Multistage compressed gas engine and motor vehicle

A technology for compressing gas and engine, which is applied in the field of machinery to achieve the effect of improving energy utilization, good noise reduction and good force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

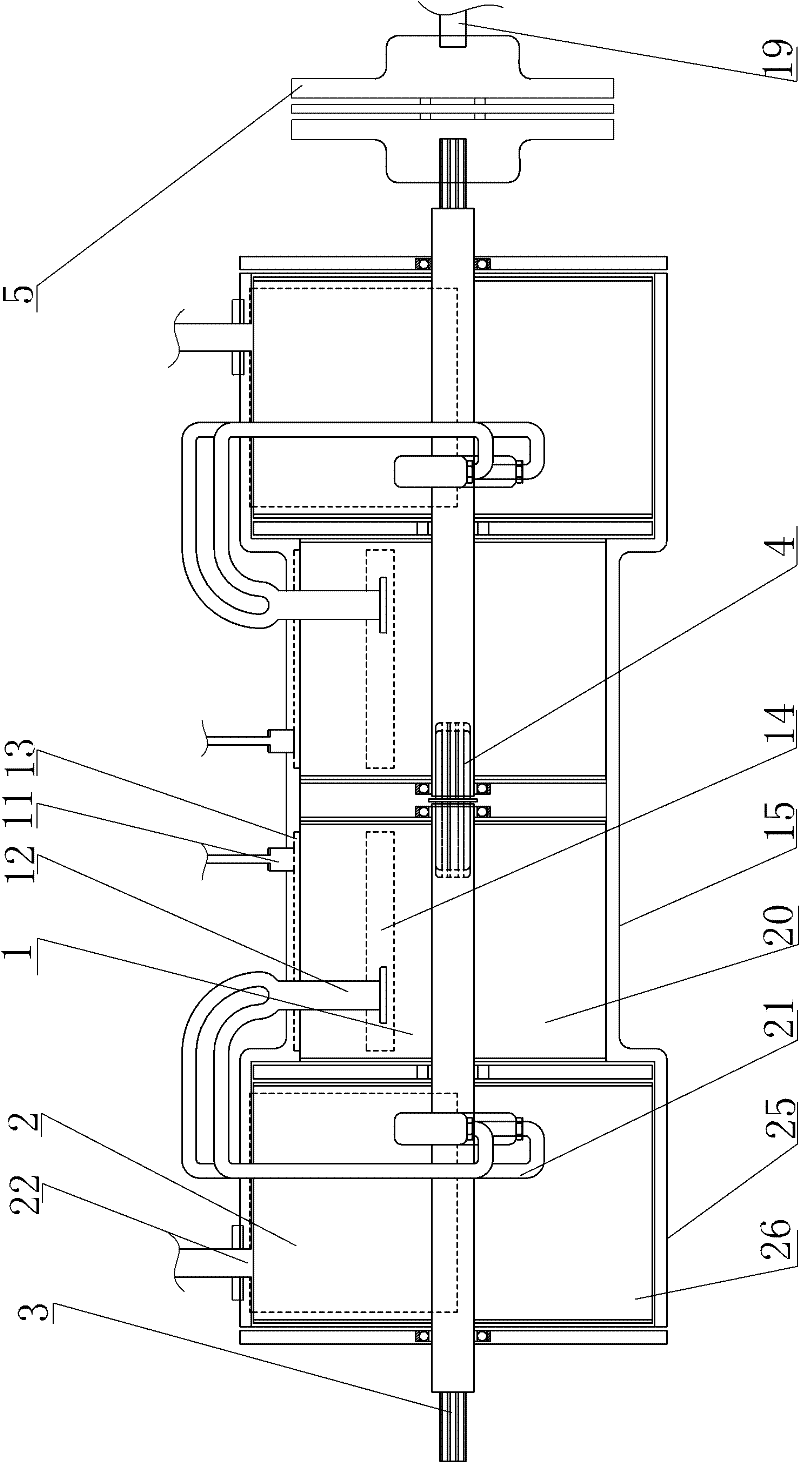

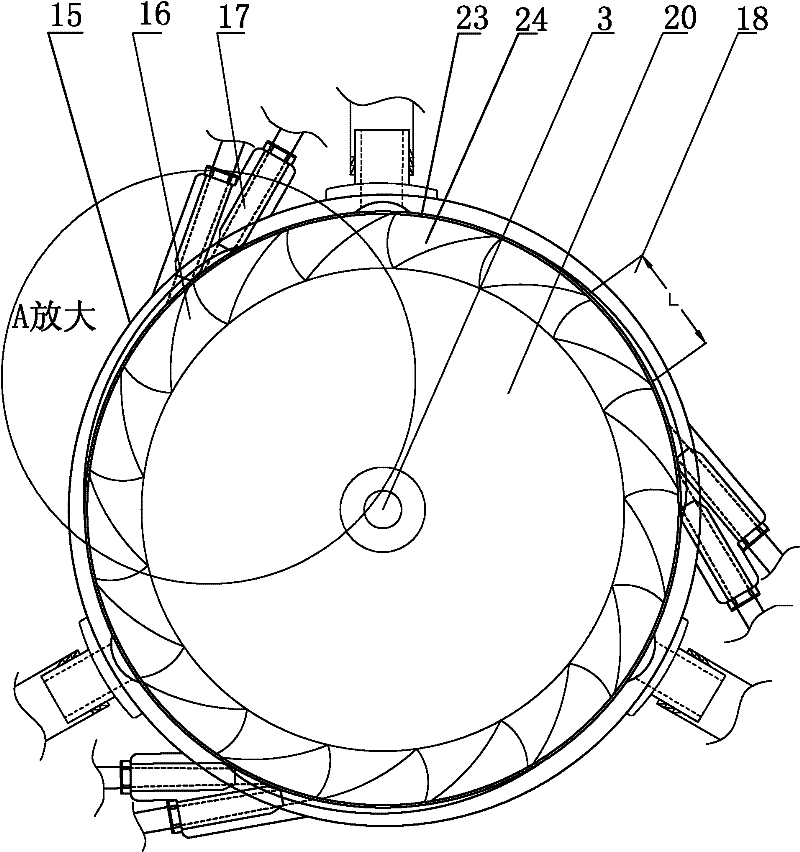

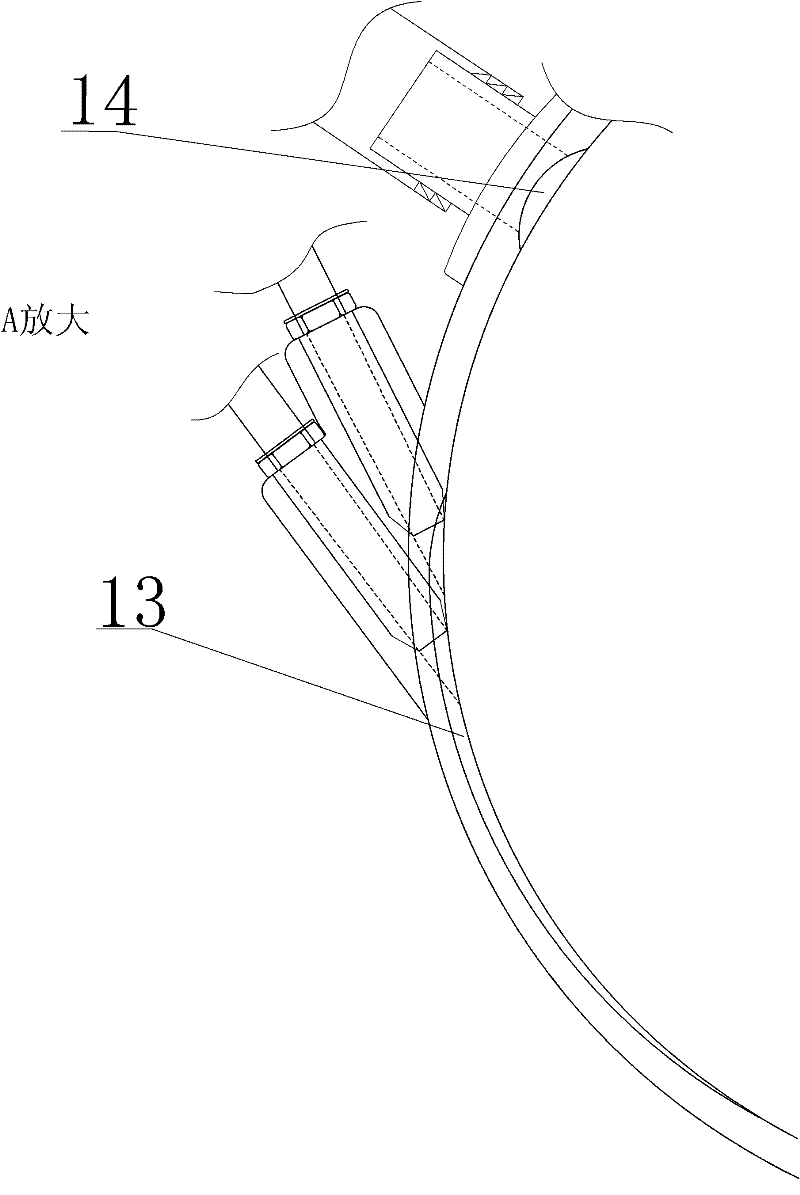

[0036] Embodiment one, a kind of motor vehicle, such as Figure 1 to Figure 3 As shown, it includes a two-stage compressed gas engine and a transmission shaft 19 in a left-right symmetrical structure, wherein the two-stage compressed gas engine on the left side and the two-stage compressed gas engine on the right side have the same structure. Take the two-stage compressed gas engine on the left as an example, including the first-stage compressed gas engine 1 and the second-stage compressed gas engine 2 . The first-stage compressed gas motor 1 includes a first impeller 20 and a first impeller chamber 15, the second-stage compressed gas motor 2 includes a second impeller 26 and a second impeller chamber 25, and the left and right multi-stage compressed gas motors are coaxially installed on the same On the rotating shaft 3, the power generated by the multistage compressed gas engine passes through the rotating shaft 3 and the clutch 5 to transmit the transmission shaft 19 of the ...

Embodiment 2

[0042] Embodiment two, another kind of compressed gas engine, such as Figure 4 Shown, including a two-stage compressed gas engine on the left and a two-stage compressed gas engine on the right. The two-stage compressed gas engine on the left is the first compressed gas engine 100 , and the two-stage compressed gas engine on the right is the second compressed gas engine 200 . The first compressed gas engine 100 and the second compressed gas engine 200 have the same structure and are left-right symmetrical. The first compressed gas motor 100 and the second compressed gas motor 200 are coaxially installed on the rotating shaft 118 and connected through the bearing 108 and the spline sleeve 117 . The power generated by the two-stage compressed gas engines on the left and right sides is output through the rotating shaft 118, and is used to drive the transmission shaft of the motor vehicle.

[0043] Taking the first compressed gas engine 100 as an example, the first compressed ga...

Embodiment 3

[0049] Embodiment three, another kind of multi-stage compressed gas engine, such as Figure 5 Shown, including a two-stage compressed gas engine on the left and a two-stage compressed gas engine on the right. The two-stage compressed gas motor on the left is the first compressed gas motor 300 , and the two-stage compressed gas motor on the right is the second compressed gas motor 400 . The first compressed gas engine 300 and the second compressed gas engine 400 have the same structure and are left-right symmetrical. The first compressed gas motor 100 and the second compressed gas motor 200 are coaxially installed on the rotating shaft 318 and connected through the bearing 308 and the spline sleeve 317 . The power generated by the two-stage compressed gas engines on the left and right sides is output through the rotating shaft 318, and is used to drive the transmission shaft of the motor vehicle.

[0050] Taking the first compressed gas engine 300 as an example, the first com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com