Check valve with safety valve

A check valve and safety valve technology, applied in the field of check valve with safety valve, can solve the problems of lifting, affecting the arrangement of other pipe fittings, difficulty in implementation, etc., and achieve the effect of not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

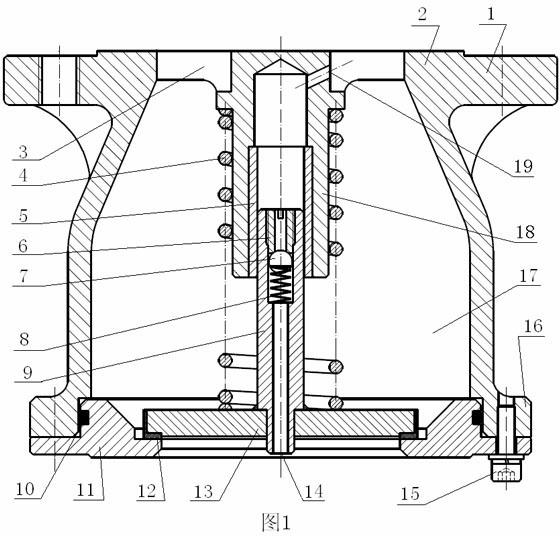

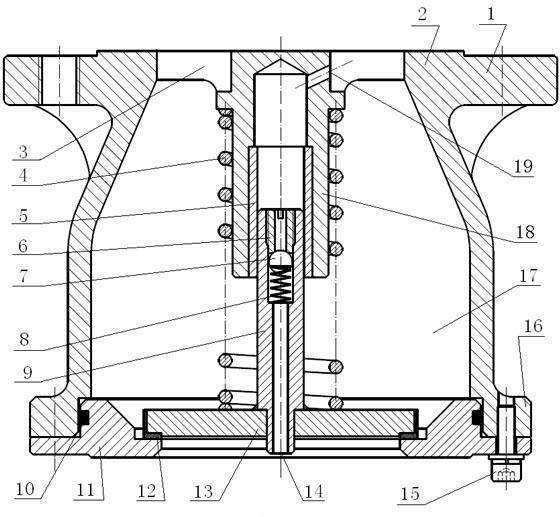

[0012] figure 1 Among them, the check valve with a safety valve has a check valve body 2 with an outflow end flange 1, an inflow end flange 16 and a check valve core 18, and the outflow end flange 1 is connected with the suction pipe of an oil pump, etc. by bolts. The downstream pipe fittings are connected, the check valve seat 11 is fixed on the inflow end flange 16 by bolts 15, and the inflow end flange seal 10 seals the check valve body 2 and the check valve seat 11. The check valve core 18 in the center of the check valve body 2 is inlaid with the valve stem sleeve 4, the valve disc 13 is connected with the valve stem 9, and moves as the valve stem 9 slides in the valve stem sleeve 5, the valve disc 13 Slide along the center line of the valve body 2 to complete the opening and closing action.

[0013] Inside the valve stem 9 of the check valve, a safety valve consisting of a safety valve seat 6, a steel ball 7 and a safety valve spring 8 is installed. The safety valve pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com