Thermal treatment method for improving mechanical performances of normalized steel plate

A heat treatment method and normalizing treatment technology, which is applied in the field of medium and heavy plate steel plate manufacturing, can solve the problems of poor welding adaptability, decreased mechanical performance strength, slow cooling speed, etc., to achieve increased strength, increased tensile strength, and uniformity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

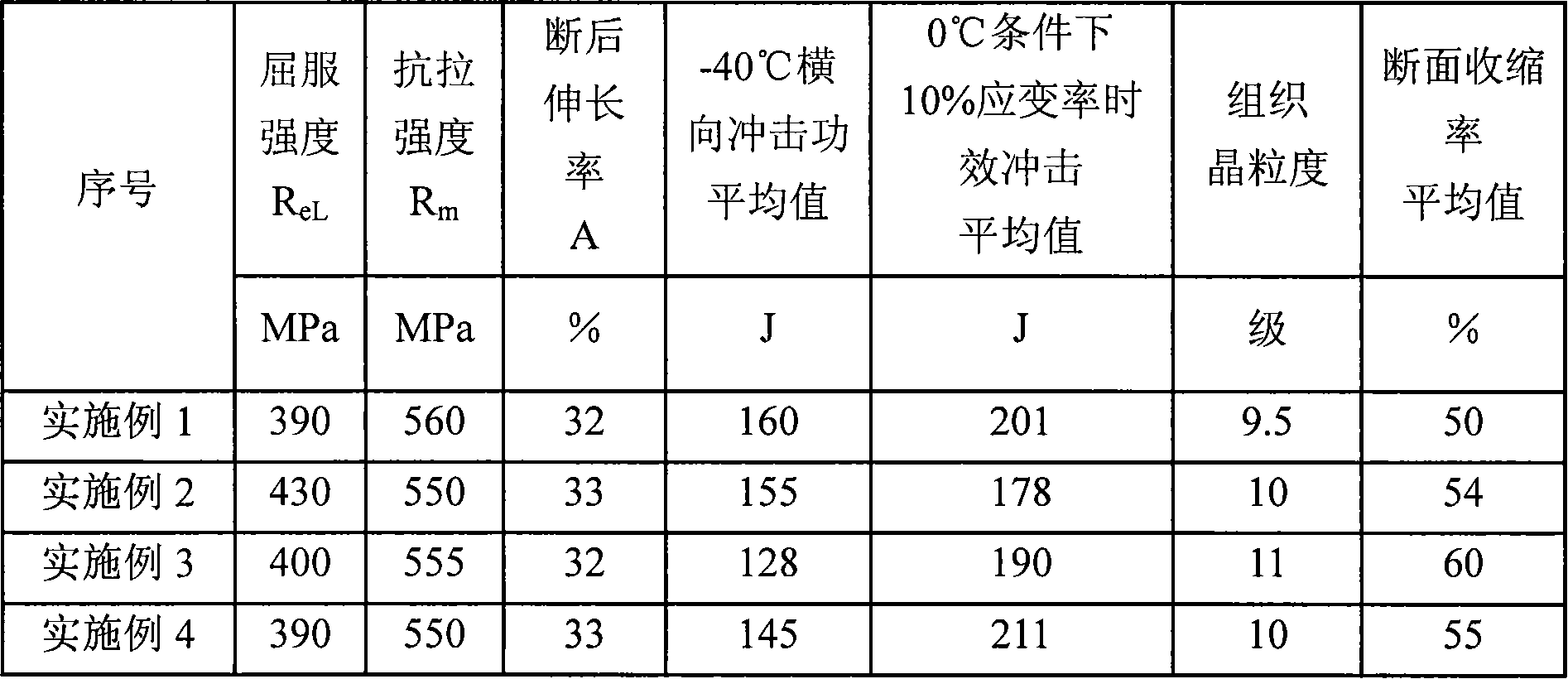

Embodiment 1

[0016] The heat treatment temperature of the rolled steel plate is 870°C, the heat preservation time is 40 minutes, the water ratio is 1, the roll speed is set at 40m / min, and the measured surface temperature of the steel plate after treatment is 600°C. The comprehensive mechanical properties of the steel plate are shown in Table 1.

Embodiment 2

[0018] The heat treatment temperature of the rolled steel plate is 880°C, the heat preservation time is 30 minutes, the water ratio is 1.01, the roll speed is set at 35m / min, and the measured surface temperature of the steel plate after treatment is 610°C. The comprehensive mechanical properties of the steel plate are shown in Table 1.

Embodiment 3

[0020] The heat treatment temperature of the rolled steel plate is 920°C, the temperature is kept for 5 minutes, the water ratio is 1.71, the roll speed is set at 12m / min, and the measured surface temperature of the steel plate after treatment is 780°C. The comprehensive mechanical properties of the steel plate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com