Low-ammonia-nitrogen super-intensive aquiculture system

A breeding system and low ammonia nitrogen technology, applied in the field of complete sets of factory high-density breeding equipment, can solve the problems of unsightly appearance, low space utilization rate, and large amount of excrement, and achieve high water resource utilization rate, improve utilization rate, Good oxygenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

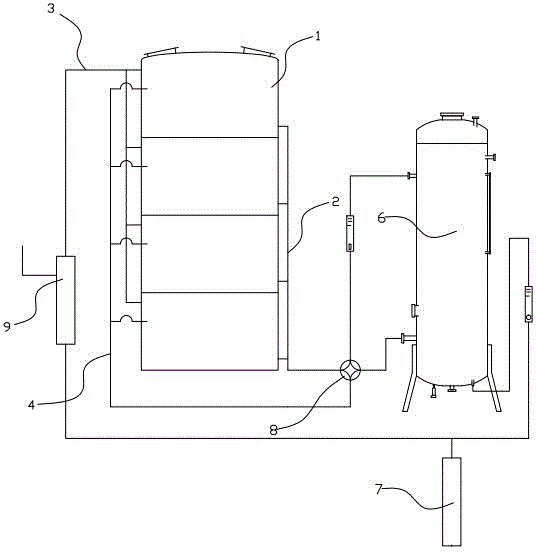

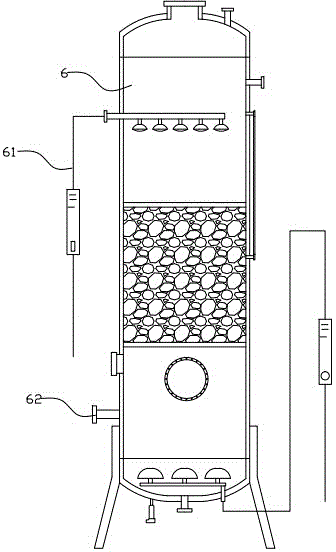

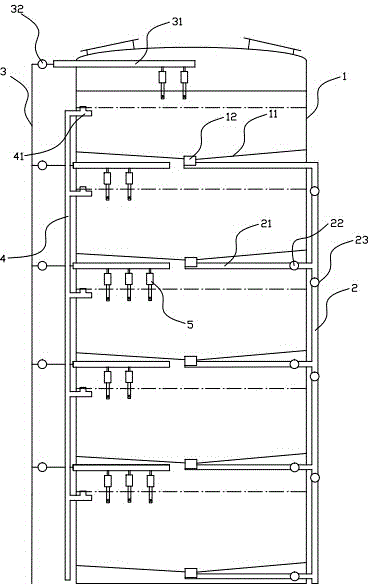

[0015] Example: refer to Figure 1 to Figure 6, a low ammonia nitrogen super-intensive culture system, including an oxidation tower 6 connected to a culture container, wherein: the culture container is a column-shaped culture tank 1; The funnel-shaped separation layer 11 of the large and small inner cavity; the bottom of the separation layer 11 is provided with an electric control drain valve 12; the electric control drain valve 12 is connected to the drain pipe 2 arranged on the side of the culture tank 1 through the drain branch pipe 21; Also be provided with inflatable branch pipe 31, and this inflatable branch pipe 31 is connected with rotary aerator 5; Inflatable branch pipe 31 is connected with air pump 9 through inflatable pipe 3; Culture tank body 1 side runs through and is provided with water inlet overflow branch pipe 41; The overflow branch pipe 41 is connected with the water inlet overflow pipe 4; the drain pipe 2, the water inlet overflow pipe 4 are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com