Manufacturing method of high temperature and high pressure steel pipe

A high temperature and high pressure, manufacturing method technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve problems such as cracks, and achieve the effect of reducing high temperature residence time and eliminating the possibility of welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

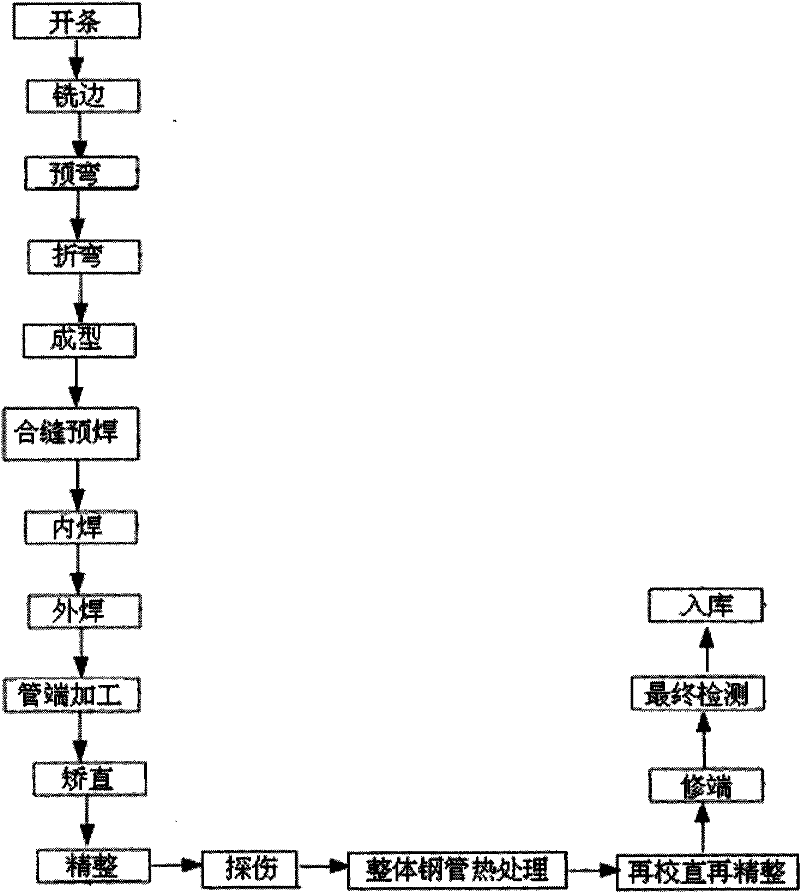

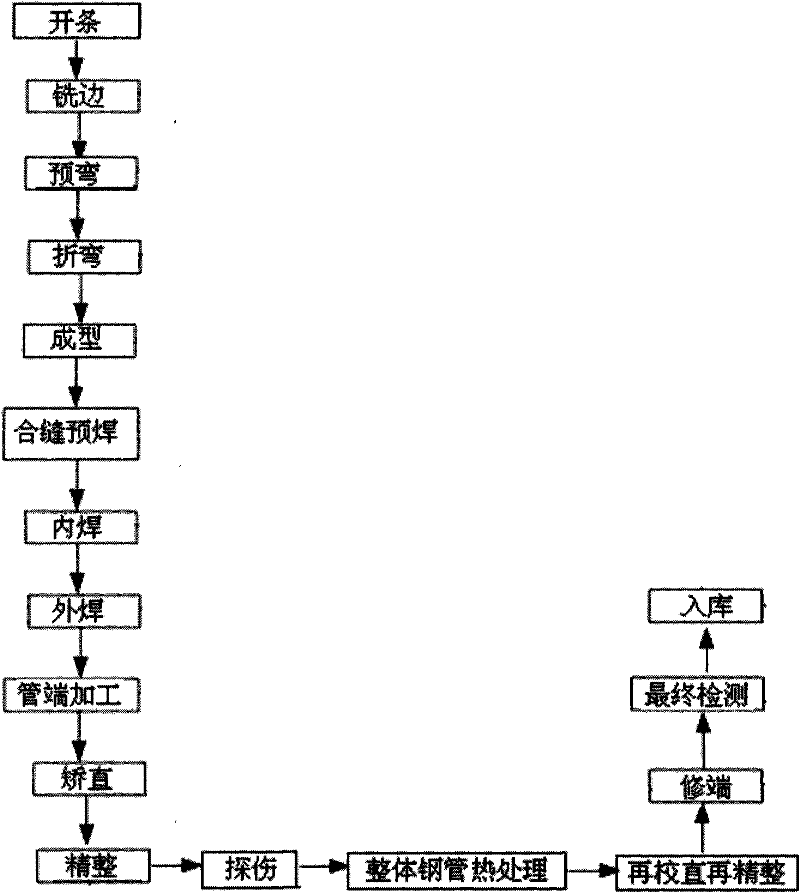

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0028] The method for manufacturing high-temperature and high-pressure steel pipes of the present invention is used for manufacturing high-temperature and high-pressure steel pipes made of ASTMA387.CL22.2. like figure 1 As shown, the manufacturing method of high temperature and high pressure steel pipe of the present invention comprises the following steps:

[0029] Step 1: Slitting, vertically cutting the steel plate;

[0030] Step 2: Edge milling, through a milling process on both sides of the steel plate;

[0031] Step 3: Pre-bending. Pre-bending is mainly to eliminate the straight edge of the plate end and bend the side of the plate into a circular arc.

[0032] Step 4: Bending, the steel plate is preliminarily folded into a cylindrical shape; focus on controlling the bending roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com