Forming method of train axle forging

A technology for train shafts and forgings, which is applied in the field of metal plastic forming technology, can solve the problems of high product price, insignificant improvement in product quality, slow production speed, etc., and achieve the goal of improving material utilization, excellent product quality and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The method for forming train axle forgings of the present invention, its preferred embodiment is:

[0018] Including four passes of roll forging, including steps:

[0019] The roll forging dies of the first pass, the second pass, the third pass and the fourth pass are installed sequentially on the forging rollers of the roll forging machine;

[0020] Send the billet heated to 1150-1200°C to the feeding platform in front of the roll forging machine, and the manipulator of the roll forging machine clamps one end of the billet with a large jaw, and performs the first pass, the second pass, and the third pass in sequence The first and fourth passes of roll forging, after each pass of roll forging, the billet is rotated 90° before the next pass of roll forging;

[0021] When the fourth pass of roll forging is completed, the large jaw of the manipulator is loosened, and the billet is turned around 180°. The clamped part is sequentially subjected to the first pass, the secon...

specific Embodiment

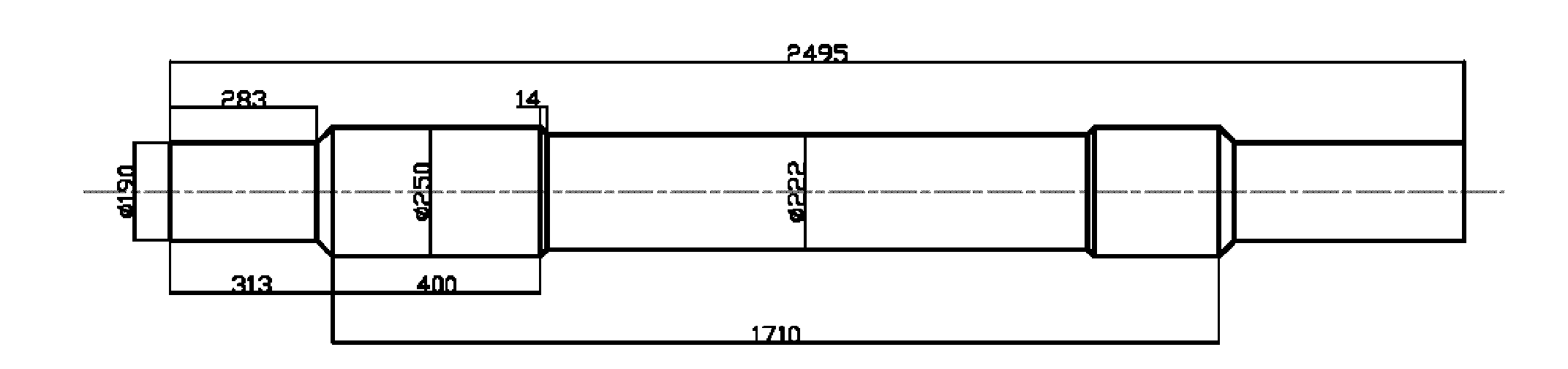

[0032] figure 1 It is a diagram of a train shaft forging. The maximum diameter in the figure is 250 mm, the minimum diameter is 190 mm, and the total elongation is 1.73. The main deformation can be completed in two passes, and the third and fourth passes are used for shaping. In order to ensure that the entire length of the forging is deformed and eliminate the coarse part of the grain, the raw material is taken as a round billet with a diameter of 290 mm, so that the elongation of the largest diameter is also 1.35. If square billet is used, the side length is 257 mm.

[0033] like Figure 2a to Figure 2i As shown, fan modules are installed on two rolls of a roll forging machine with a center distance of 1500 mm. The four-pass roller forging dies are installed on the forging rollers sequentially, and the upper and lower roller forging die modules are the same. The billet heated to 1150-1200°C is sent to the material pressing platform in front of the roll forging machine thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com