piston motor

A motor, piston type technology, applied in the direction of generator/motor, electrical components, etc., can solve the problems of inconvenient promotion, high cost, complex structure, etc., and achieve the effects of simple structure, high work efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

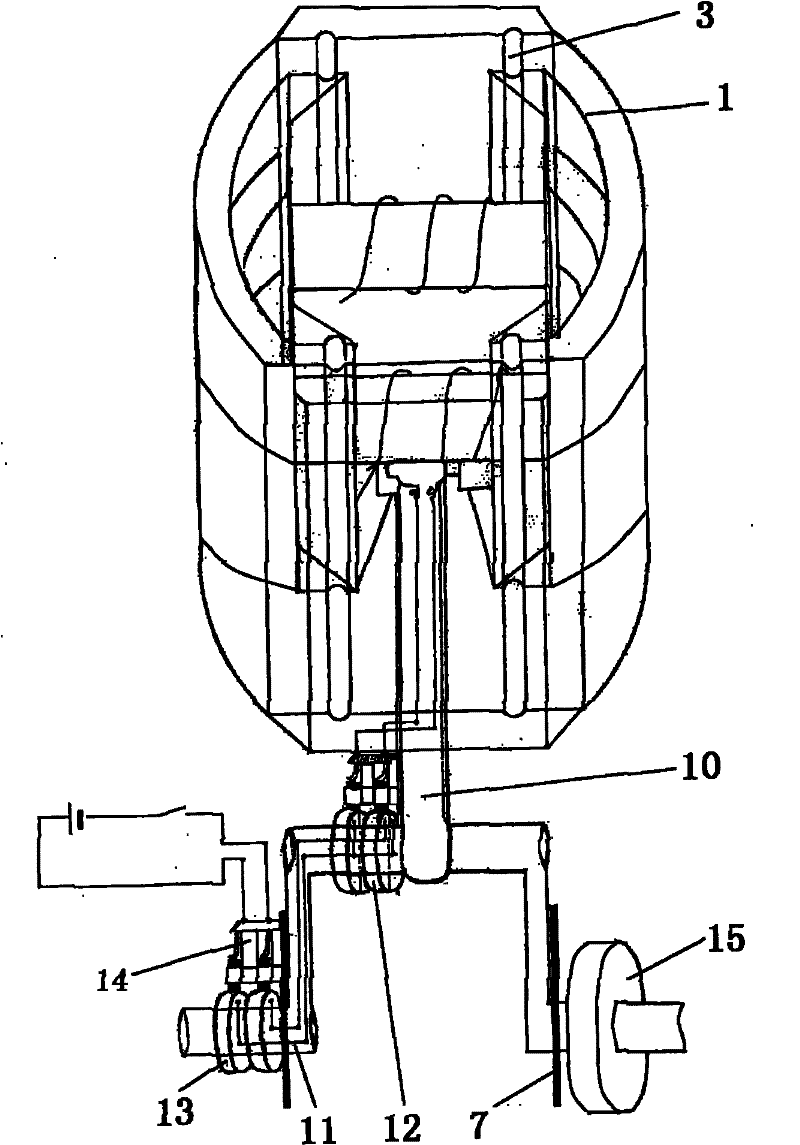

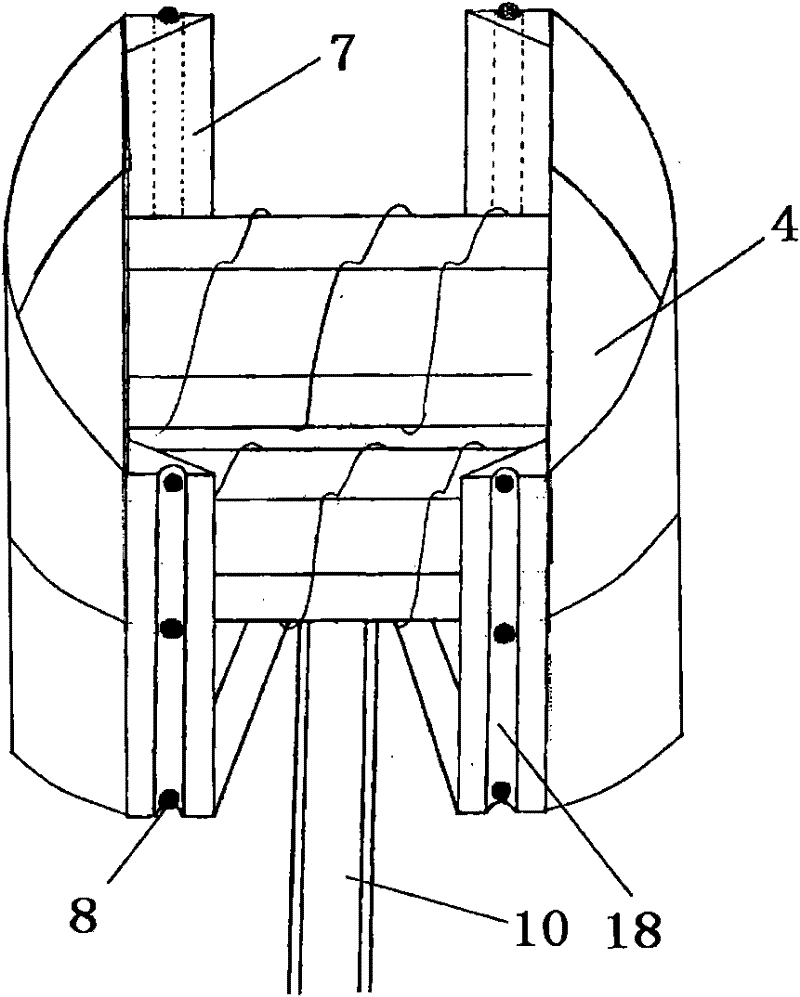

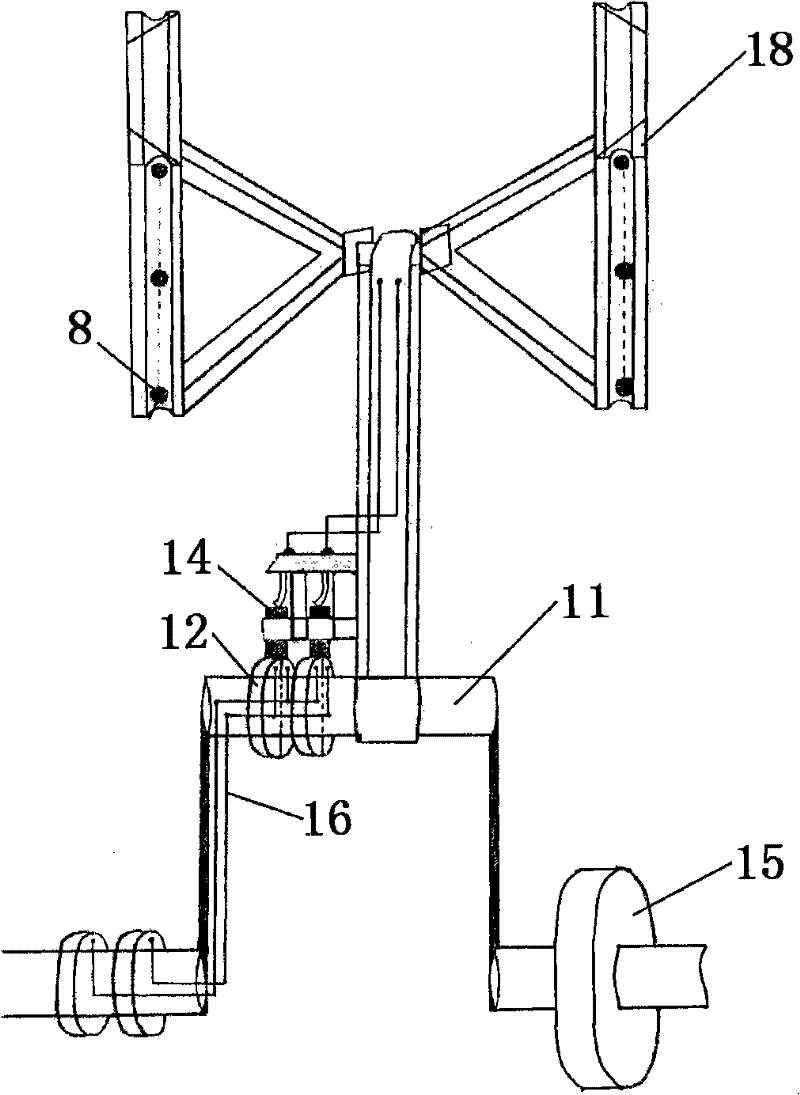

[0036] A piston motor such as Figure 1~3 Shown, comprise frame 17, be contained in the crank linkage mechanism 9 that is made up of connecting rod 10, crankshaft 11 and flywheel 15 on piston fixed frame 7, the piston 4 that links to each other with connecting rod 10 tops, described piston 4 is made up of two pieces It is composed of 5 superimposed electromagnets, and the magnetic poles of two adjacent superimposed electromagnets are staggered, that is, in the initial state, the left side of the lower electromagnet is N pole, named N4, the right side is S pole, named S5, the upper layer The left side of the electromagnet is the S pole, which is named S4, and the right side is the N pole, which is named N5. The outer periphery of the piston 4 is provided with a booster arm 1, and the booster arm 1 formed by superimposing three groups of permanent magnets 2 arranged in a staggered manner has a cavity for accommodating the piston 4 to slide up and down relative to the booster arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com