The installation structure of the connection terminal of the photovoltaic junction box

A technology for connecting terminals and volt junction boxes, applied in the field of photovoltaic power generation, which can solve problems affecting device performance, insufficient heat resistance, and rising production costs, and achieve the effects of improving reliability, reducing temperature, and facilitating cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The present invention is composed of the following parts: connecting terminal assembly, diode, mounting plate, photovoltaic junction box base.

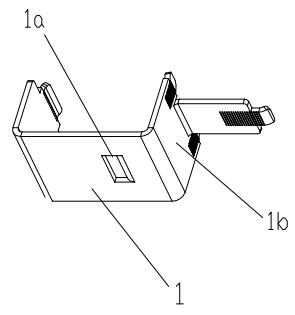

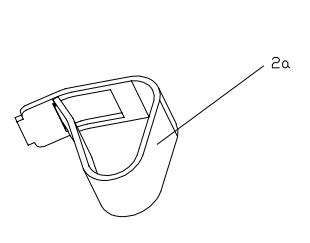

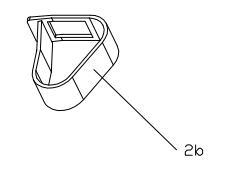

[0026] First, the connection terminal assembly is introduced, which includes a terminal body 1 , a wire clip 2 a , a bus strip clip 2 c , two diode clips 2 b and a heat dissipation support 3 . Such as figure 1 As shown, the terminal main body 1 is composed of several end surfaces connected vertically to each other. Such as figure 2 , image 3 , Figure 4 As shown, the wire clip 2a, the diode clip 2b and the bus clip 2c all adopt a cage structure. Image 6 The structure of the heat dissipation support is shown.

[0027] The assembly relationship of the terminal body 1, the wire clamp 2a, the bus strip clamp 2c and the diode clamp 2b is as follows: Figure 5 As shown, the terminal body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com