Two kinds of methylprednisolone sodium succinate freeze-dried powder injection and preparation method thereof

A technology of methylprednisolone sodium succinate and freeze-dried powder injection, which is applied in the field of methylprednisolone sodium succinate composition and can solve the problems of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

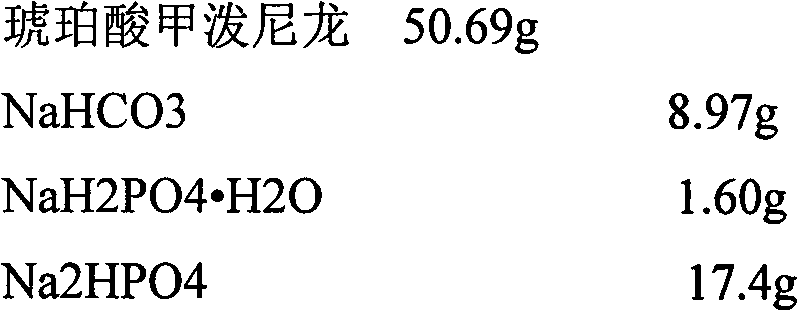

Embodiment 1-1

[0019]

[0020]

[0021] The preparation method is as follows:

[0022] 1. Weigh the prescription amount of NaHCO 3 , add 100ml of water for injection to dissolve, set aside.

[0023] 2. Weigh the prescription amount NaH 2 PO 4 ·H 2 O, add 100ml water for injection to dissolve, set aside.

[0024] 3. Weigh the prescription amount Na 2 HPO 4 , add 100ml of water for injection to dissolve, set aside.

[0025] 4. Weigh the main drug of the prescribed amount, add 500ml water for injection to stir into a suspension, and slowly add NaHCO under constant stirring 3 solution, heated to 70-80°C in a water bath and stirred, adding NaH 2 PO 4 ·H 2 O solution, then add Na 2 HPO 4 solution, add water for injection to 1000ml, keep warm in a water bath until the solution is clear, and circulate and filter the whole amount.

[0026] 5. Filter the medicinal solution with a 0.45 μm microporous membrane, and finally fine filter with a 0.22 μm microporous membrane.

[0027] 6. ...

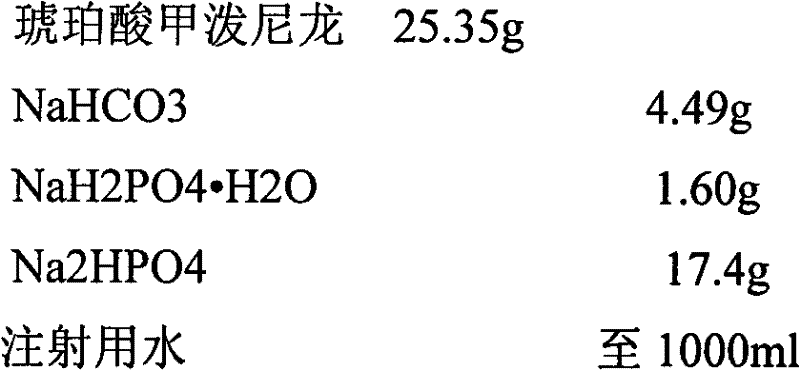

Embodiment 1-2

[0034]

[0035] The preparation method is as follows:

[0036] 1. Weigh the prescription amount of NaHCO 3 , add 100ml of water for injection to dissolve, set aside.

[0037] 2. Weigh the prescription amount NaH 2 PO 4 ·H 2 O, add 100ml water for injection to dissolve, set aside.

[0038] 3. Weigh the prescription amount Na 2 HPO 4 , add 100ml of water for injection to dissolve, set aside.

[0039]4. Weigh the main drug of the prescribed amount, add 500ml water for injection to stir into a suspension, and slowly add NaHCO under constant stirring 3 solution, heated to 70-80°C in a water bath and stirred, adding NaH 2 PO 4 ·H 2 O solution, then add Na 2 HPO 4 solution, add water for injection to 1000ml, keep warm in a water bath until the solution is clear, and circulate and filter the whole amount.

[0040] 5. Filter the medicinal solution with a 0.45 μm microporous membrane, and finally fine filter with a 0.22 μm microporous membrane.

[0041] 6. After the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com