Automatic control transfer printing device

A technology of transfer printing and blanket tape, applied in transfer printing, rotary printing machine, printing, etc., to achieve the effect of good output quality, convenient operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

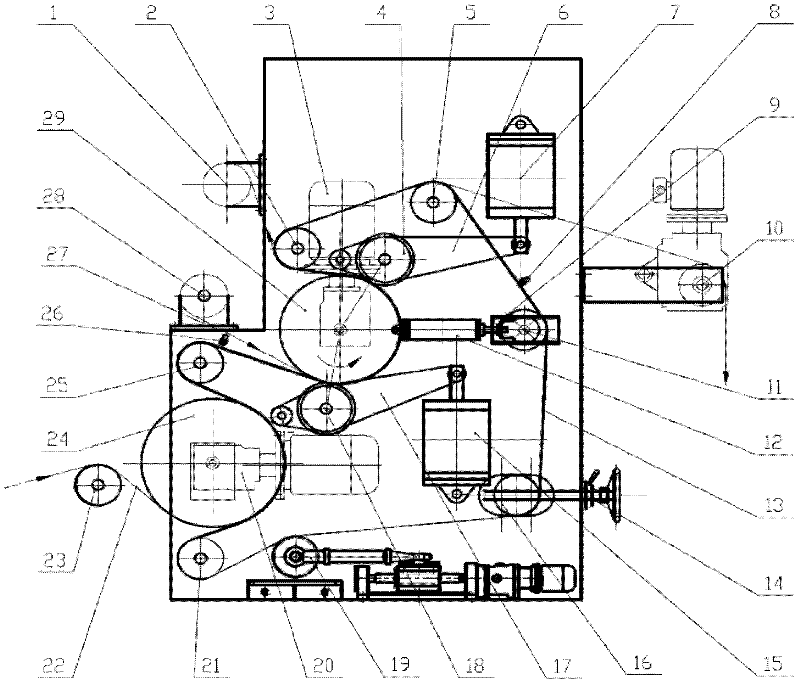

[0029] figure 1 A schematic structural view of Embodiment 1 of an automatic control type transfer printing device is shown.

[0030] The automatic control type transfer printing device of embodiment 1 includes left and right frames, main roller, heating roller, endless blanket belt, support guide roller, adjustment guide roller, tension guide roller, uniform pressure roller, correction guide roller and accessory parts. figure 1 Only one side of the rack is shown. On the left and right frames, a main roller 29 and a heating roller 24 are fixedly connected by bearings and bearing seats (not shown), and eight various guide rollers that play the role of supporting rollers are connected by bearings and bearing seats; The blanket belt 13 is wrapped around the eight supporting rollers and kept in contact with the main roller and the heating roller through the eight supporting rollers, and there is a deflection guide roller in contact with the outer peripheral surface of the endless ...

Embodiment 2

[0043] The automatic control transfer printing device in Embodiment 2 is basically the same as the automatic control transfer printing device in Embodiment 1, and this embodiment only describes the different parts.

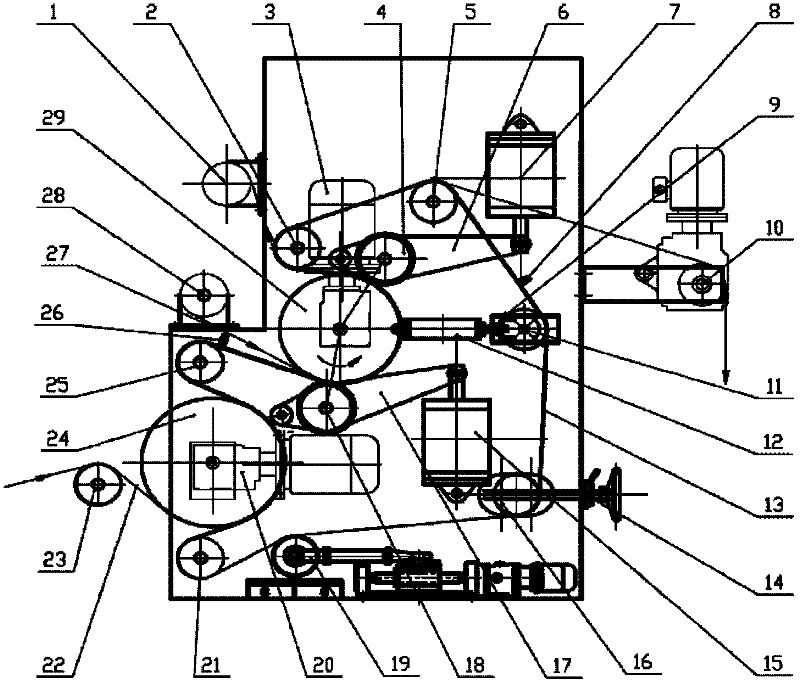

[0044] The first uniform pressure roller 18 contacts the entrance contact pressure line of the main roller 29 via the blanket belt and is located at the counterclockwise direction of the entrance tangent of the main roller 29. The second uniform pressure roller 4 is connected to the main roller through the blanket belt. The contact pressure line at the exit of 29 contacts is at the place where the main roller 29 exit tangent rotates 40° in the clockwise direction, and the ring-shaped blanket belt occupies 5 / 18 of the main roller circumference between the two uniform pressure roller inlet and outlet contact pressure lines. noodle.

[0045] The pressure device of tension guide roller 11 and uniform pressure roller 4 and 18 adopts hydraulic pressure device, so that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com