Wire protection tubes for equipment used in the wet process of printed circuit boards

A printed circuit board and wet process technology, applied in the field of protective casing, can solve the problems of wires being easily corroded, not sealed, and not well protected, so as to avoid electrical failures and safety accidents, and is easy to implement , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

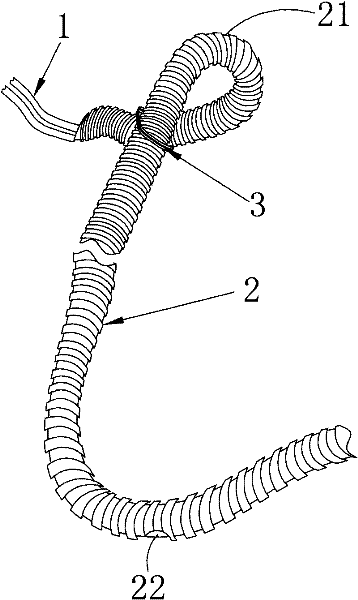

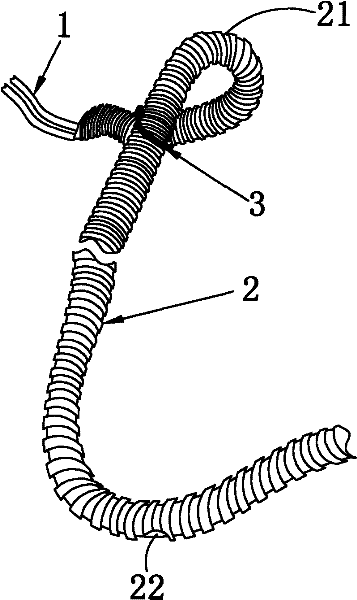

[0014] Embodiment: A wire protection tube for equipment used in the wet process of printed circuit boards. A protective tube 2 is sheathed outside the wire 1 of the equipment used in the wet process of printed circuit boards. The initial section 21 of the protective tube is curved upwards, so that It can effectively prevent liquid from entering the protective tube.

[0015] The lowest part of the whole protective pipe is provided with water outlet hole 22, even if there is hydrops in the protective pipe like this, also can discharge from water outlet hole, can not cause electrical failure and safety accident.

[0016] The protective pipe is a corrugated pipe.

[0017] The initial pipe section of the corrugated pipe is bound with a cable tie 3 to keep the initial pipe section of the corrugated pipe in a curved shape.

[0018] The wires of the equipment used in the printed circuit board wet process may be the power cord of the liquid level switch on the printed circuit board we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com