a heating wire

A heating wire and heating material technology, applied in the field of heating wire, can solve the problems of affecting oil flow, obstructing oil passage, oil height, etc., to achieve the effect of saving electric energy, ensuring heating effect, and reducing heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

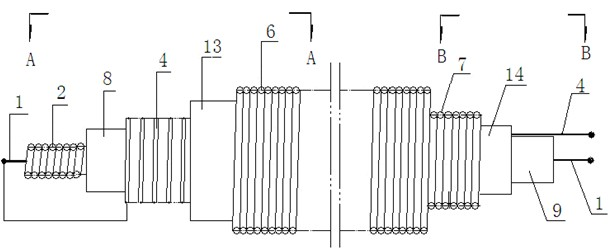

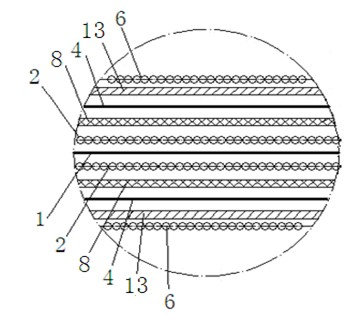

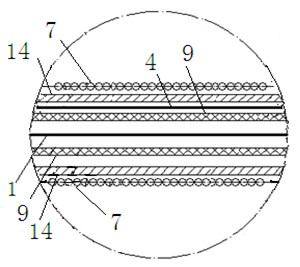

[0024] In the heating wire of this embodiment, the hollow of the first insulating layer 3 is wrapped with a loop line 1, and the outer layer of the first insulating layer 3 is wrapped with a coiled first heating material layer 4, and the first heating material layer 4 is connected with the loop line. The top of 1 is connected to form a loop, the outer layer of the first heating material layer 4 is covered with a second insulating layer 5, and the outer layer of the second insulating layer 5 is covered with a second protective spring, which is divided into a second protective spring. The thick section 6 of the dense spring is different from the thin section 7 of the second protective dense spring. The structure of the first heating material layer 4 corresponding to the package in the position of the thin section 7 of the second protective dense spring is linear. When in use, the second protective tight The thick spring section 6 is located inside the filter cup 11 to fully heat ...

Embodiment 2

[0033] A heating wire of this embodiment differs from Embodiment 1 in that

[0034] The part of the first insulating layer 3 inside the filter cup is equipped with a first protective spring 2 in its hollow, and the circuit line 1 passes through the middle of the first protective spring 2 .

[0035] Beneficial effect:

[0036] Since the first protective spring 2 is installed inside the first insulating layer 3 in the filter cup, the circuit line 1 has a certain space in the first insulating layer 3, which can disperse part of the heat of the circuit line, so that the first insulating layer 3 will not Accelerated aging due to high temperature; at the same time, it can ensure that the circuit line passes through the center of the first insulating layer 3, so the heating line is safer and less likely to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com