Installation method for forging machine motor rotor and photoelectric sensor

A photoelectric sensor and motor rotor technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as eccentricity and control failure of circular grating sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

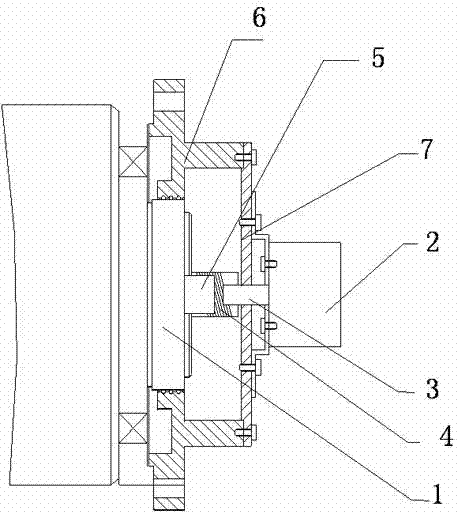

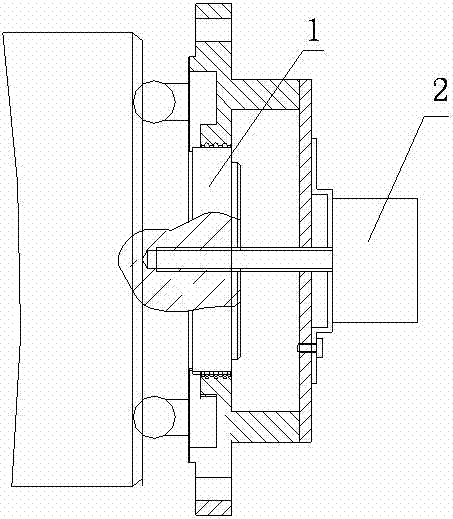

[0013] Such as figure 1 and figure 2 As shown, a method for installing a motor rotor and a photoelectric sensor of a forging machine tool includes a motor and a circular grating sensor 2 arranged on the motor rotor for transmitting control signals, and the outer end of the rotor main shaft 1 is circumferentially arranged There are bearings and a bearing cover 6, and the bearing cover 6 has a screw hole that is fixed with the sensor bridge 7, and the circular grating sensor 2 is fixed at the center opening of the sensor bridge, and the circular grating sensor 2 passes through the sensor bridge 7 and the bearing cover. 6 is fixed, the rotor pin shaft 5 protrudes concentrically from the rotor main shaft 1, and the circular grating sensor 2 extends inwards from the sensor shaft 3, and the interfering connector 4 transitions between the rotor pin shaft 5 and the sensor shaft 3 , so that the circular grating sensor 2 is electrically connected with the motor rotor.

[0014] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com