A kind of multi-energy field casting and rolling preparation method of magnesium alloy strip

A magnesium alloy sheet, multi-energy field technology, applied in the preparation of magnesium alloy sheets and strips, the preparation of ultrasonic casting and rolling, the electromagnetic field of magnesium alloy sheets and strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

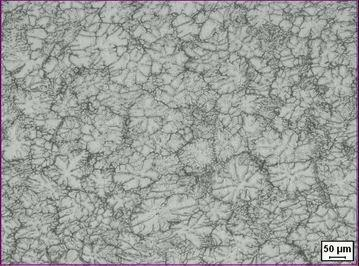

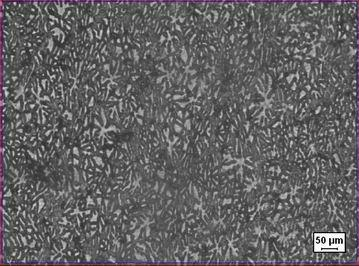

[0034] According to the composition ratio of AZ31B alloy, take 90Kg of magnesium ingot (industrial pure magnesium), 2750g of industrial pure aluminum, and 910g of pure zinc, put them into a melting furnace for melting at 706°C, and add 1.0% of covering agent and a small amount of common Protected by argon to prevent burning in contact with air, the mass percentage of the covering agent is: 55% magnesium chloride, 15% potassium chloride, 18% sodium chloride, and 12% calcium chloride. After the material is melted, add 0.6% scouring agent on the surface of the melt to remove slag and degas by stirring. The mass percentage of scouring agent components is: 55% magnesium chloride, 15% potassium chloride, 20% sodium chloride, Calcium chloride 5%, calcium fluoride 5%. While the magnesium alloy is being refined, heat the front box and the flow channel to 600°C, and keep it warm for 20 minutes after the magnesium alloy smelting is completed, so that the temperature of each part of the m...

Embodiment 2

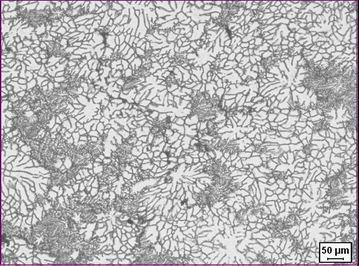

[0036]According to the composition ratio of the AZ31B alloy, take 90Kg of magnesium ingot (industrial pure magnesium), 2800g of industrial pure aluminum, and 920g of pure zinc, put them into a melting furnace for melting at 710°C, and add 0.8% of covering agent and a small amount of common Protected by argon to prevent burning in contact with air, the mass percentage of the covering agent is: 60% magnesium chloride, 18% potassium chloride, 15% sodium chloride, and 7% calcium chloride. After the material is melted, add 0.5% scouring agent on the surface of the melt to remove slag and degas by stirring. The mass percentage of scouring agent components is: magnesium chloride 58%, potassium chloride 15%, sodium chloride 17%, Calcium chloride 5%, calcium fluoride 5%. While the magnesium alloy is smelting, heat the front box and the flow channel to 550°C, and keep it warm for 15 minutes after the magnesium alloy smelting is completed, so that the temperature of each part of the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com