Method for improving texture, color and luster of vacuum freeze-dried recombinant apple crisp chips

A technology of vacuum freeze-drying and apple chips, which is applied in the direction of food freezing, food drying, and bacteria used in food preparation. Stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

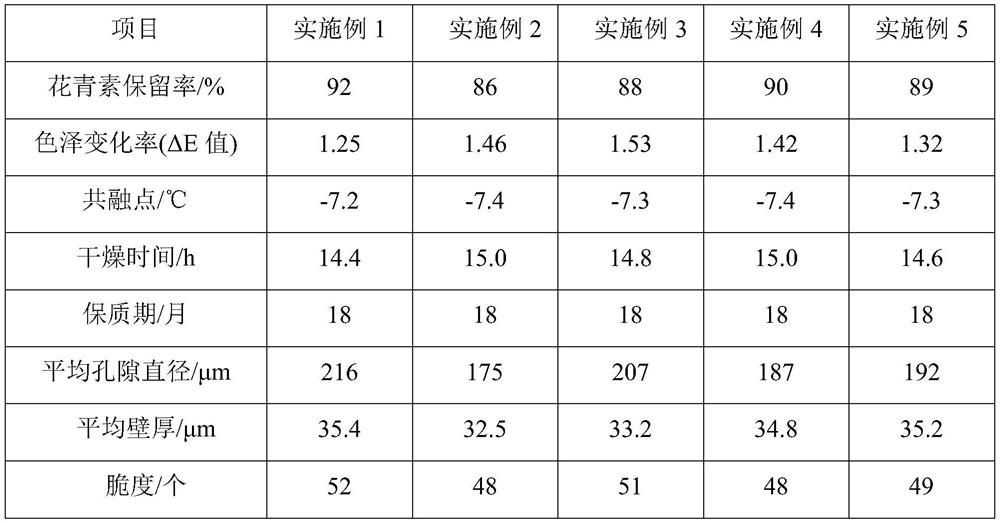

Embodiment 1

[0038] The method for improving the texture and color of vacuum freeze-drying reorganized apple crisp chips comprises the following steps:

[0039] Pretreatment: select red-fleshed apples with uniform maturity and no pests and diseases, clean the apples, peel and core them, and cut them in half;

[0040] Crushing: crushing the apples in a low-temperature nitrogen-filled crusher;

[0041] Beating: Put the apples in a beater and beat them to get apple pulp;

[0042] Blending: Add low-ester pectin to apple pulp at 50g / kg, calcium chloride at 1.5mg / g, ethyl p-hydroxybenzoate at 0.25g / kg, dry apple pomace powder with a mass fraction of 3%, and mix well After homogenization, a mixed solution is obtained; the addition amount is based on the quality of apple pulp;

[0043] Adjust pH: add citric acid to adjust pH to 3.5;

[0044] Sterilization: sterilize the apple pulp at 121°C for 15 minutes, and pour it into the fermenter after cooling;

[0045] Fermentation: 15g / kg of starter wa...

Embodiment 2

[0052] The method for improving the texture and color of vacuum freeze-drying reorganized apple crisp chips comprises the following steps:

[0053] Pretreatment: select red-fleshed apples with uniform maturity and no pests and diseases, clean the apples, peel and core them, and cut them in half;

[0054] Crushing: crushing the apples in a low-temperature nitrogen-filled crusher;

[0055] Beating: Put the apples in a beater and beat them to get apple pulp;

[0056] Blending: Add low-ester pectin to apple pulp at 10g / kg, calcium chloride at 1mg / g, sodium ethyl hydroxybenzoate at 0.012g / kg, dry apple pomace powder with a mass fraction of 2%, and mix well Homogenize to obtain a mixed solution; the amount of addition is based on the quality of the apple pulp;

[0057] Adjust pH: add malic acid to adjust pH to 3.0;

[0058] Sterilization: sterilize the apple pulp at 121°C for 15 minutes, and pour it into the fermenter after cooling;

[0059] Fermentation: 10g / kg of starter was a...

Embodiment 3

[0066] The method for improving the texture and color of vacuum freeze-drying reorganized apple crisp chips comprises the following steps:

[0067] Pretreatment: select red-fleshed apples with uniform maturity and no pests and diseases, clean the apples, peel and core them, and cut them in half;

[0068] Crushing: crushing the apples in a low-temperature nitrogen-filled crusher;

[0069] Beating: Put the apples in a beater and beat them to get apple pulp;

[0070] Blending: Add low-ester pectin to apple pulp at 25g / kg, calcium chloride at 2mg / g, propyl p-hydroxybenzoate at 0.5g / kg, and dry apple pomace powder with a mass fraction of 5%, and mix well Homogenize to obtain a mixed solution; the amount of addition is based on the quality of the apple pulp;

[0071] Adjust pH: add lactic acid to adjust pH to 3.8;

[0072] Sterilization: sterilize the apple pulp at 121°C for 15 minutes, and pour it into the fermenter after cooling;

[0073] Fermentation: 20g / kg of starter was ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com