A single-rod square steel pipe support with casing and its construction method

A technology of square steel pipe and casing, which is applied in the field of single-rod square steel pipe support with casing and its structure, can solve the problems of early fracture deformation, low compressive stiffness and low compressive buckling capacity, and improve the compressive buckling capacity force, improve lateral stiffness and shear capacity, and prevent collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings.

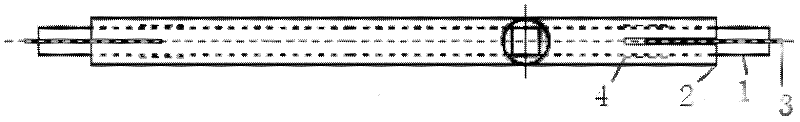

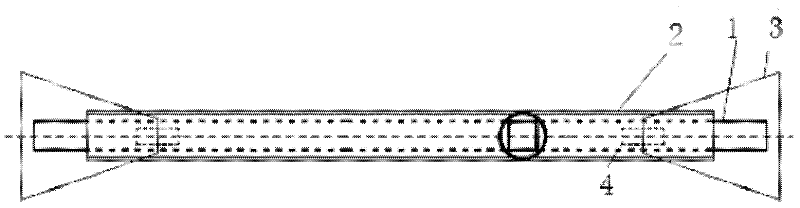

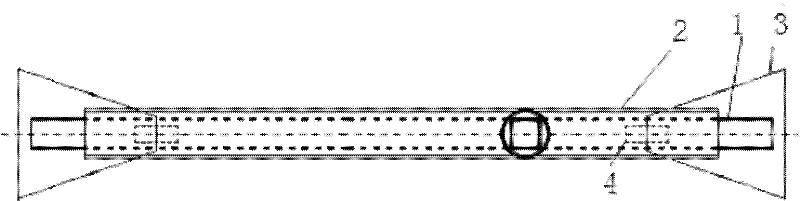

[0026] Such as figure 1 , figure 2 As shown, the single-rod square steel pipe support with casing includes a strip-shaped square steel pipe support 1 with horizontal and axial symmetry. Two ends of the square steel pipe support 1 are respectively embedded with a flared end plate 3, and the flared end plate 3 The large mouth end is outside the square steel pipe support 1, and the upper and lower surfaces of the small mouth end of the flared end plate 3 are respectively fixed with a reinforcing plate 4, and the outer surface of the square steel pipe support 1 is also covered with a sleeve 2 coaxial with it.

[0027] The manufacturing method of the single-rod square steel pipe support with casing, its steps are as follows:

[0028] Step 1: Determine the length and section size of the square steel pipe support 1 according to the design bearing capacity and deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com