Method for improving color and luster of deep-fried products and deep-fried products

A product and color technology, applied in the field of food processing, can solve the problems of burnt yellow, easy to over fry, uneven color of frying, etc., and achieve the effect of fast coloring, short frying time, and uniform coloring and coloring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

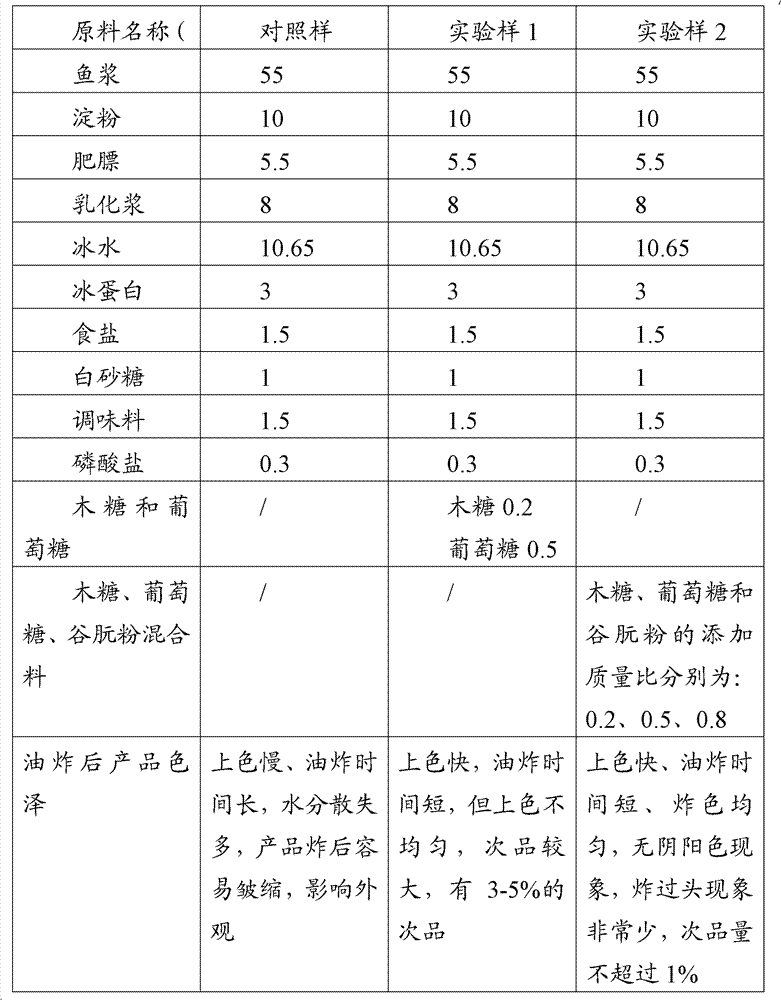

[0023] When making fish cakes or fish tofu, add xylose with a mass ratio of 0.2, glucose with a mass ratio of 0.5 and gluten with a mass ratio of 0.8. The fried fish cakes or fish tofu will be colored quickly and evenly. The phenomenon of over-frying is rare, and the quantity of defective products is small.

[0024] As shown in Table 1, it is the fish cake or fish bean curd without adding xylose, glucose and gluten provided by the present invention and the fish cake or fish bean curd fried with xylose, glucose and gluten.

[0025]

[0026] Table I

[0027] It should be noted that the mass ratio of xylose, glucose and gluten in Table 1 is relative to the mass ratio of the whole fish cake or fish tofu. However, the present invention does not limit the composition and addition ratio of other raw materials of the fried product, and those skilled in the art can add other appropriate raw materials to the fried product according to actual needs.

Embodiment 2

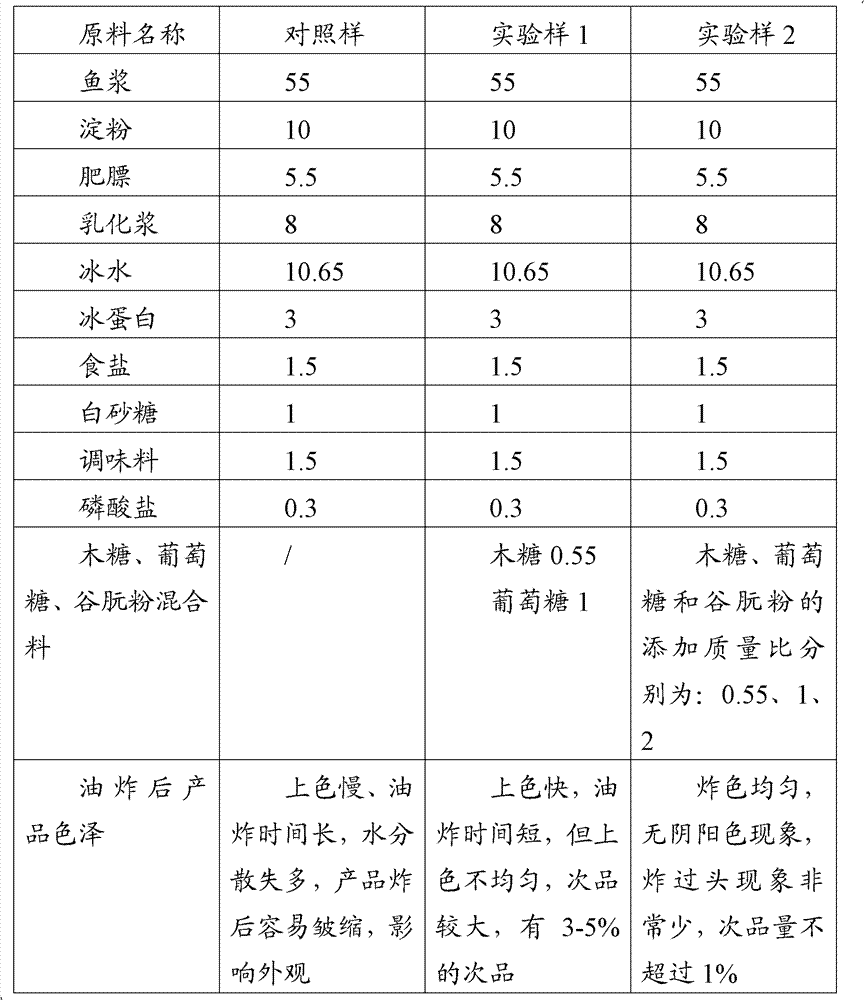

[0029] When making fish cakes or fish tofu, add xylose with a mass ratio of 0.55, glucose with a mass ratio of 1, and gluten with a mass ratio of 2. The fried fish cakes or fish tofu will be colored quickly and evenly. The phenomenon of over-frying is rare, and the quantity of defective products is small.

[0030] As shown in Table 2, it is the fish cake or fish bean curd without adding xylose, glucose and gluten provided by the present invention and the fish cake or fish bean curd fried with xylose, glucose and gluten.

[0031]

[0032] It should be noted that the mass ratio of xylose, glucose and gluten in Table 2 is relative to the mass ratio of the whole fish cake or fish tofu. However, the present invention does not limit the composition and addition ratio of other raw materials of the fried product, and those skilled in the art can add other appropriate raw materials to the fried product according to actual needs.

Embodiment 3

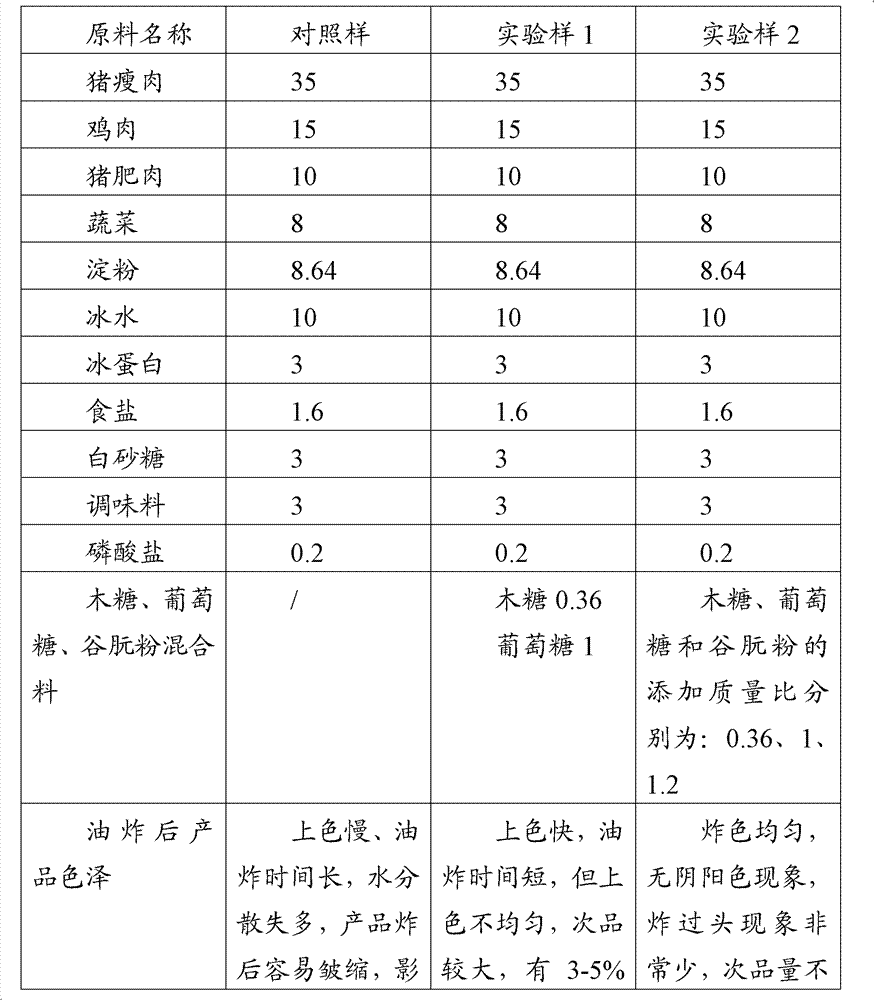

[0034] Add xylose with a mass ratio of 0.36, glucose with a mass ratio of 1, and gluten powder with a mass ratio of 1.2 when making fried meat patties. The fried meat patties will be colored quickly and evenly, and the phenomenon of over-fried Rarely, the amount of defective products is small.

[0035] As shown in Table 3, it is the result comparison of frying without adding xylose, glucose and gluten and adding xylose, glucose and gluten fried meat cake provided by the present invention.

[0036]

[0037]

[0038] Table three

[0039] It should be noted that the mass ratio of xylose, glucose and gluten in Table 3 is relative to the mass ratio of the whole fried patty. However, the present invention does not limit the composition and addition ratio of other raw materials of the fried product, and those skilled in the art can add other appropriate raw materials to the fried product according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com