Cutting edge positioning type welding structure and method for preventing pin offset

A welding structure, positioning technology, applied in the direction of printed circuits, electrical components, electrical components connected with non-printed electrical components, can solve problems such as reducing process efficiency, problems, increasing manufacturing costs, etc., to improve process efficiency, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

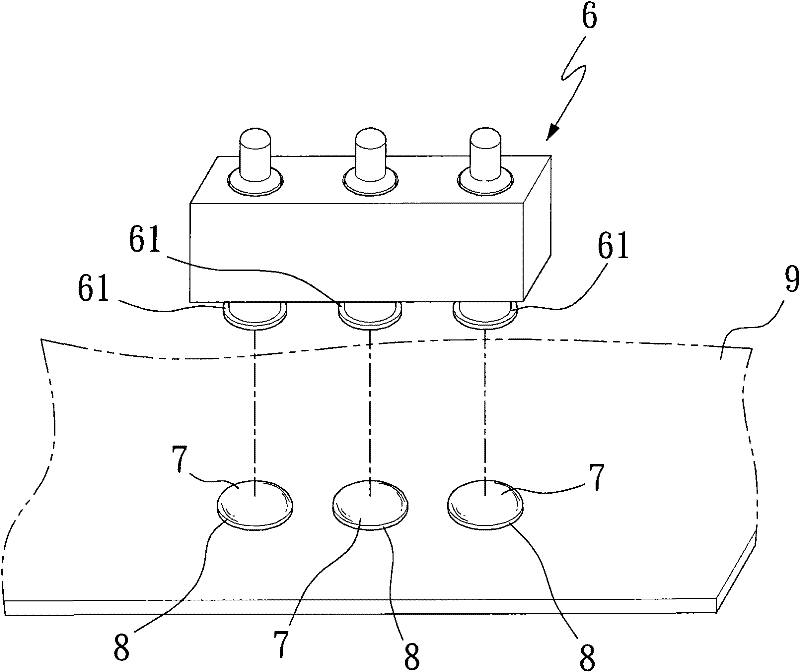

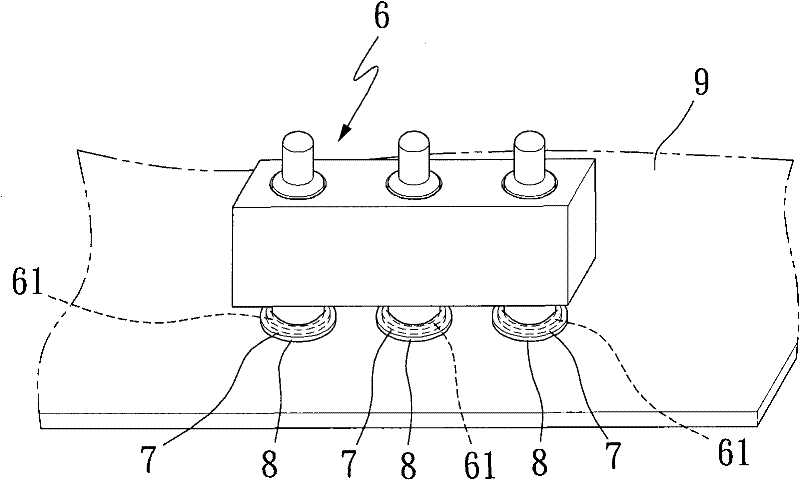

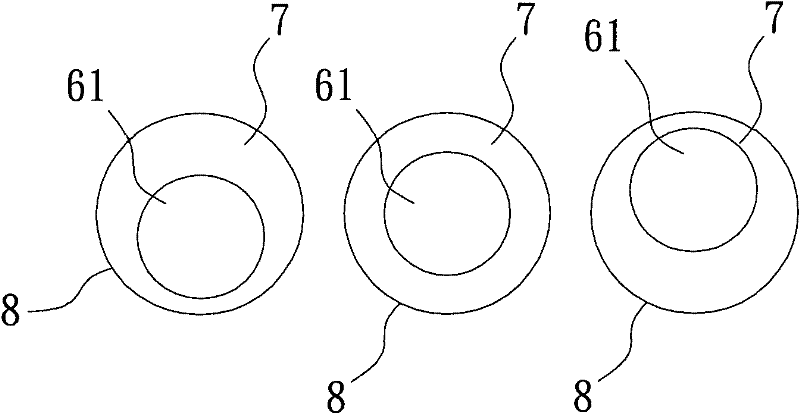

[0035] Figure 4 to Figure 6 They are respectively an exploded view, an assembled view and a top view of pins, solder and welding pads of a preferred embodiment of the present invention. As shown in the figure, the first aspect of the present invention is a trimming positioning type welding structure, including A welding pad 3 provided on the circuit board 5 is used to join the SMT electronic assembly 1 with a plurality of pins 11, the size of the welding pad 3 is larger than the pins 11, and the shape of the above-mentioned pins 11 can be circular and The number can be two or more. In the drawings, three pins 11 are taken as an example. The number of the above-mentioned welding pads 3 corresponds to the number of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com