Heat dispersion structure and method of thin film capacitor

A technology of thin film capacitors and heat dissipation structures, which is applied in the direction of thin film/thick film capacitors, laminated capacitors, fixed capacitor parts, etc., can solve the problems that capacitors cannot bear heat and the life of capacitors is shortened, so as to solve heat dissipation problems and reduce heat dissipation. resistance, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

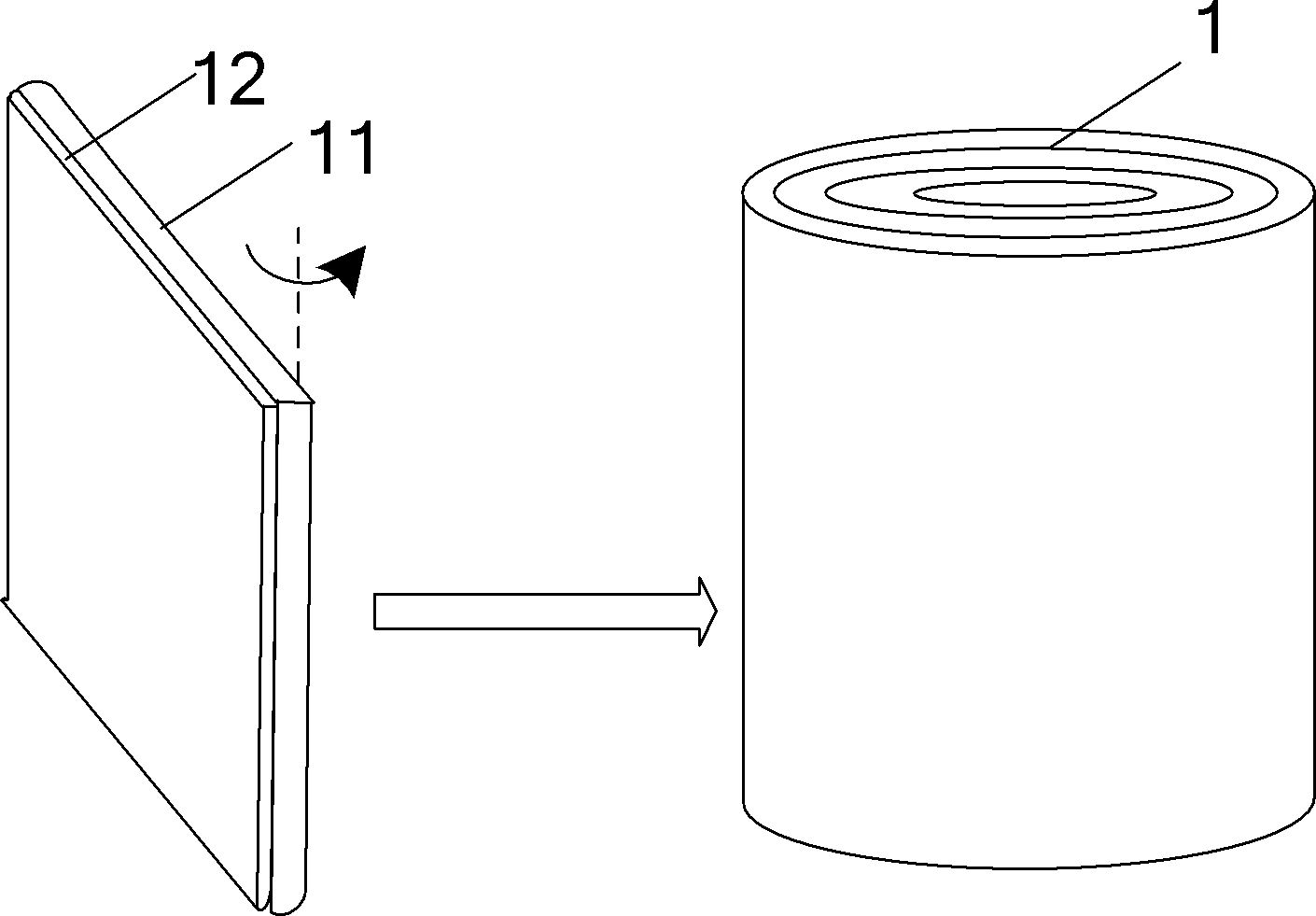

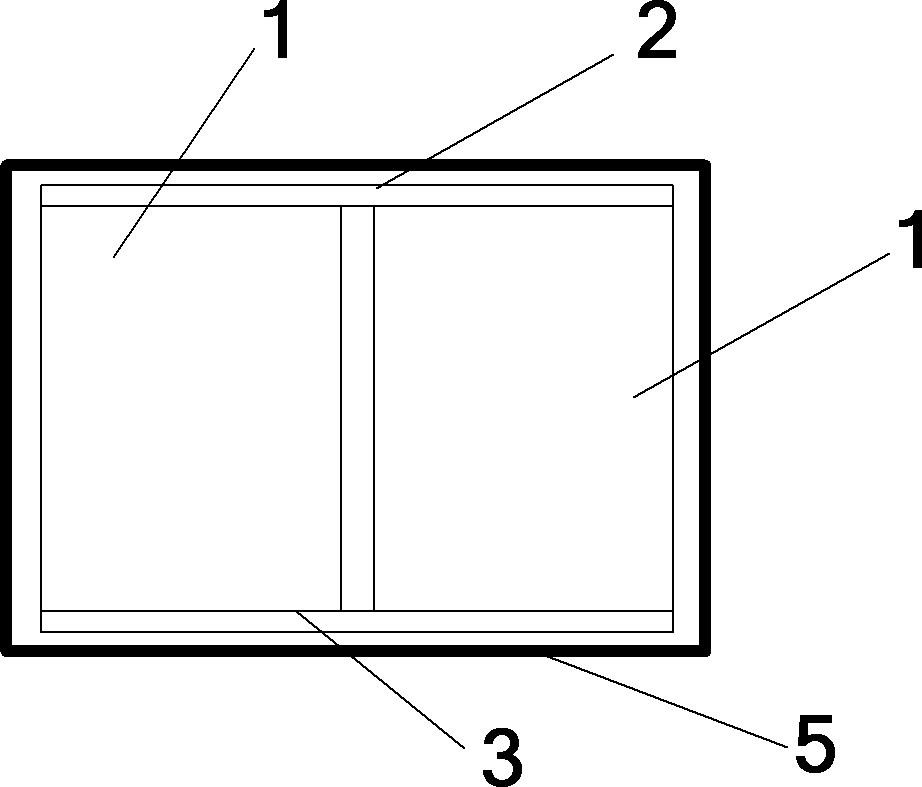

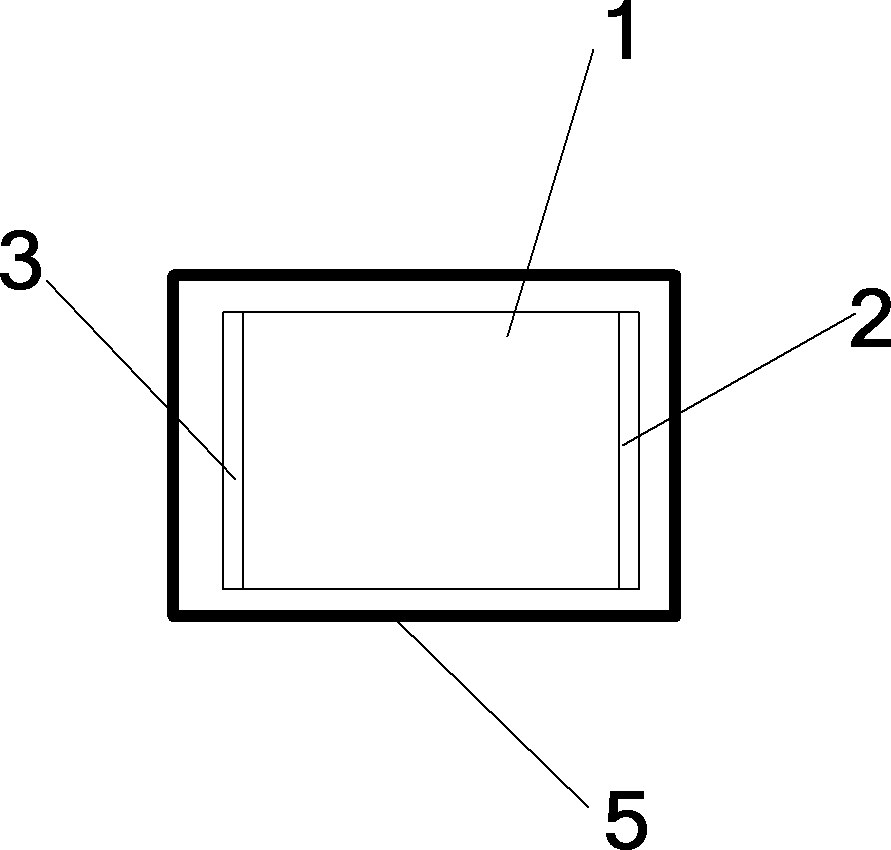

[0031] In the heat dissipation structure of the film capacitor of the present invention, the film capacitor includes a film core 1, positive and negative busbars 2, 3 connected to the end face of the film core 1, the busbars extend to contact with the cooling plate, and Insulating paper is arranged between the busbar and the cooling plate.

[0032] The first embodiment provided by the present invention, such as Figure 4a , 4b As shown, the film core 1 and the busbars 2 and 3 are arranged in a plastic casing 5 with an open bottom, and the plastic casing 5 is fixed on a water cooling plate 6 .

[0033] Such as Figure 4a As shown, the film core 1 is in a vertical state, with a negative busbar 3 connected to its upper end and a positive busbar 2 connected to its lower end. In this embodiment, the bottom surface of the plastic shell 5 and the potting compound on the bottom surface are removed, so the positive busbar 2 is directly in contact with the water cooling plate 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com