Portable filter detector

A portable and detector technology, applied in instruments, measuring devices, etc., can solve problems such as damage to hydraulic components, inaccurate test data, and increased particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

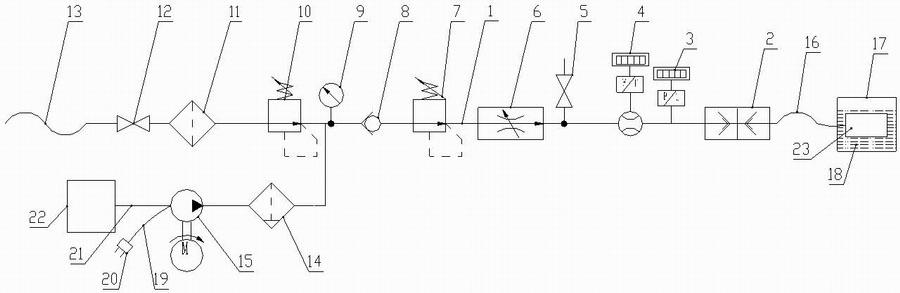

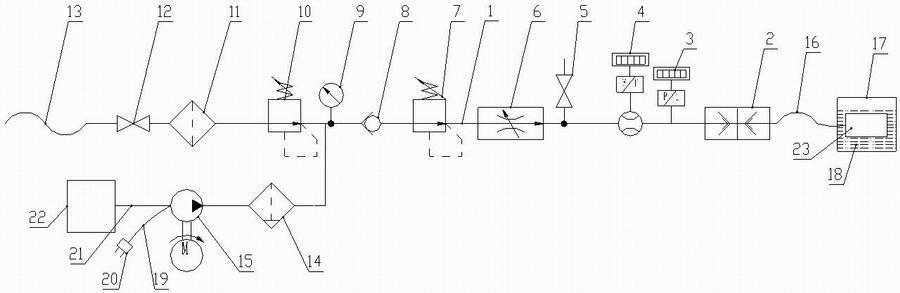

[0009] Such as figure 1 As shown, the portable filter element detector of the present invention includes a detection container 17 and a quick joint 2, a pressure gauge test assembly 3, a flow meter test assembly 4, an exhaust valve 5, a pressure regulating valve 6, a first A pressure reducing valve 7 and a one-way valve 8, the air inlet of the one-way valve 8 is connected in parallel with a gas cylinder air supply device and an air pump air supply device, the air inlet of the one-way valve 8 is connected with a pressure gauge 9, a quick connector 2 A filter element air inlet pipe 16 is connected, and the air outlet of the filter element air inlet pipe 16 stretches into the detection container 17, which is filled with kerosene 18.

[0010] The air supply device for the gas cylinder is the second decompression valve 10 , the air filter assembly 11 , the intake switch 12 and the high-pressure gas cylinder connector 13 which are sequentially connected to the air inlet of the one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com