Contactless power supply device

A non-contact power supply and circuit technology, which is applied in the direction of circuit devices, circuits, inductors, etc., can solve the problems of thick coils, difficulty in configuration, and increased weight, and achieve the effects of thinner coils, easier configuration, and lighter weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

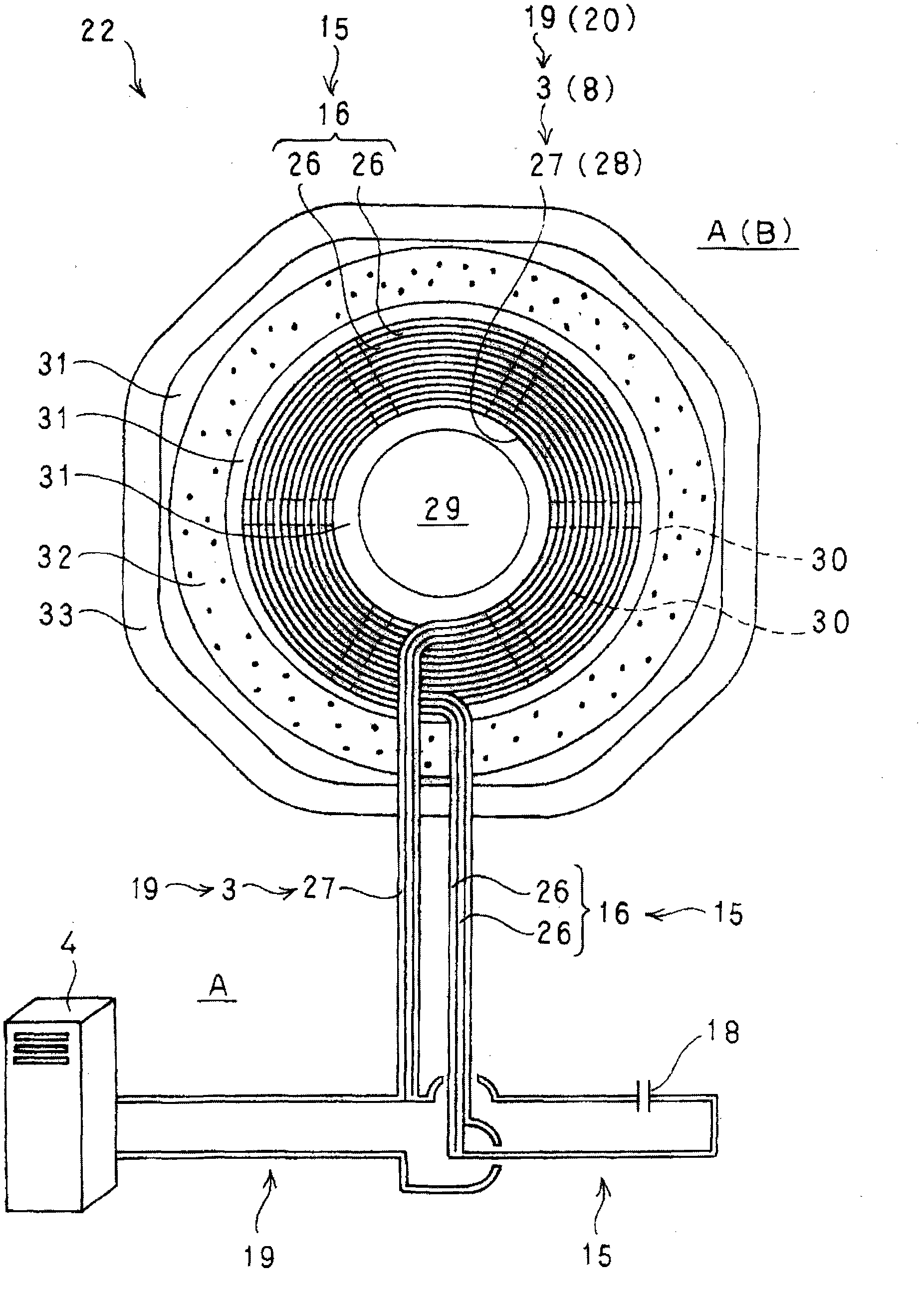

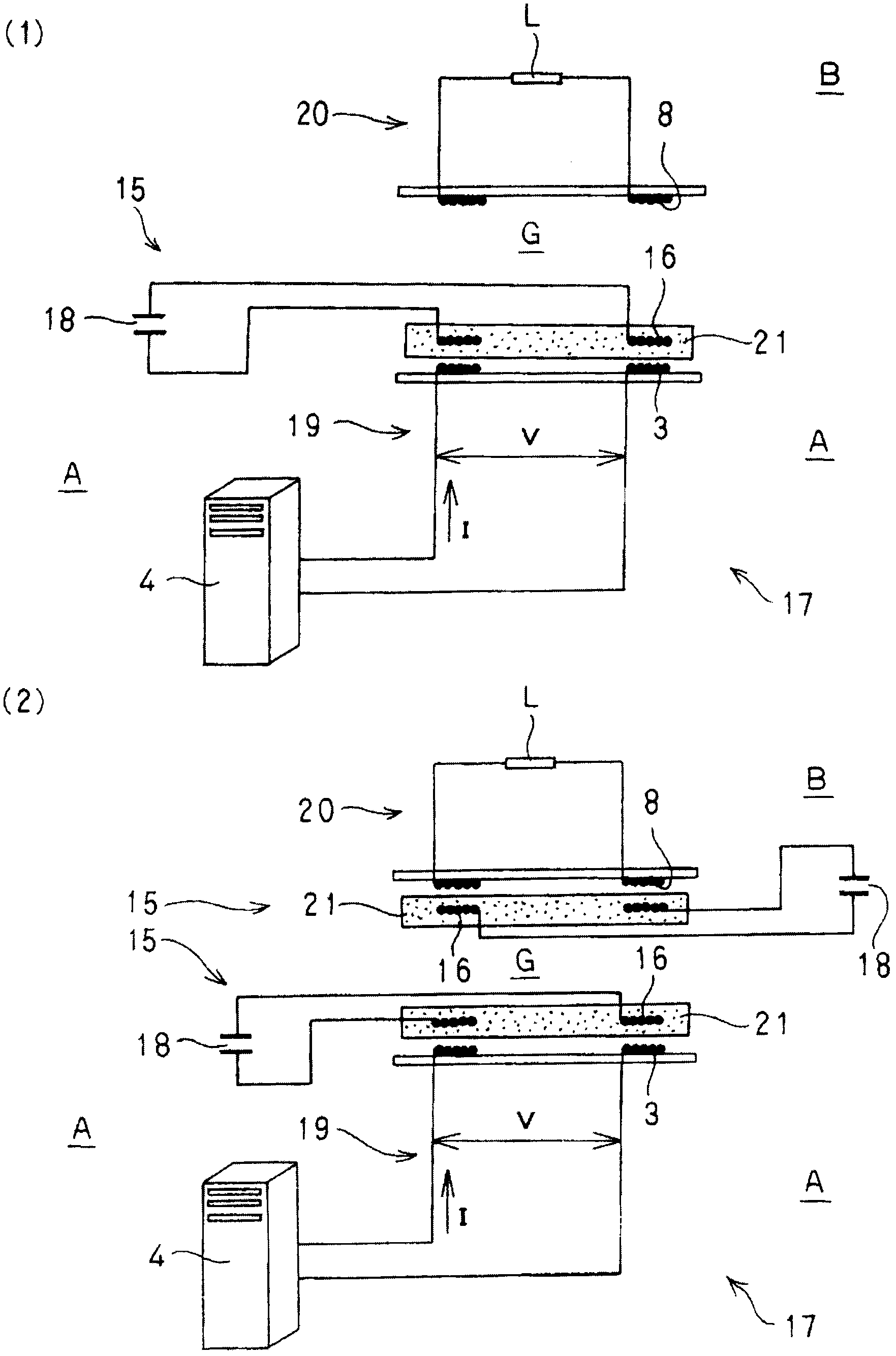

[0130] Here, an embodiment of the present invention will be described.

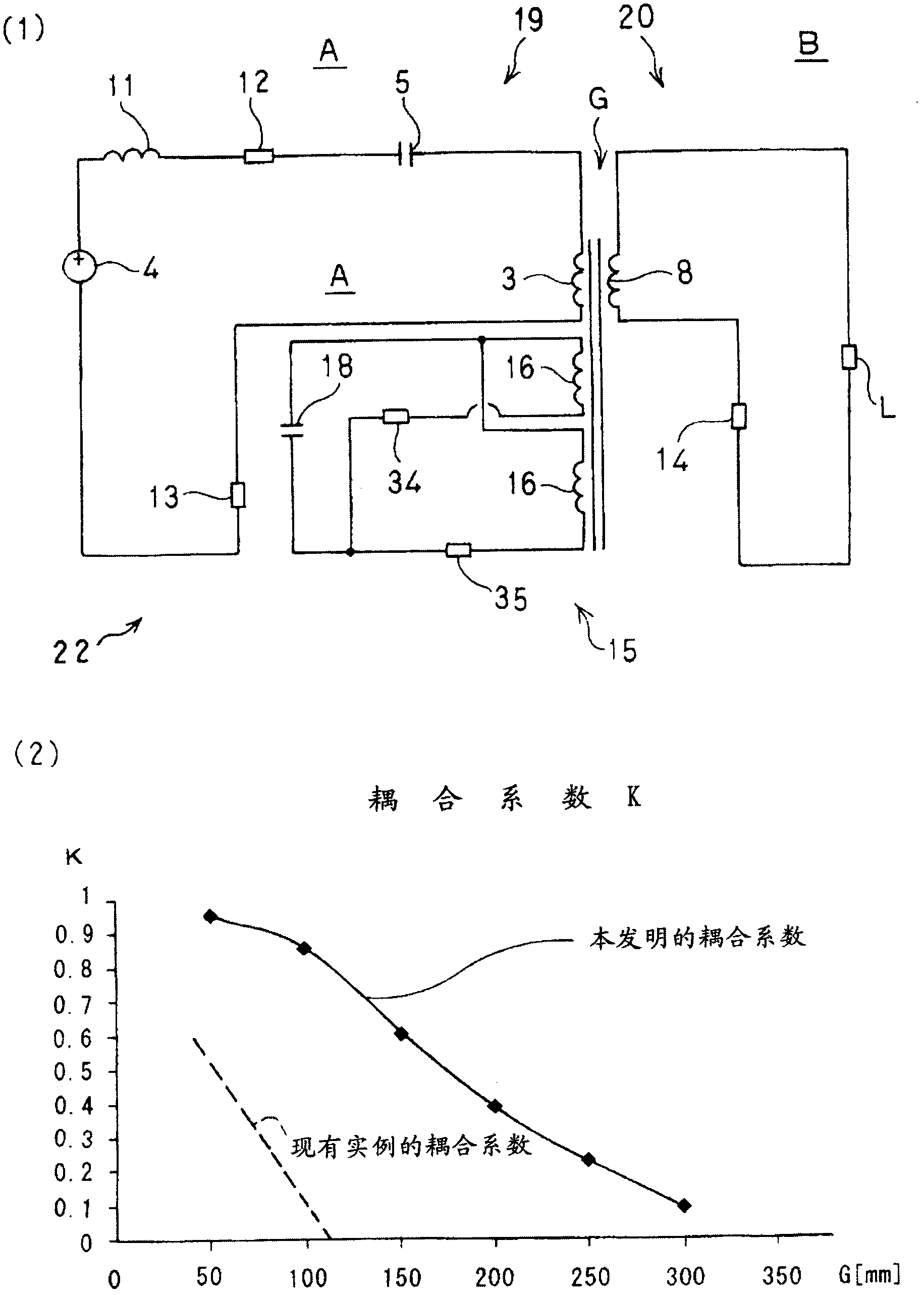

[0131] figure 2 (2) is for figure 2 (1) The embodiment of the non-contact power supply device 22 of the present invention shown and Figure 4 (1) Graphs of respective coupling coefficient data of the conventional example non-contact power supply apparatus 1 shown.

[0132] Comparing the experimental data with this graph also proves that the non-contact power supply device 22 of the present invention has a better coupling coefficient indicating the degree of electromagnetic coupling between the magnetic circuit coils than the conventional non-contact power supply device 1 . The experimental data is obtained by calculating the coupling coefficient K for each interval size based on actual measurement values while changing the interval size of the air gap G for the contactless power supply device 22 and the contactless power supply device 1 .

[0133] According to the obtained experimental data, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com