Fluid pressure forming method for small-radius elbow

A technology of fluid pressure and small radius, which is applied in the field of metal pressure processing, can solve the problems of low processing efficiency, inner wall wrinkling, uneven wall thickness, etc., and achieve the effect of improving welding quality, increasing the roundness of bend section, and simple sealing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

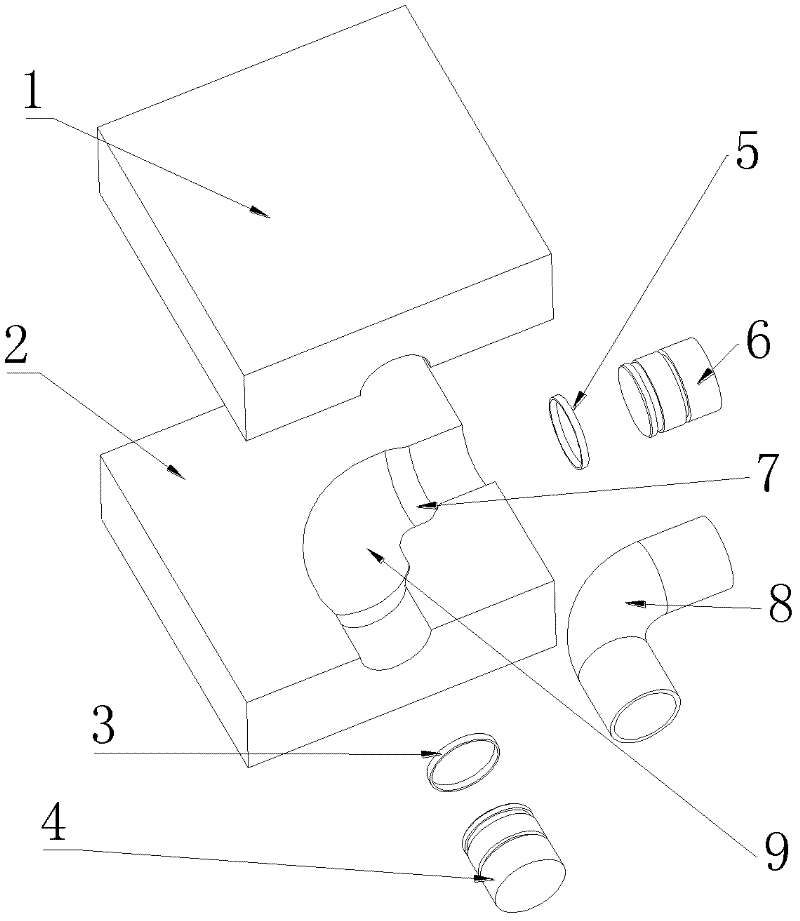

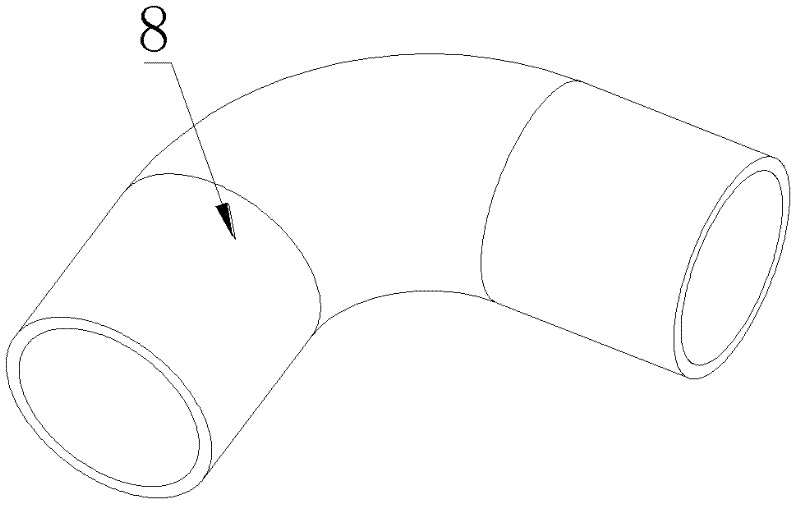

[0044] like figure 1 As shown, the device of the small-radius elbow fluid pressure forming method of the present invention includes: an upper mold 1, a lower mold 2, a lower sealing ring 3, a lower pushing head 4, an upper sealing ring 5, an upper pushing head 6, a transition section 7, Initial tube blank 8, half U-shaped groove 9.

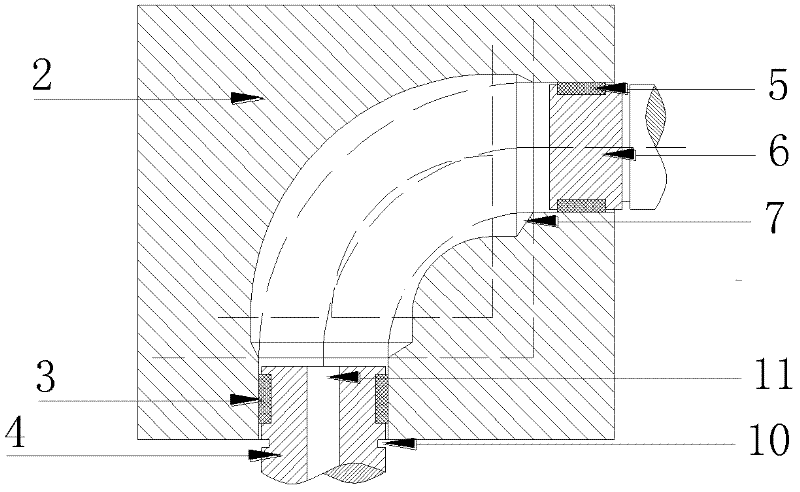

[0045] like figure 1 and as figure 2As shown, the lower mold 2 is arranged below the inside of the mold frame, and a half U-shaped groove 9 is formed in a depression on the surface of the lower mold 2 . The semi-U-shaped groove 9 size of upper die 1 and lower die 2 is the same after die closing. The longitudinal section of the half U-shaped groove 9 is semicircular, and the half U-shaped groove 9 is divided into an elbow part and a straight line part. The diameter of the elbow part is larger than that of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com