Liquid crystal lens and 3D display device

A liquid crystal lens and display device technology, which is applied in the directions of lenses, static indicators, optics, etc., can solve the problems of not being able to use in the field of naked-eye 3D display, the focal length of the cylindrical lens is not adjustable, and it is difficult to play 2D image switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

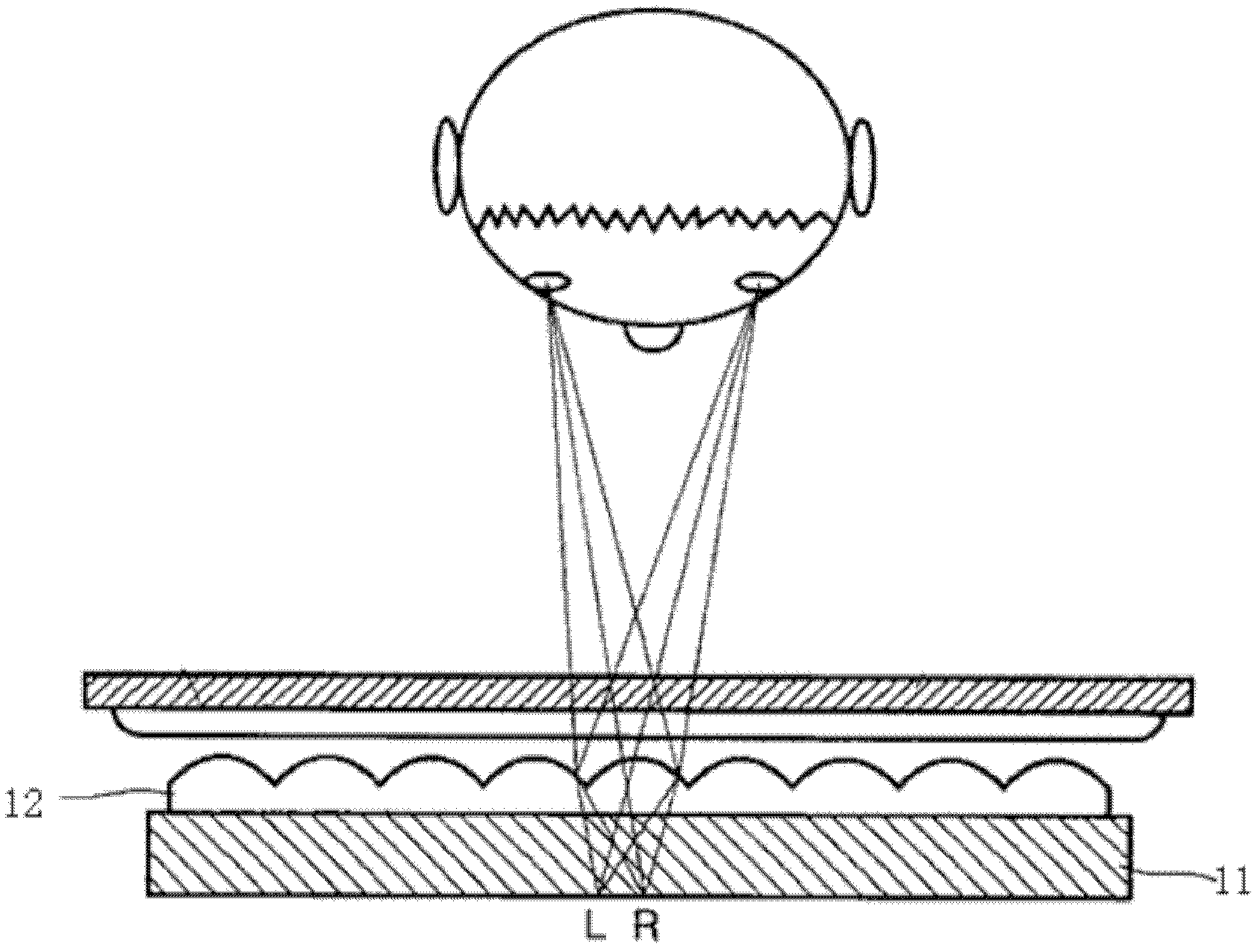

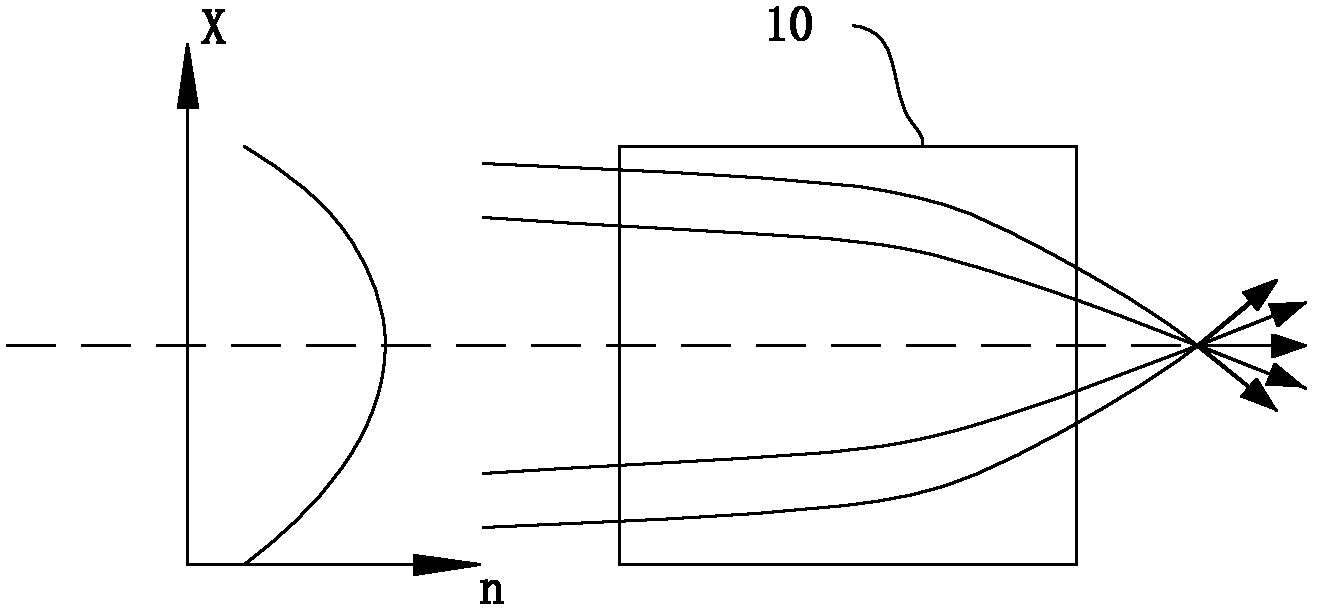

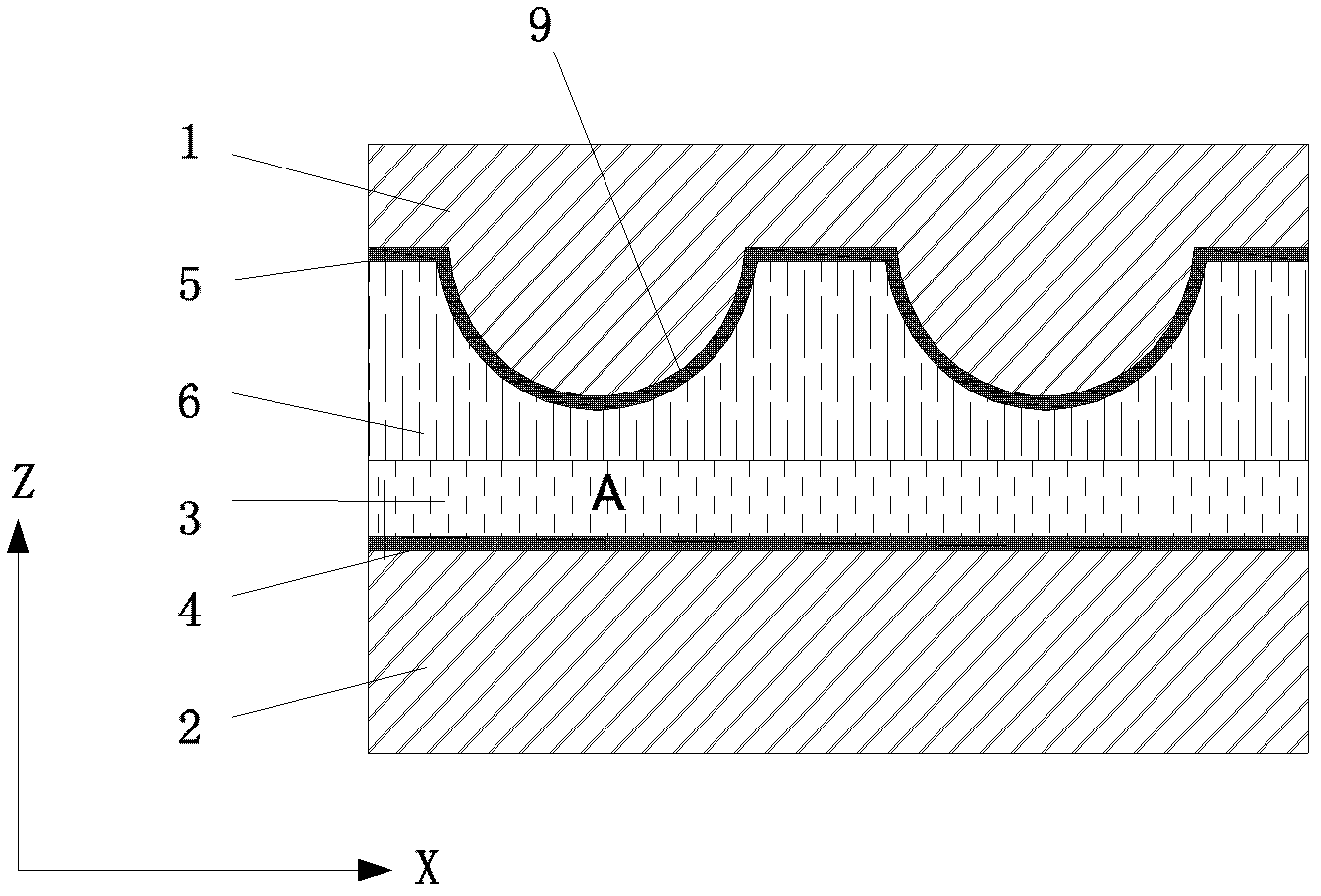

[0035] A liquid crystal display device capable of naked-eye 3D display includes a liquid crystal panel and a liquid crystal lens arranged in front of the liquid crystal panel. The structure of the first embodiment of the liquid crystal lens is as follows: image 3 As shown, the counter electrode 5 of the liquid crystal lens on the upper substrate 1 has a plurality of concave curved surface structures 9 with the same shape and arranged in parallel to make the distance between the electrode and the counter electrode smaller. The vertices are symmetrical and can be in a hemispherical structure; correspondingly, the side of the upper substrate 1 corresponding to the counter electrode 5 has a protruding area with the same structure as the concave curved surface structure 9 . The thickness of the liquid crystal layer is uniform, and an insulating layer 6 is filled between the liquid crystal layer and the protruding counter electrode 5 , so that the counter electrode 5 is insulated fr...

Embodiment 2

[0040] The structure of the liquid crystal lens of the second embodiment is similar to that of the first embodiment, and the difference from the first embodiment is that, as Figure 5 As shown, the electrode 4 of the lower substrate 2 is designed to have a concave curved surface structure 9 that makes the distance between the electrode and the counter electrode smaller. Correspondingly, the side of the lower substrate 2 corresponding to the electrode 4 has a concave surface The convex regions of the curved surface structure 9 are likewise configured. The thickness of the liquid crystal layer is uniform, and an insulating layer 6 is filled between the liquid crystal layer and the protruding electrode 4 , so that the electrode 4 is insulated from the liquid crystal layer 3 . The upper substrate 2 and the counter electrode 5 on it are arranged in a plane, and the liquid crystal adopts a vertical alignment type negative nematic liquid crystal (Negative Nematic LC). The liquid crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com