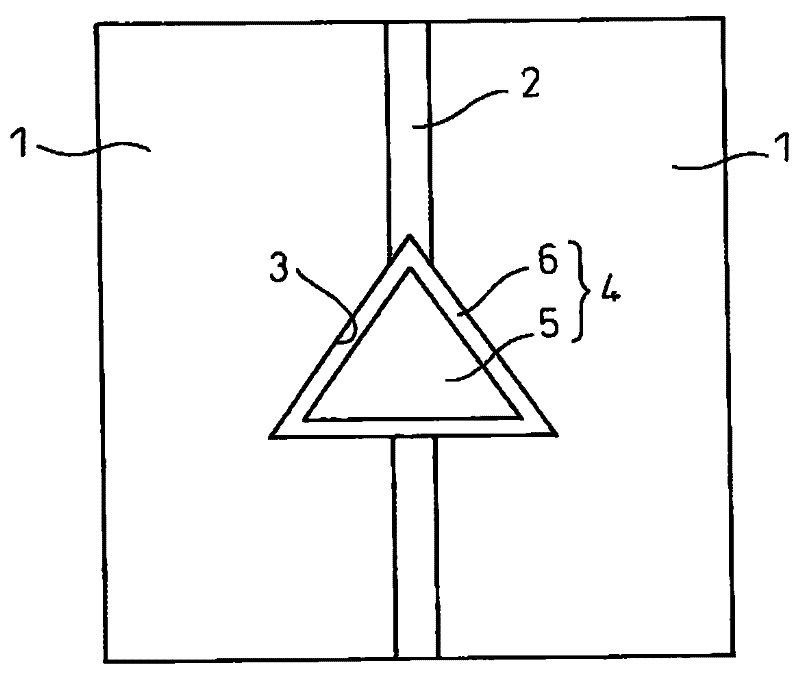

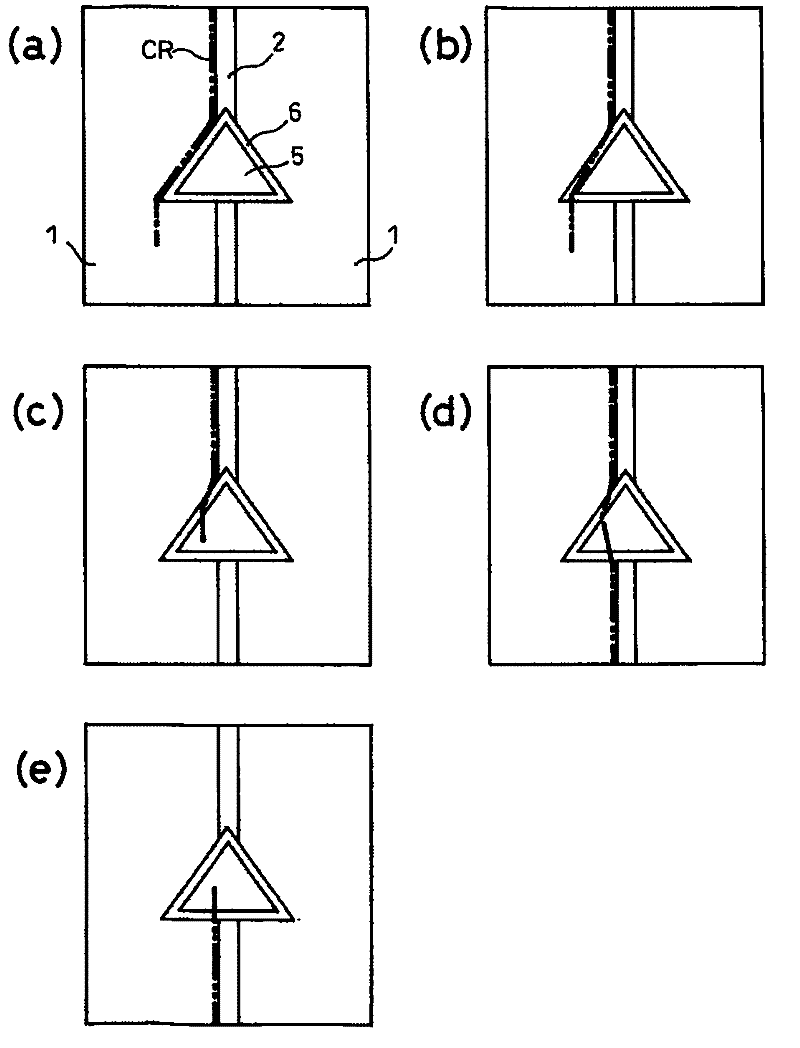

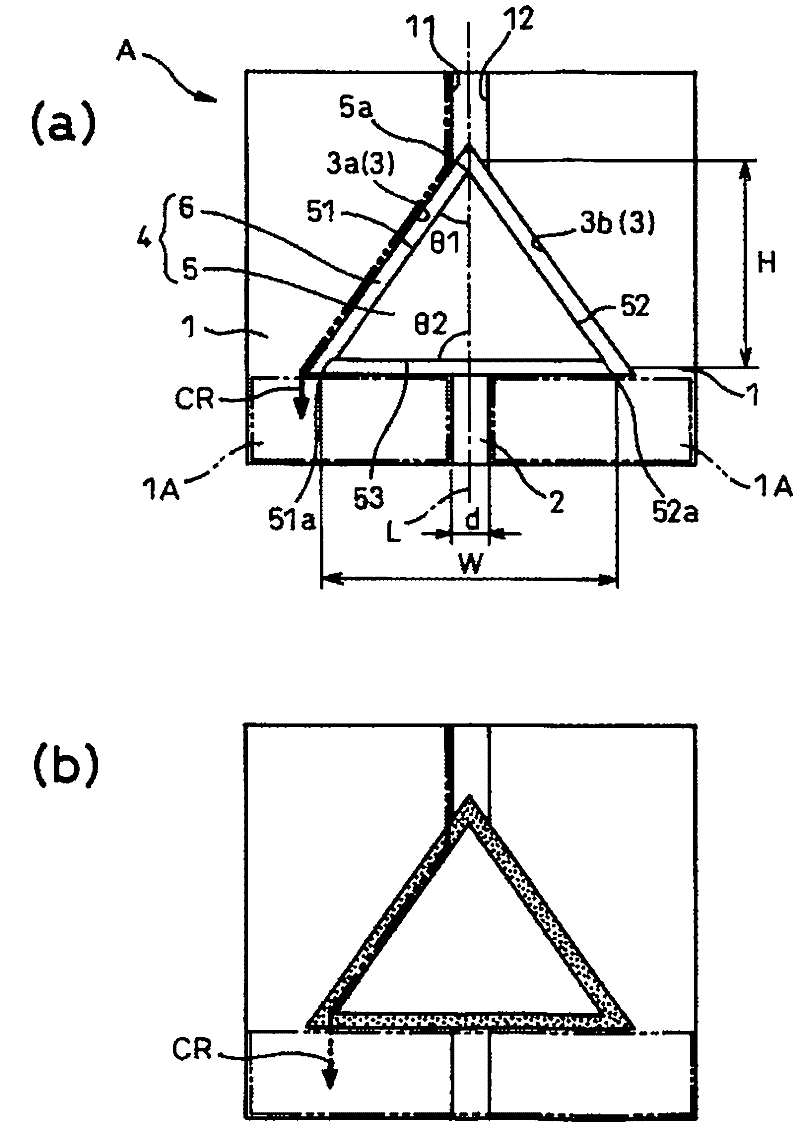

[0071] Such as image 3 As shown, in the first embodiment, the brittle crack propagation arrest characteristic Kca of at least a part of the base material regions 1A and 1A is set to 4000 N / mm 1.5 An example of the case where the above-mentioned steel plates 1 and 1 are butt-welded to form the steel plate welded joint 2 will be described below by referring to a form applied to the joint as a welded structure A.

[0072] In the welded structure A, at least one part of the steel plate welded joint 2 is provided with a crack resistance control part 4 adjacent to the above-mentioned region 1A. The position where the anti-crack control unit 4 is installed is preferably in the middle of a welded joint of steel plates where cracks are expected to occur and propagate when exposed to large destructive energy due to collisions or earthquakes.

[0073] The anti-crack control part 4 is composed of the preventing member 5 and the preventing weld joint 6, the preventing member 5...

no. 2 Embodiment approach

[0151] The main reference below Figure 6 The welded structure B according to the second embodiment of the present invention will be described in detail. In addition, in the following description, the same code|symbol is attached|subjected to the same structure as the welded structure A of the said 1st Embodiment, and detailed description is abbreviate|omitted. In addition, the same applies to the description of the third and fourth embodiments.

[0152] The welded structure B of the present embodiment is Figure 6 The detailed illustration is omitted in , but the brittle crack propagation stop characteristic Kca of the entire base material of the steel plate 10 is set to 4000N / mm 1.5 This point is different from the welded structure A of the first embodiment.

[0153] According to the welded structure B, when a brittle crack is generated in the welded joint 20 of the steel plate, the crack propagating in the welded joint 20 of the steel plate can be propagated along the he...

no. 3 Embodiment approach

[0157] The main reference below Figure 7 A welded structure C according to a third embodiment of the present invention will be described in detail.

[0158] The butt-welded steel plate of the welded structure C is an example when a plurality of small steel plates are butt-welded.

[0159] That is, if Figure 7 As shown, the steel plate 10A is at least two or more small steel plates arranged in the longitudinal direction of the steel plate welding joint 20A (refer to Figure 7 Symbols 21 to 24 in ) are formed by butt welding, and the crack resistance control part 4 is provided in the steel plate welded joint 20A formed by butt welding the steel plates 10A and 10A.

[0160] Small steel plate welded joints 25 , 26 are formed between the small steel plates 21 , 22 , and the preventive weld joint 6 formed on the lower edge portion 53 side of the preventive member 5 is provided in contact with the small steel plate welded joints 25 , 26 . Therefore, in the welded structure C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com