Inertia friction welding physical simulation test device

A friction welding and physical simulation technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of not being able to respond to the temperature of the weld zone in real time, hindering the real-time monitoring of infrared thermometers, and being unable to observe the temperature field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

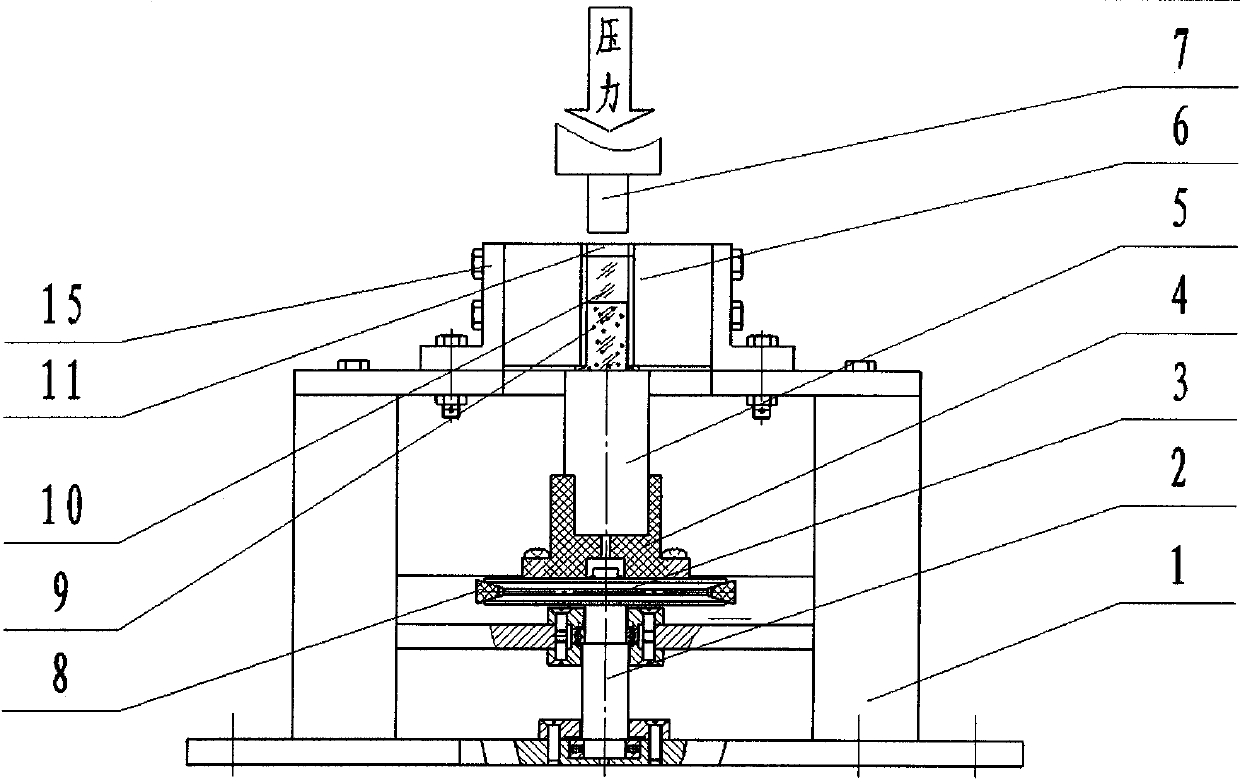

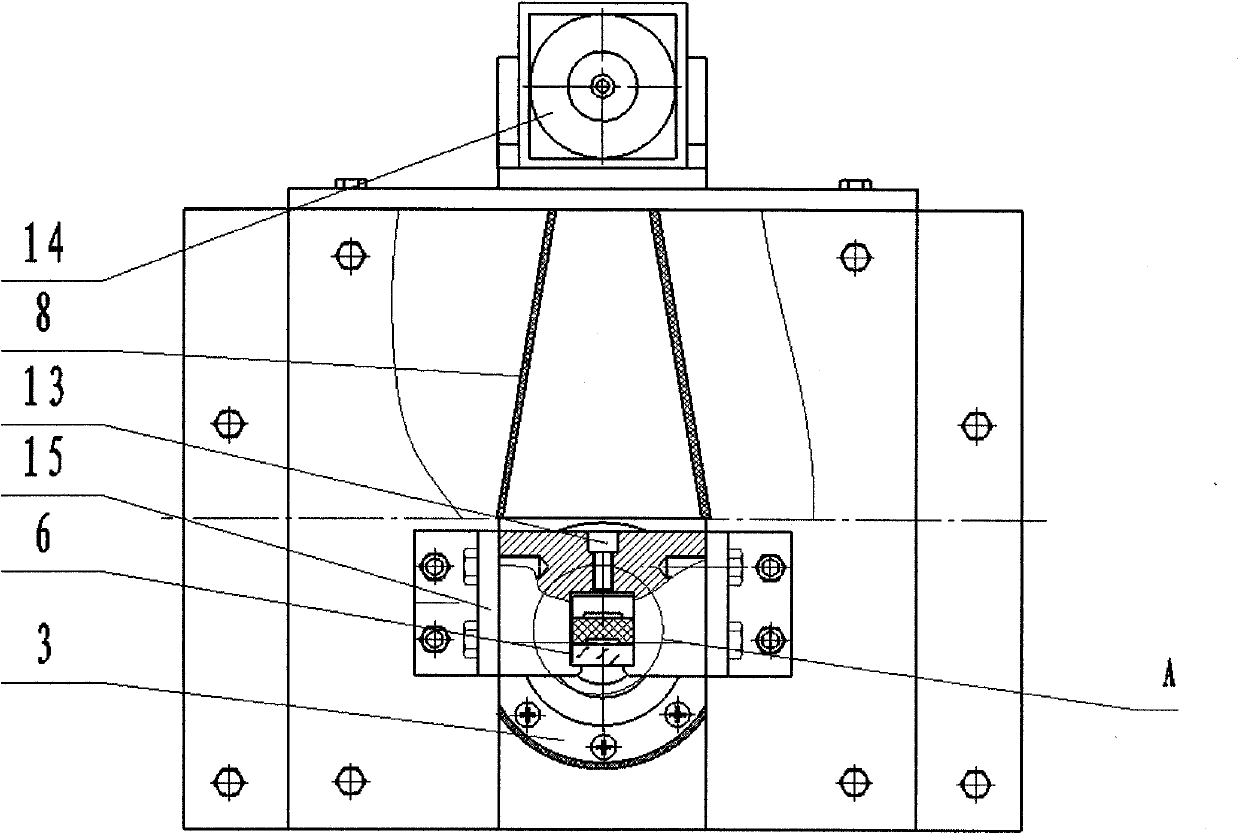

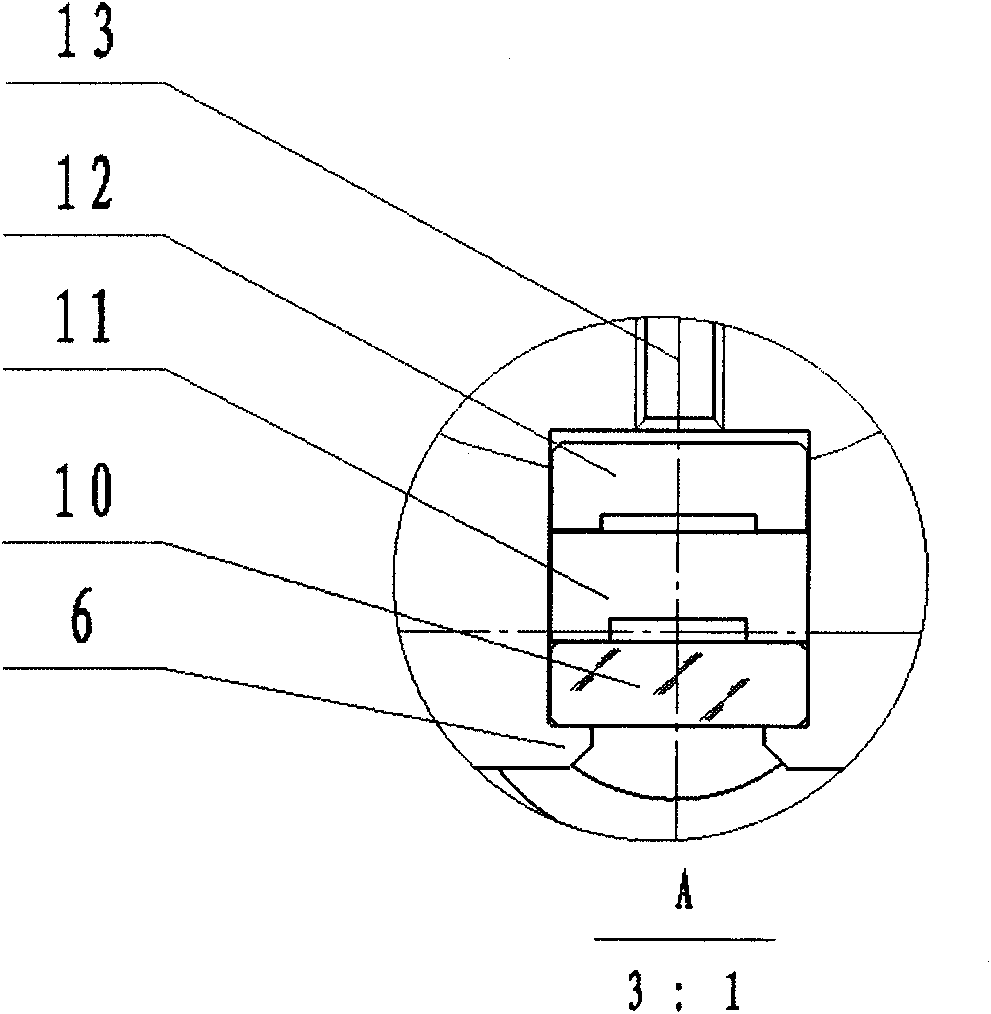

[0015] Refer to attached figure 1 , the inertial friction welding physical simulation experiment device includes a base 1, a shaft 2, a belt pulley 3, a bracket 4, a heating body 5, a fixed block 6, a pressure head 7, a belt 8, a test piece 9, an infrared transparent material 10, and a bakelite groove 11. Adjusting plate 12, adjusting nut 13, driving motor 14, L-shaped bracket 15. The shaft 2 is installed on the lower part of the base 1 through bearings, the belt pulley 3 is fixed on the top of the shaft 2 by pins, the bracket 4 is fixed on the belt pulley 3 by screws, the heating body 5 is installed on the bracket 4, and the heating body 5 The upper end is close to the lower end of the fixed block 6; one side of the fixed block 6 is provided with a T-shaped groove, and the fixed block 6 is fixed on the top of the base by an L-shaped bracket 15; the infrared mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com