Electric blanket multifunctional automatic wiring machine

A multi-functional, electric blanket technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of many factors involved in manual participation, the inability to realize automatic wiring, and the inability to fully realize automation, etc., to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

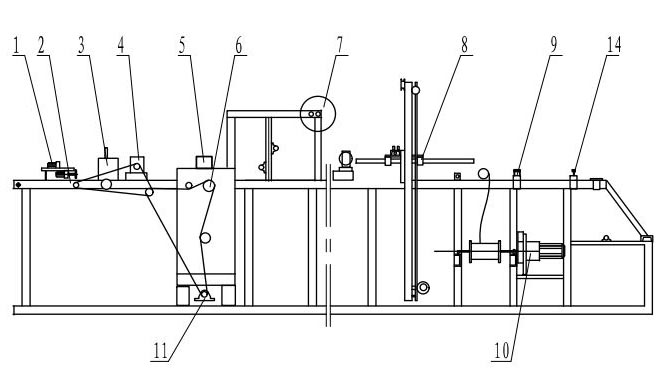

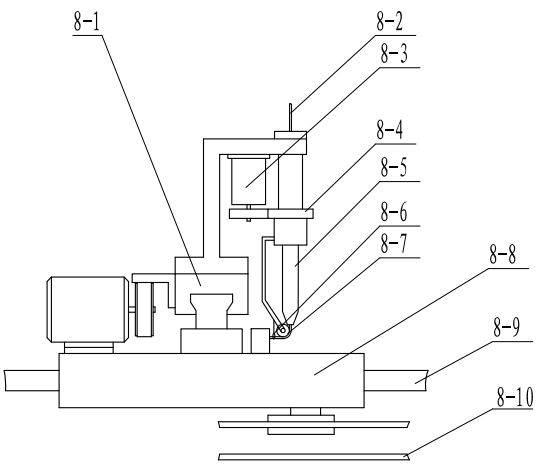

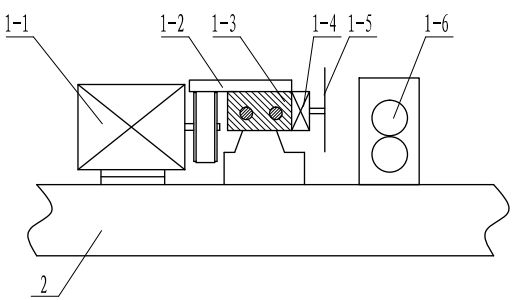

[0028] According to attached figure 1 And attached Figure 7 As shown, the present invention specifically relates to a multifunctional automatic wiring machine for electric blankets, including a frame 2, and a feeding device driven by a feeding motor 3 to rotate the chain, and the chain is arranged with thread-hanging needles at intervals The plate 14 is characterized in that the front section of the frame 2 is provided with a puncture needle hanging device 14 and a wiring device 8, the middle section of the frame 2 is provided with a heat-sealing mechanism, and the wiring device 8 is provided with an automatic disconnection mechanism 13. The thread breaking mechanism 13 includes a main cylinder 13-1 fixed on the wiring device 8, the piston rod end of the main cylinder 13-1 is fixed with the side wall of the cutting cylinder 13-2, and the piston of the cutting cylinder 13-2 The rod end is fixed with cutter 13-3, and the cylinder body of cutting cylinder 13-2 is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com