Straw Compression Bundling Test Device and Test Method

A technology of compression molding and test device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., which can solve the difficulty of changing the feeding amount, no retrieval, and difficulty in the pressure of the side plate and bottom plate of the compression chamber. Obtain and other problems, to achieve the effect of convenient operation, comprehensive detection and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

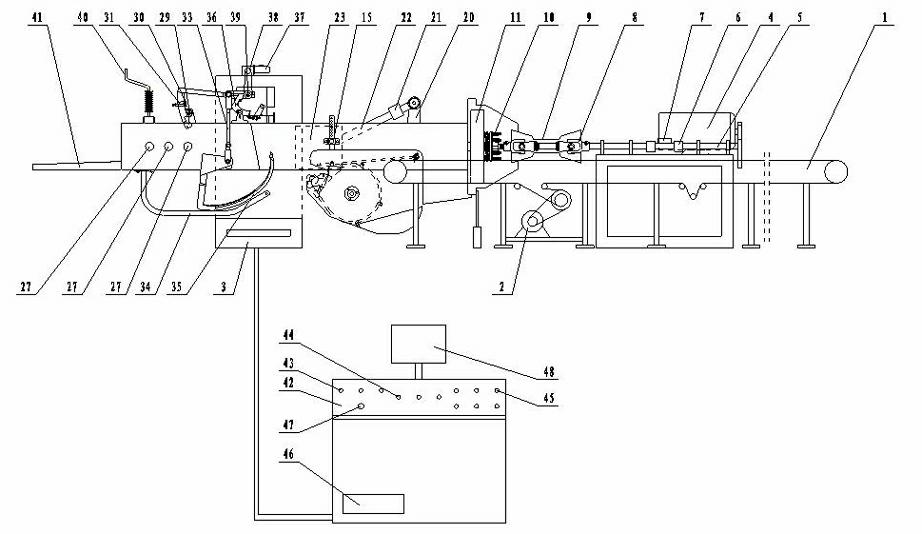

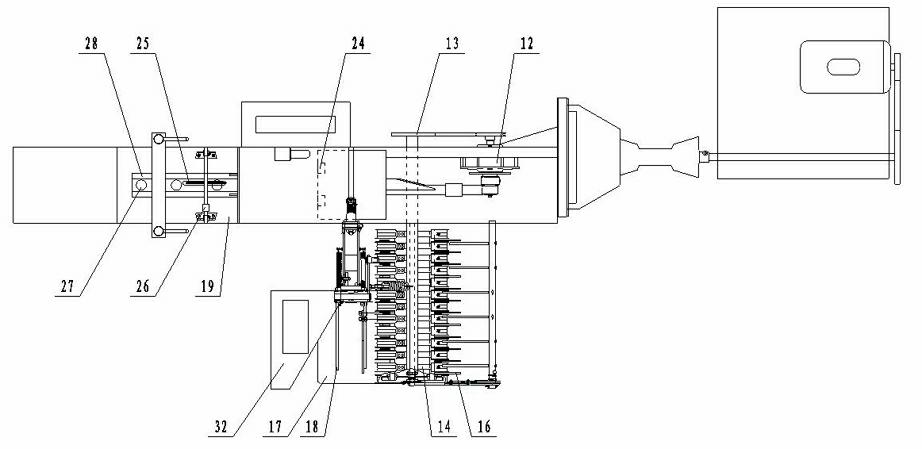

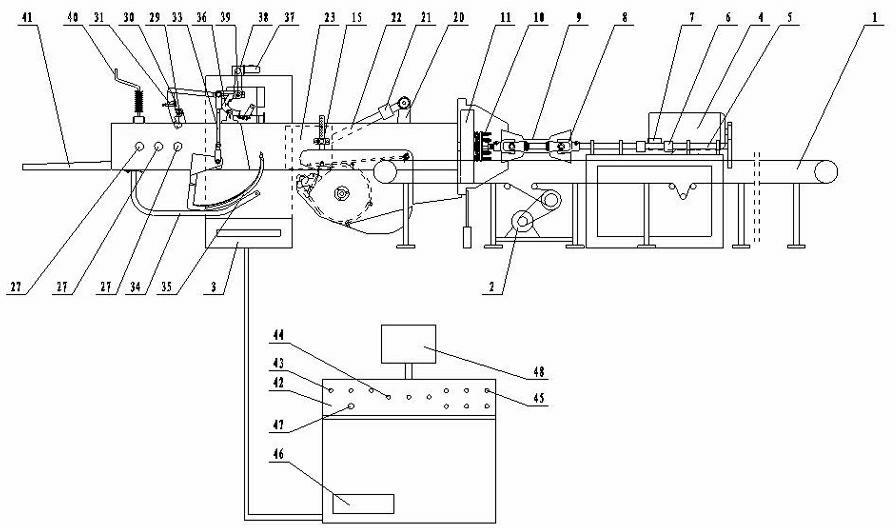

[0026] Such as figure 1 , 2 As shown, it mainly includes material conveying device, packing compression device, binding device and detection and control device. The conveying device includes a conveyer belt driving motor 2, a conveyer belt 1 and a tensioning wheel. During the test, the rotating speed of the motor 2 can be adjusted according to the required feeding amount. The packing compression device includes a frame and a base 3, connected to the power input shaft 5 of the driving motor 4, and a speed-torque sensor 7 is installed on the power input shaft 5, and the transmission torque and the change of the speed are measured during the test. The power input shaft 5 is connected to the main gear box 12, and the main gear box 12 is connected to the pick-up device driving wheel 13 on one side, and the height of the pick-up device can be adjusted by the pick-up device height adjusting device 15; the main gear box 12 is connected to the crank 20 and the connecting rod 22, Ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap