Inner high-pressure rubber pocket pipe fitting bending and forming device and forming method thereof

A rubber bag and internal high pressure technology, applied in the field of metal pressure processing, can solve the problems of uneven inner wall of the catheter, low strength, thinning of the outer wall of the catheter, etc., to eliminate inner wall wrinkles, high strength and rigidity, and good integrity of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

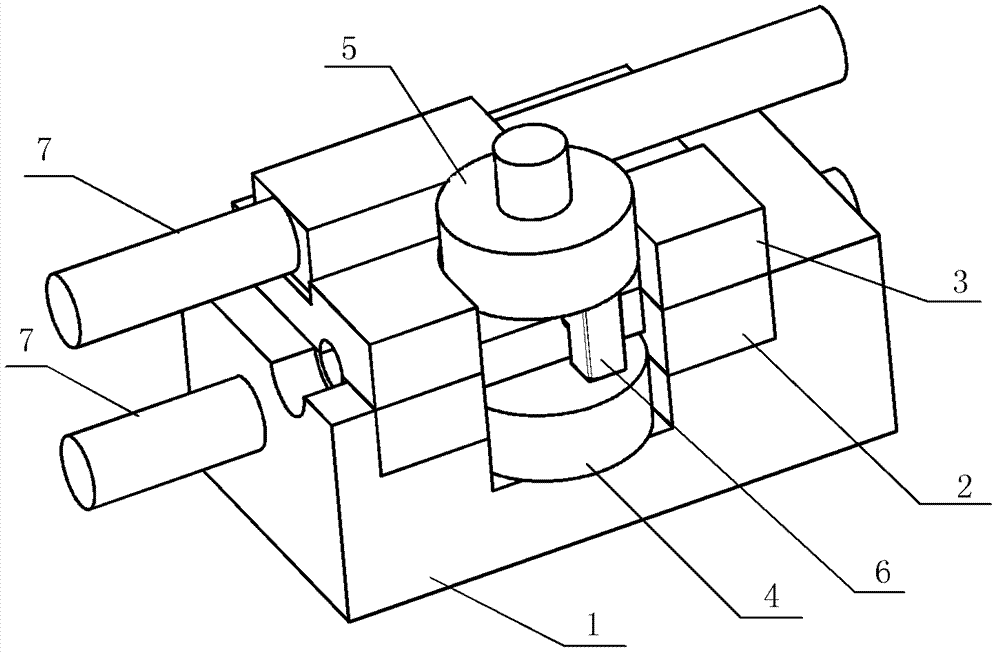

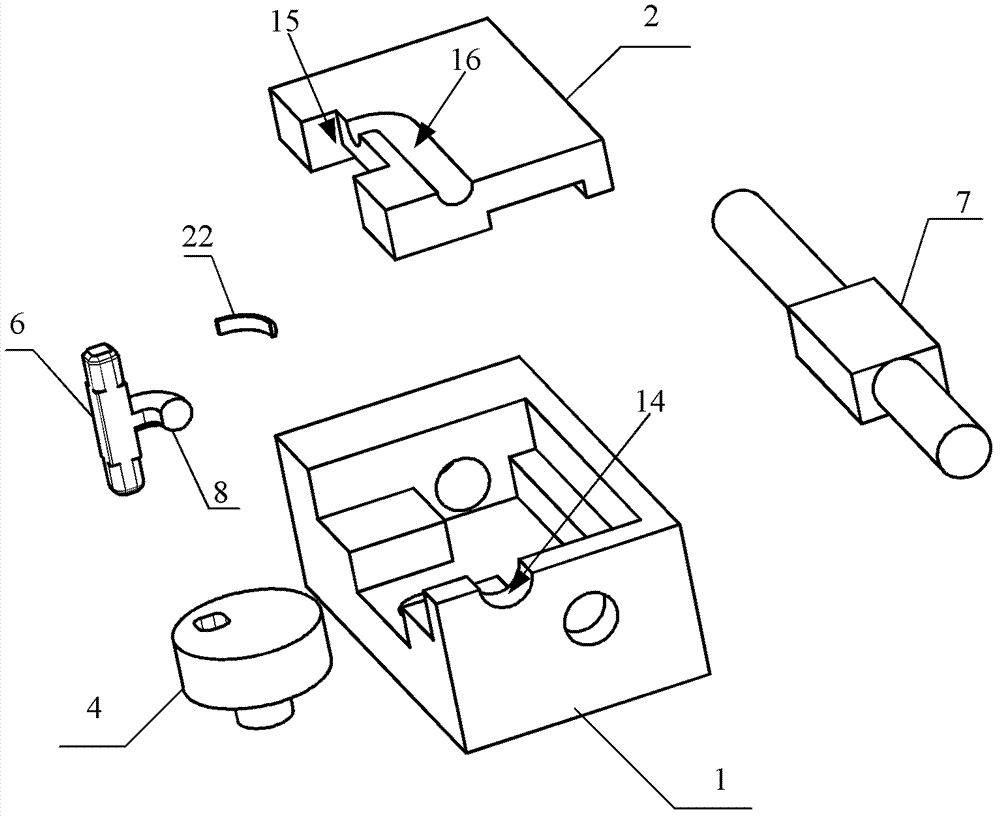

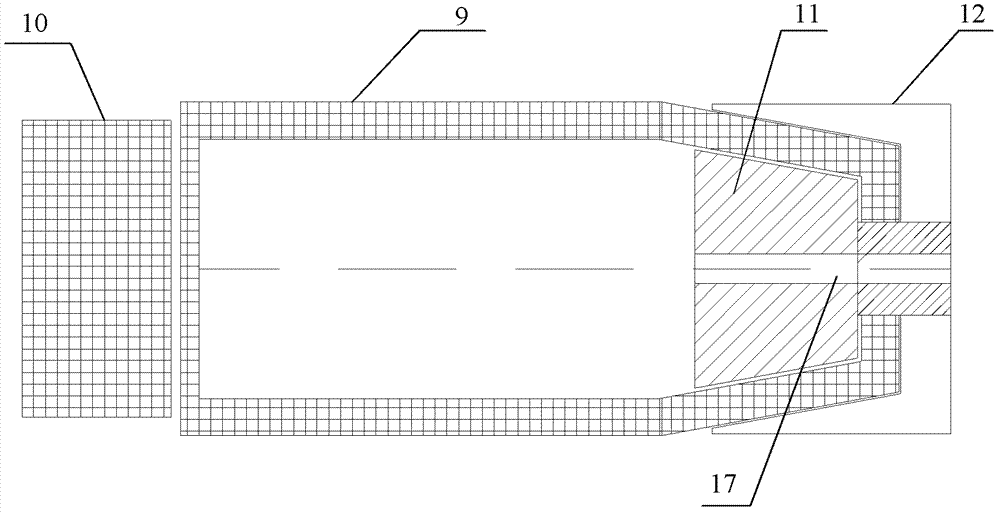

[0040] like figure 1 and figure 2As shown, the push-bending forming device of the inner high-pressure rubber bag tube of the present invention mainly includes: a mold frame 1, a lower mold 2, an upper mold 3, a lower gear 4, an upper gear 5, a rocker arm 6, a rack 7, and a bending push block 8 , Rubber bag 9, rubber pad 10, clamping bolt 11, clamping nut 12, and push rod 13.

[0041] like figure 2 As shown, the formwork 1 is a rectangular box structure with openings formed on the upper end and the front end, and a semicircular opening 14 is formed on the right side surface with the upper end recessed. Semicircular opening 14 also can be opened on the left side face top of formwork 1, as figure 1 As shown, whether to open on the upper side of the left side or the upper side of the right side can be set according to the needs of the user. The fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com