led backlight drive circuit

A technology of backlight drive circuit and boost circuit, which is applied in the direction of light source, electric light source, electrical components, etc., can solve the problems of increasing cost, and achieve the effects of improving boost efficiency, good practicability, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

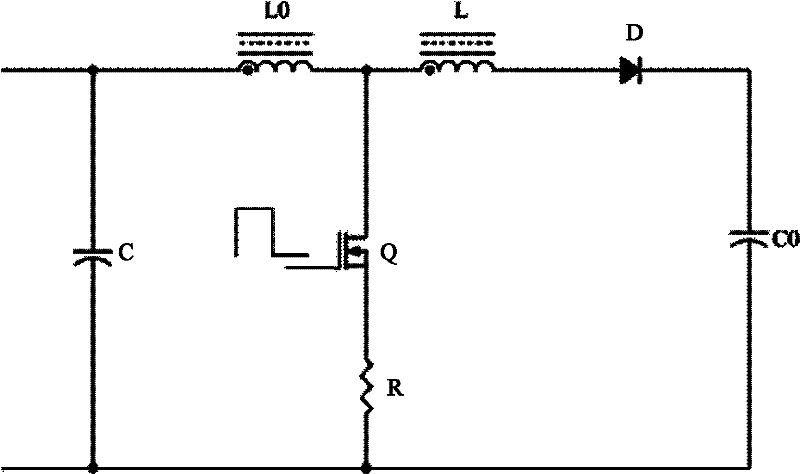

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

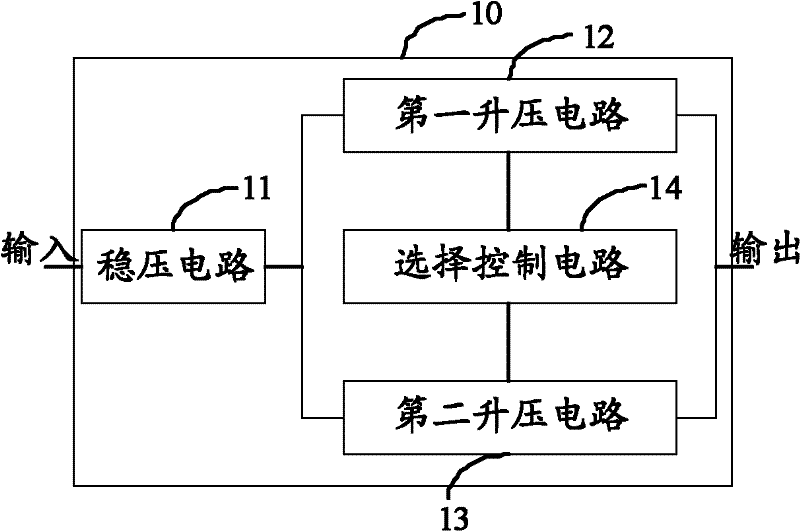

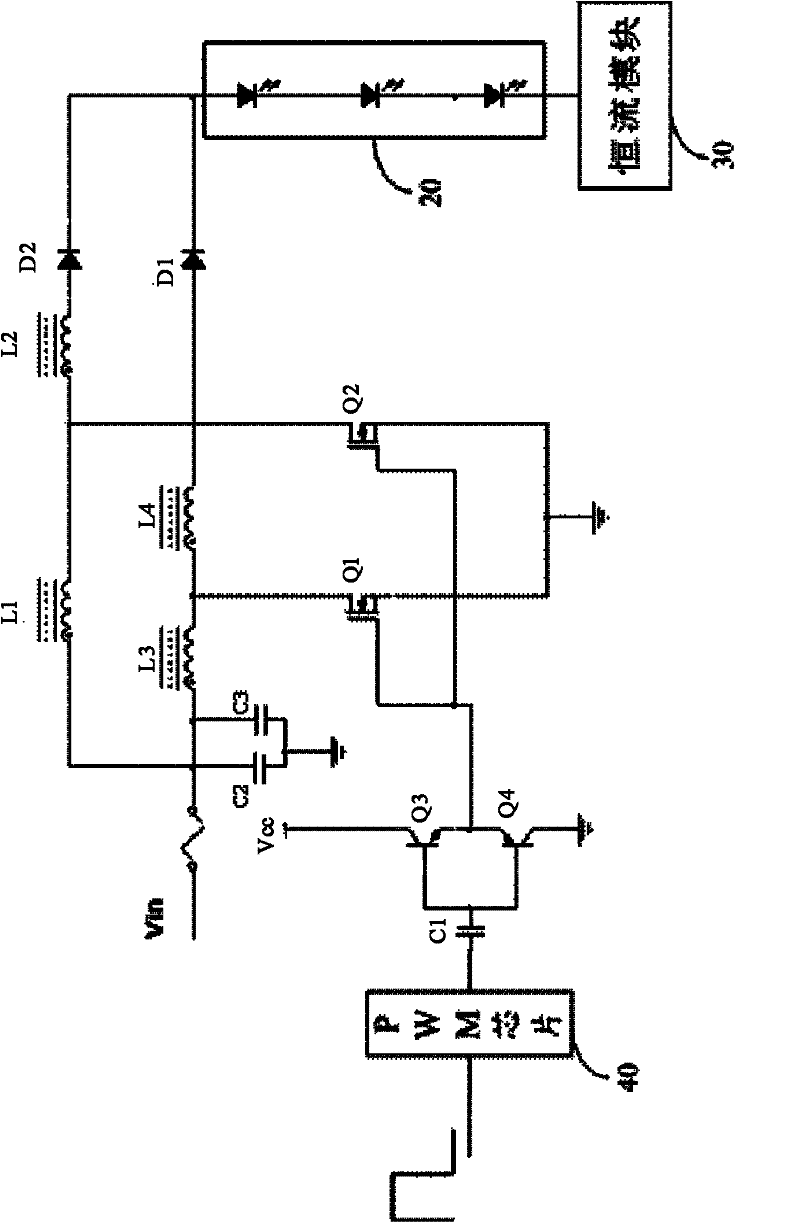

[0031] refer to figure 2 , the present invention proposes an embodiment of an LED backlight driving circuit 10 . The LED backlight driving circuit 10 supplies power for the LED backlight module (not shown), and it includes: a voltage stabilizing circuit 11, a first voltage boosting circuit 12, a second voltage boosting circuit 13 and a selection control circuit 14; the voltage stabilizing circuit 11. Receive an input voltage, filter the input voltage, and output a regulated DC power; the first boost circuit 12 receives the regulated DC power, boosts it and outputs it to the LED backlight module; the second boost circuit The circuit 13 receives the regulated direct current, boosts it and outputs it to the LED backlight module; the selection control circuit 14 alternately selects the first boost circuit 12 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com