A method of manufacturing an oxygenator

A manufacturing method and aeration machine technology, applied in the field of fishery machinery, can solve the problems of high power consumption and poor oxygenation effect, and achieve the effects of high effective power, expanded range, and remarkable oxygenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

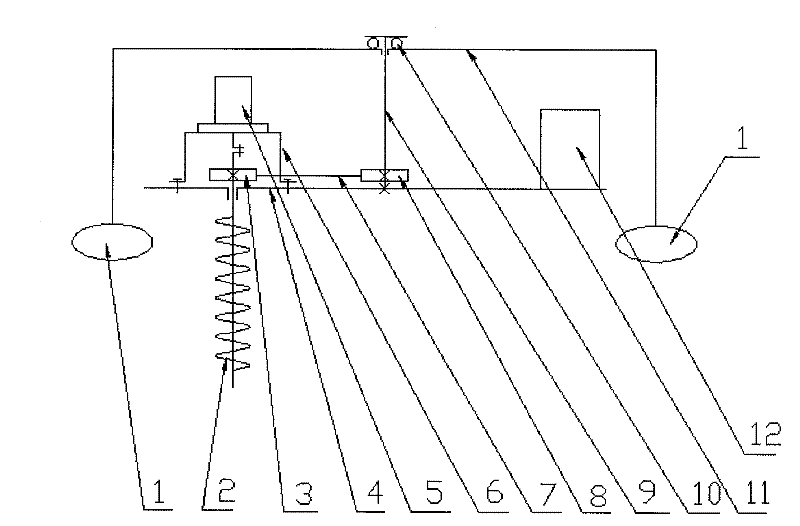

[0008] Install and fix the fixed frame (11) on the buoy (1), install and fix the central shaft (9) on the middle position of the fixed frame (11) through the bearing (10), ensure that the central shaft (9) has a The degree of freedom of frame (11) rotation, below the center shaft (9), a fixed center sprocket (8) is installed, and on the center shaft (9) below the center sprocket (8), a fixed rotating frame (4 ), at one end of the rotating frame (4), the screw blade shaft (2) is installed to ensure that the screw blade shaft (2) has the degree of freedom to rotate relative to the rotating frame (4), and the screw shaft above the rotating frame (4) Install and fix the transmission sprocket (3) on the blade shaft (2), install and fix the motor (5) above the screw blade shaft (2) through the motor bracket (6), and connect the output shaft of the motor (5) through the shaft coupling The device is connected and fixed to the top of the spiral blade shaft (2), the chain (7) is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com