Supporting wheel device for the furnace tank of the tilting drum type resistance rotary furnace

A rotary kiln and drum-type technology is applied in the field of furnace support roller devices of a tiltable drum resistance rotary furnace, which can solve the problems of short service life, poor furnace support roller safety, easy damage to contact surfaces and slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

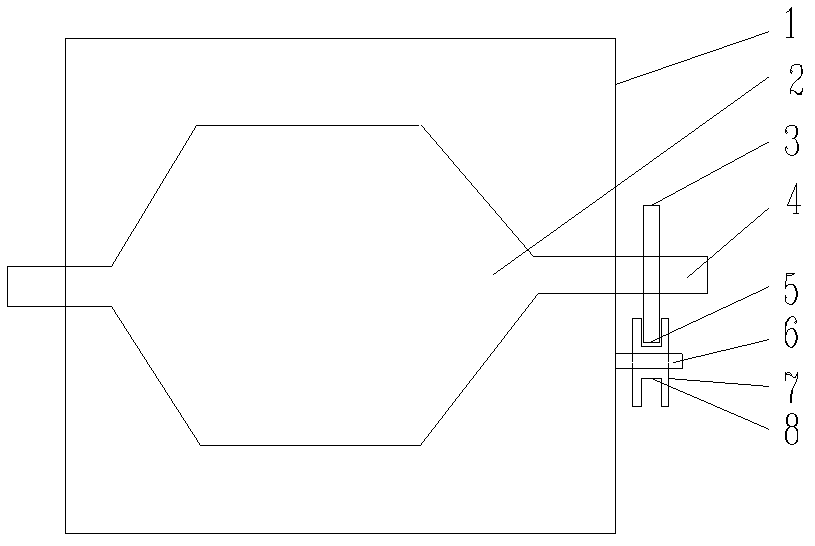

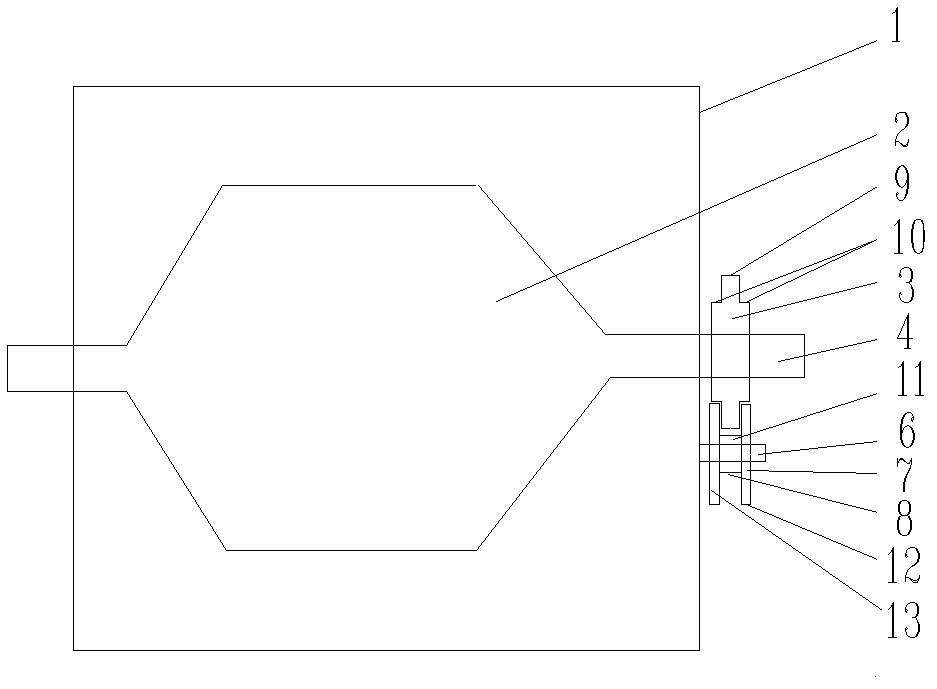

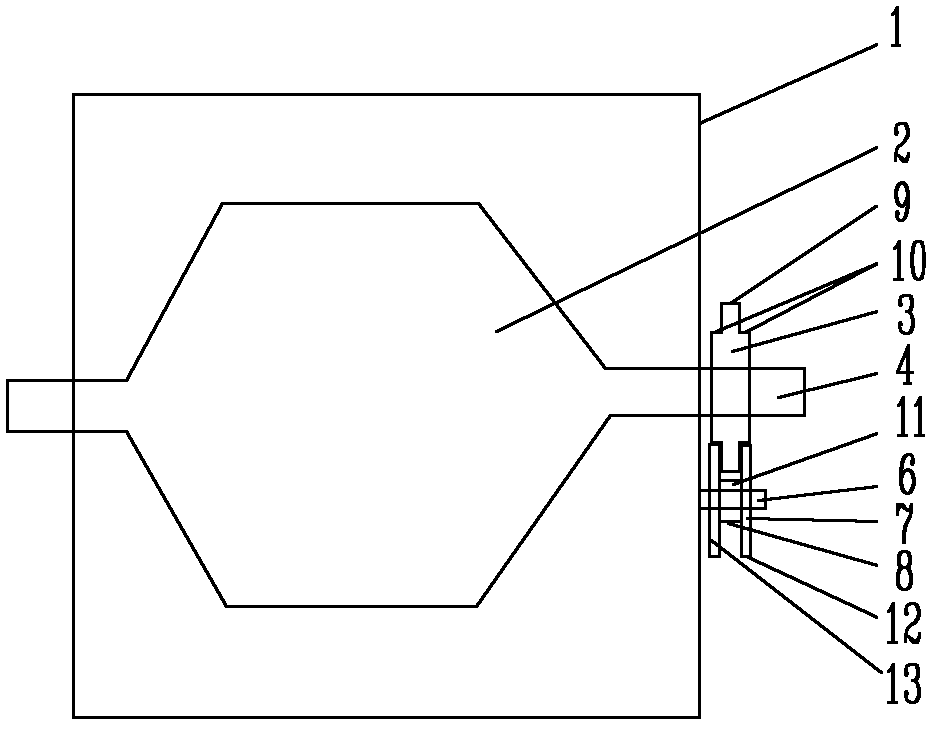

[0013] like figure 2 Shown: a tilting drum-type resistance rotary furnace furnace furnace supporting wheel device. Furnace receptacle tray 3 is housed on furnace revolving shaft 4, and furnace receptacle tray 3 is supported by supporting wheel 6, and supporting wheel 6 is sleeved on the bearing shaft 7, and bearing shaft 7 is fixedly installed on the rotary furnace shell 1. Its characteristics are: the center of the furnace tray 3 is a tray flange 10, and the two sides of the furnace tray 3 are indented tray support edges 11. Supporting wheel 6 is made of two bearings B14 and a washer 12 with a diameter all smaller than two bearings B14 sandwiched in the middle of two bearings B14. The pallet flange 10 in the middle of the furnace pallet 3 is movable between two bearings B14, and the thickness of its pallet flange 10 is slightly less than the thickness of the washer 12, and the pallet flange 10 does not contact with both sides bearings B14 and the middle washer 12. The bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com