Slurry pressurized shield construction method and construction equipment for mesh cutter head

A construction method and grid technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large surface subsidence or uplift, small applicable range of stratum, and inability to control the stability of excavation surface well, etc. To meet the requirements of surface settlement, control the stability of the excavation surface, and achieve the effect of small settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

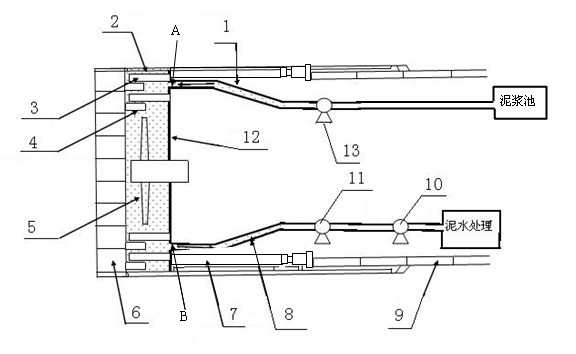

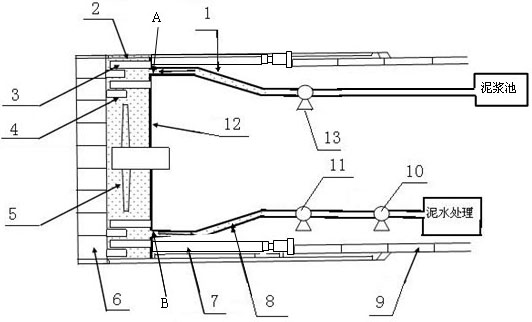

[0016] Control attached figure 1 , its structure includes feeding mud pipe 1, pressure chamber 2, fixed wing 3, grid back stirring wing 4, independently driven stirring wing 5, front grid 6, shield jack 7, mud discharge pipe 8, segment 9, Relay pump 10, mud discharge pump 11, partition 12, and mud inlet pump 13, wherein one end of the soil pipe 1 is connected to the mud tank through the mud inlet pump 13, and the other end of the soil pipe 1 is connected to the A inlet of the partition 12 On the upper part of the pressure chamber 2, the agitating wing 4 on the back of the grid in the pressure chamber 2 is arranged between the fixed wing 3 and the 5 independently driven agitating wings, and one end of the mud discharge pipe 8 is connected to the lower part of the pressure chamber 2 through the outlet B of the partition 12 , the other end of the mud discharge pipe 8 is connected to the mud water treatment tank through the relay pump 10 and the mud discharge pump 11, the front gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com