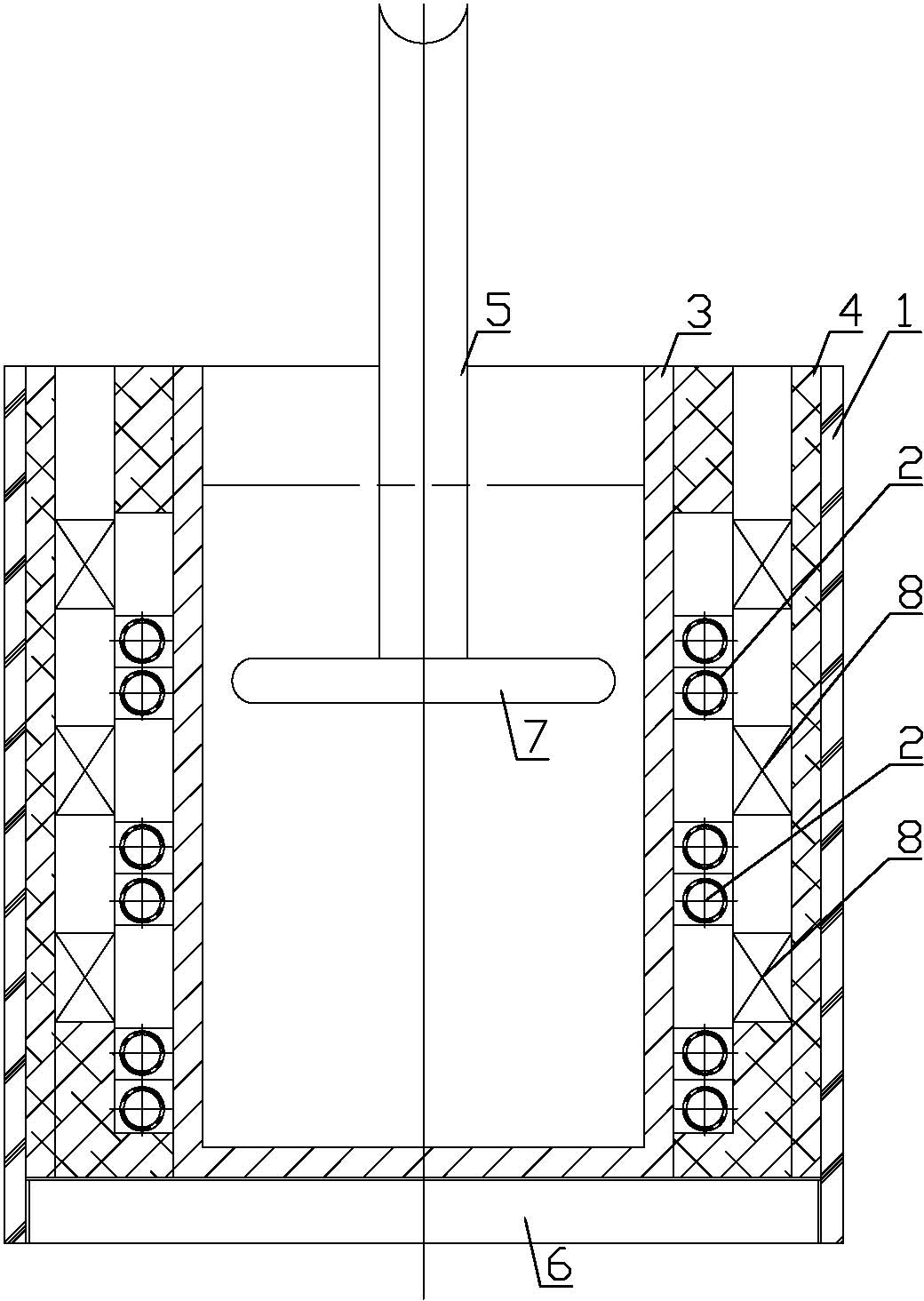

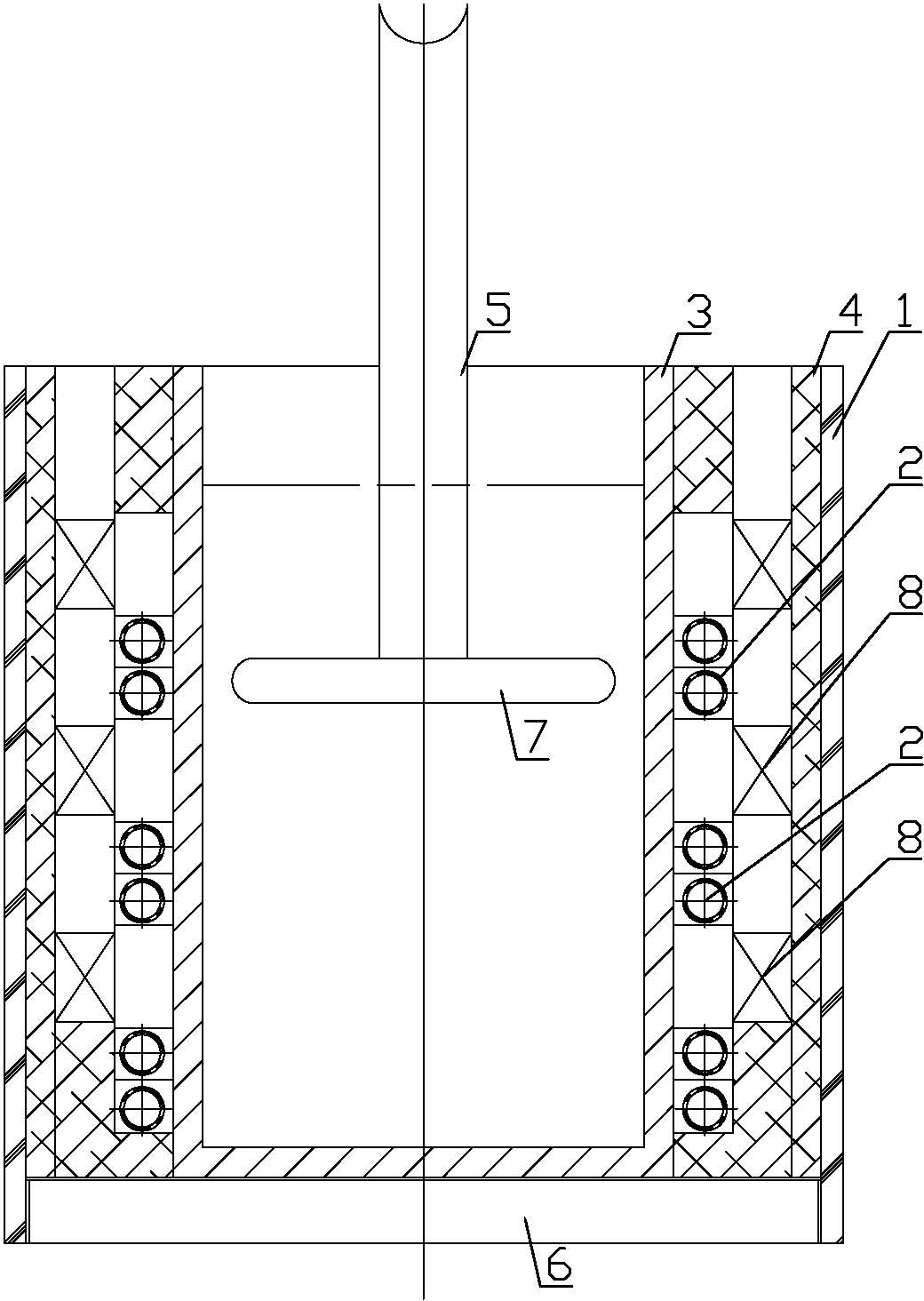

Method for Purifying High-purity Aluminum by Directional Solidification and Its Melting Furnace

A technology for directional solidification and smelting furnaces, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems of high cost, low efficiency and high energy consumption, and achieve the effects of large processing capacity, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the method for purifying high-purity aluminum by directional solidification is carried out according to the following steps:

[0030] The first step is to select materials, select aluminum raw materials with a purity of 4N to 4N5, and physically clean the surface of the above-mentioned aluminum raw materials;

[0031] In the second step, smelting, put the aluminum raw material prepared in the first step into the refining container of the smelting furnace, heat the aluminum raw material to 670°C to 730°C, and melt all the aluminum raw material to obtain aluminum liquid;

[0032] The third step is solidification and purification. The aluminum liquid obtained in the second step is allowed to stand at 670°C to 730°C for 7 minutes to 80 minutes; then the bottom of the melting furnace is cooled, and the aluminum liquid is heated to make the aluminum liquid temperature Control the temperature from low to high in the range of 660°C to 700°C from the crysta...

Embodiment 2

[0034] Embodiment 2, the method for purifying high-purity aluminum by directional solidification is carried out according to the following steps:

[0035] The first step is to select materials, select aluminum raw materials with a purity of 4N5 to 5N, and physically clean the surface of the above aluminum raw materials;

[0036] In the second step, smelting, put the aluminum raw material prepared in the first step into the refining container of the smelting furnace, heat the aluminum raw material to 670°C or 730°C, and melt all the aluminum raw material to obtain aluminum liquid;

[0037] The third step is solidification and purification. The aluminum liquid obtained in the second step is allowed to stand at 670°C or 730°C for 7 minutes or 80 minutes; Control the range of 660°C or 700°C from low to high from the crystallization side up, crystallize from the bottom of the furnace upward, and obtain a crystallized ingot after 1 hour or 8 hours. During the crystallization...

Embodiment 3

[0039] Embodiment 3 is different from Embodiment 1 and Embodiment 2 in that: the stirring paddle of the stirrer in Embodiment 3 is stirred by rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com