Roll transport vehicle

A roller body and vehicle-carrying technology, which is applied in the directions of transportation and packaging, winding strips, thin material handling, etc., can solve the problems of slow production time and complex structure of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

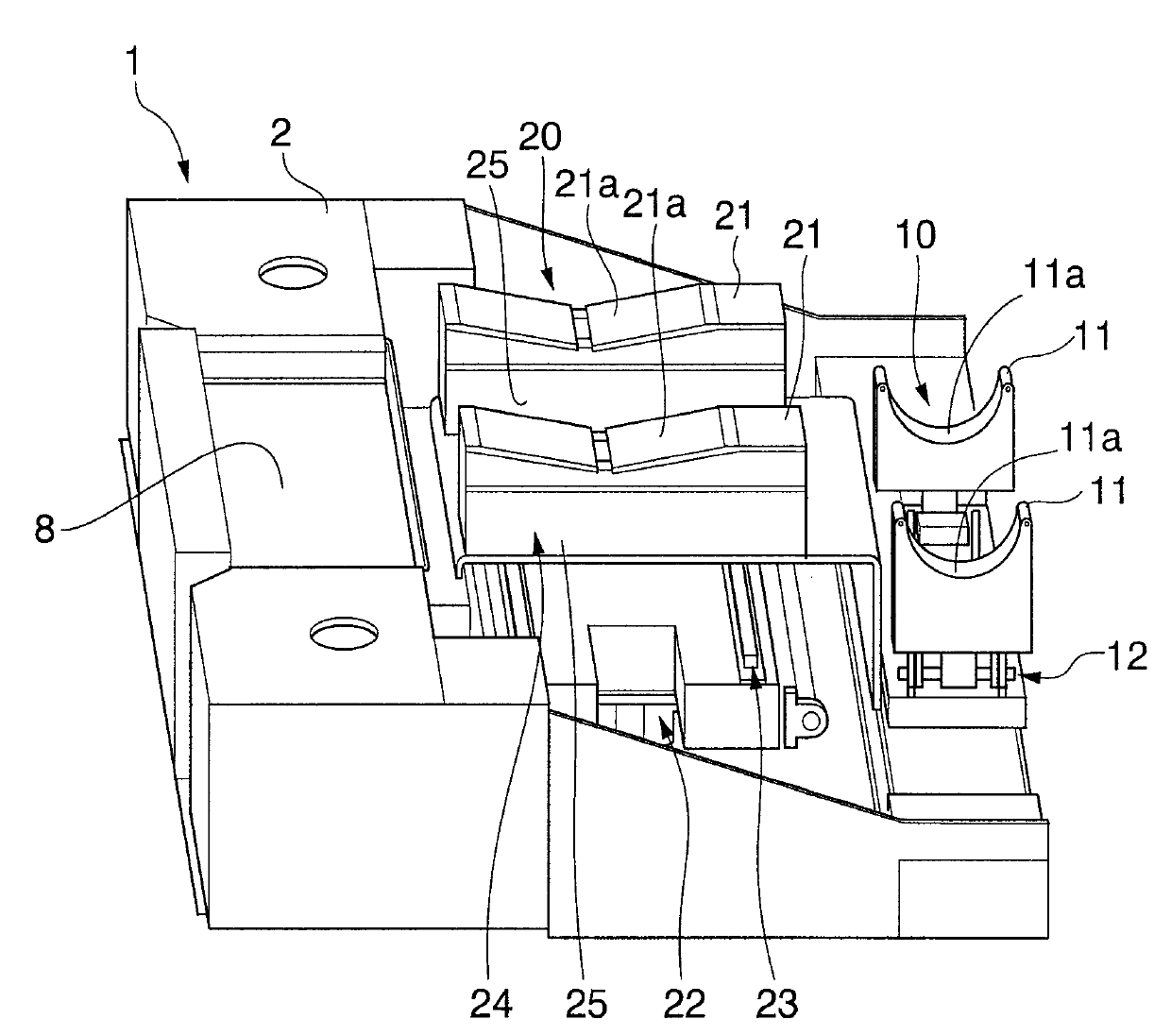

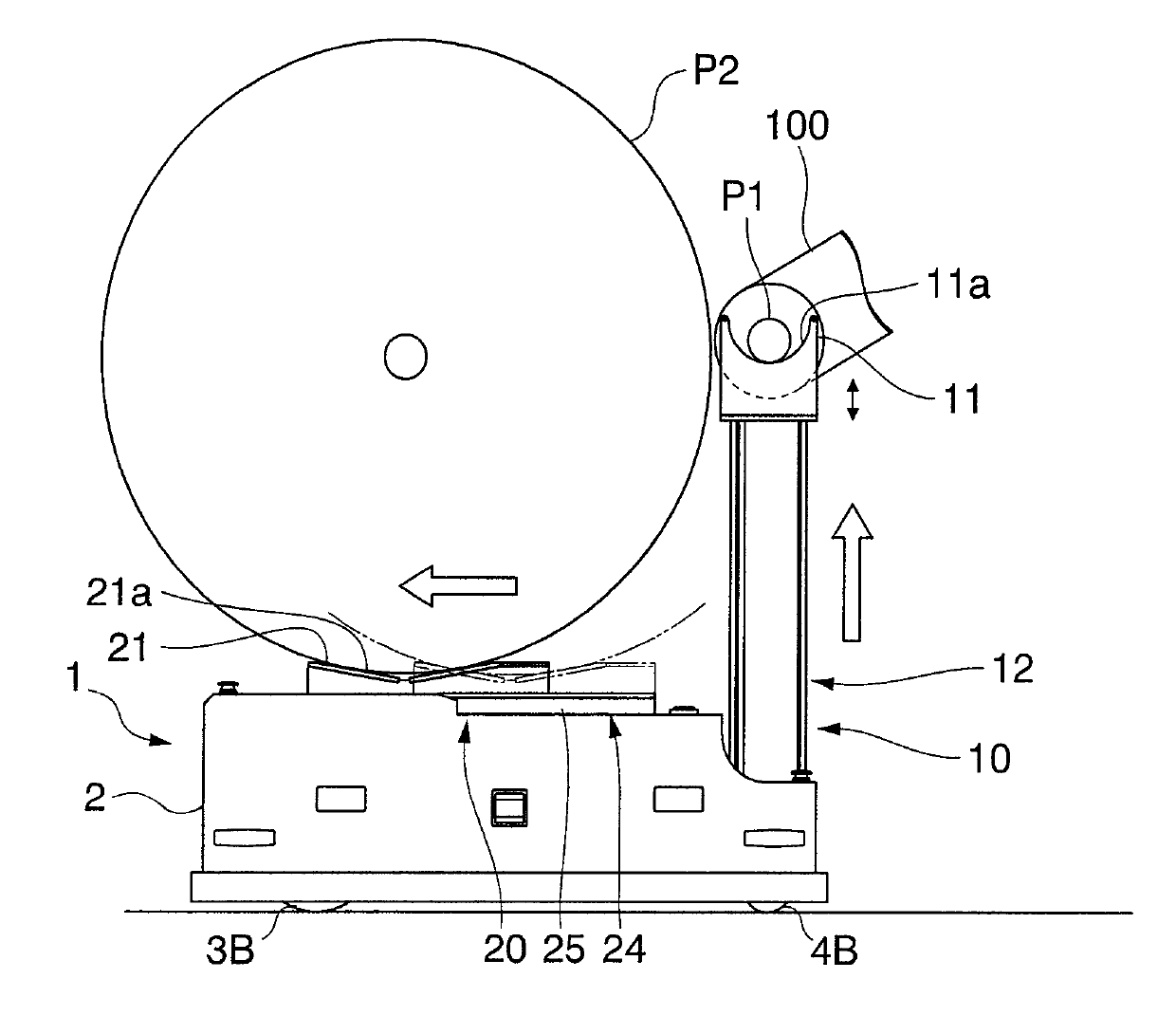

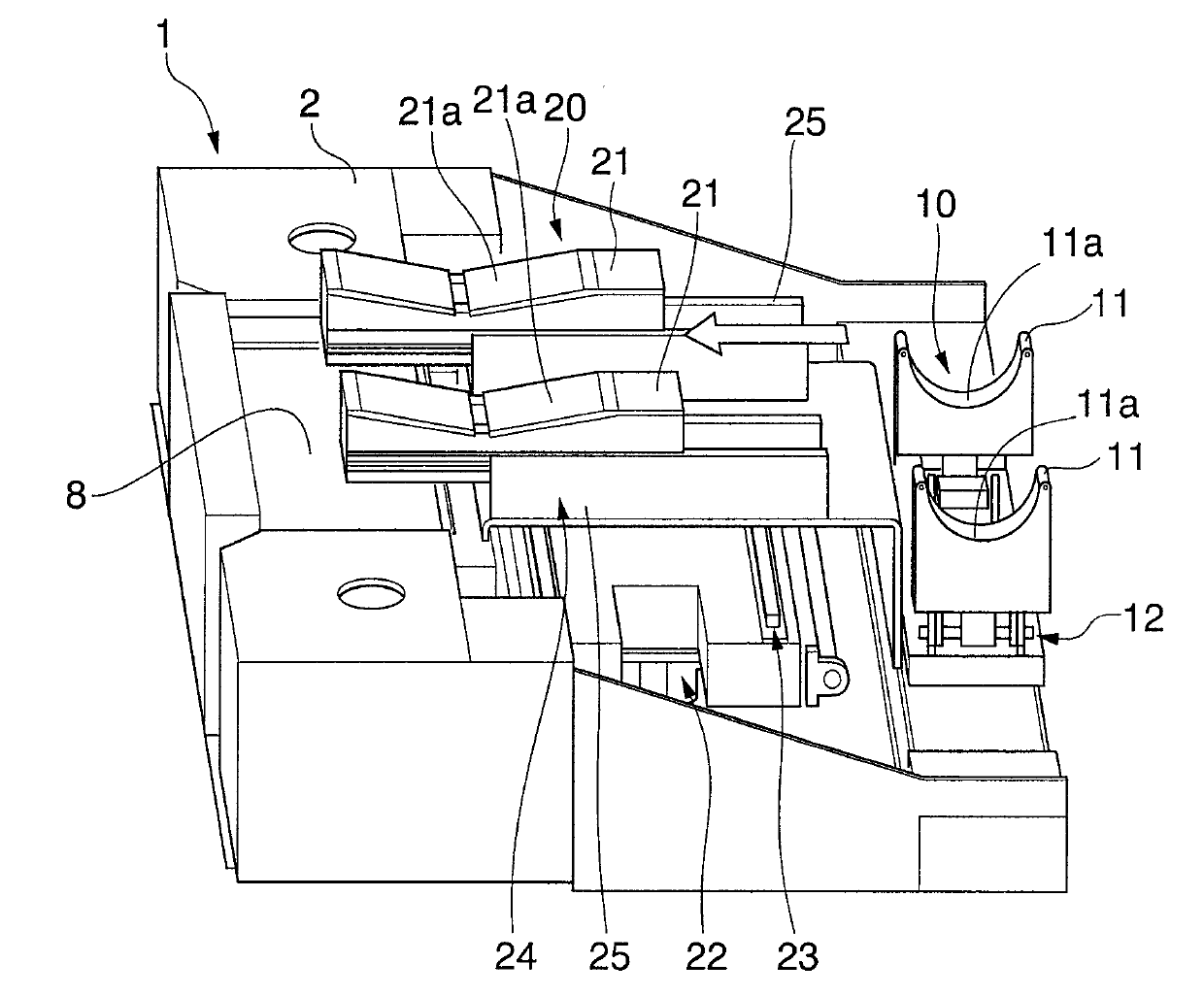

[0030] Hereinafter, a roller body transport vehicle according to an embodiment of the present invention will be described with reference to the drawings.

[0031] Figure 1A as well as Figure 1B It is a perspective view of the roller body conveyance vehicle 1 which concerns on embodiment of this invention. Figure 2A It is a top view of the roller body conveyance vehicle 1 which concerns on embodiment of this invention. Figure 2B It is a left side view of the roller body conveyance vehicle 1 which concerns on embodiment of this invention. image 3 It is a front view of the roller body conveyance vehicle 1 which concerns on embodiment of this invention.

[0032] The roll conveying vehicle 1 of the present embodiment is an AGV (Automated Guided Vehicle), and receives the roll paper directly from a storage stand for the roll paper (roll body) in a newspaper printing factory using a transfer device or directly from an output machine. On the other hand, paper feeding to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com