Multi-storey building with prefabricated parts and its semi-prefabricated construction method

A multi-storey building, semi-prefabricated technology, applied to building components, residential buildings, building structures, etc., can solve the problems of high construction cost, long construction period, noise and dust on the construction site, etc., and achieve unified building quality standards and improved The efficiency of construction and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

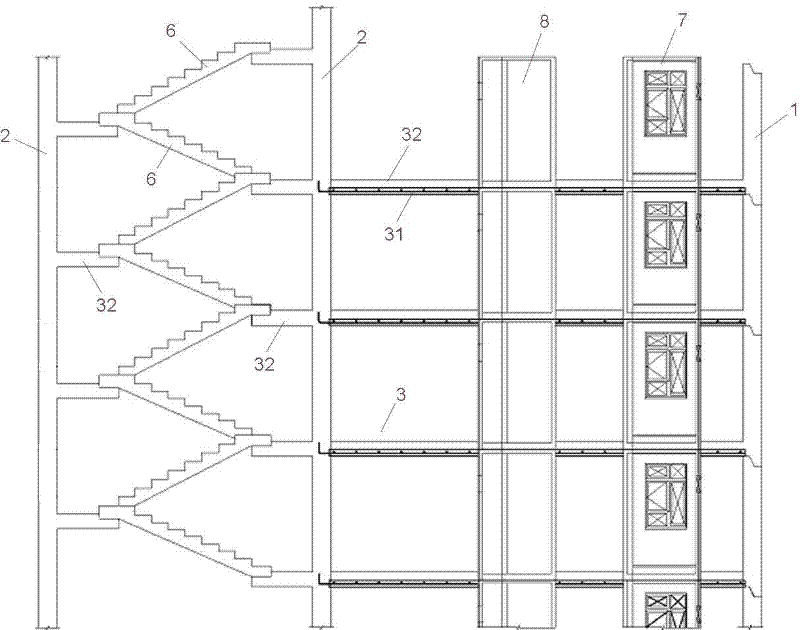

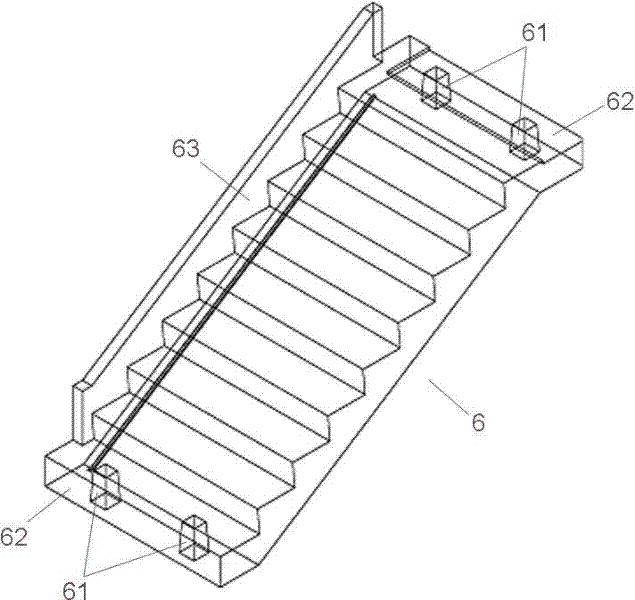

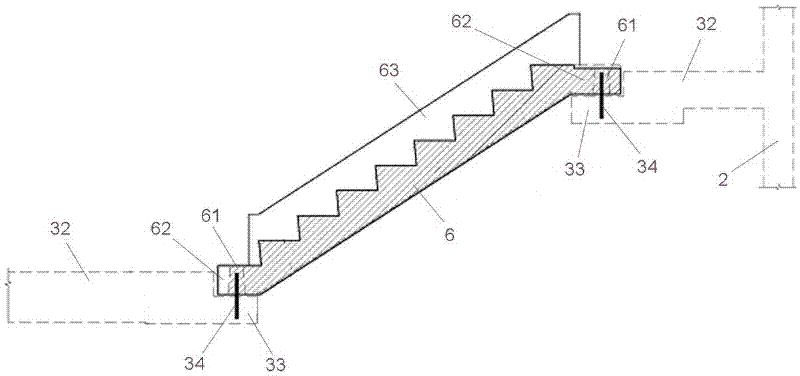

[0044] The multi-storey building with prefabricated parts of the present invention is mainly made up of body of wall, floor slab, stair, bearing column and beam etc., wherein, as figure 1 As shown, the wall is composed of a prefabricated exterior wall 1 and a cast-in-place wall 2 , the left and right ends of the prefabricated exterior wall 1 have preset exposed steel bars and are integrated with the cast-in-place wall 2 . The floor 3 is composed of a semi-prefabricated floor 31 and a cast-in-place floor 32 formed by laying steel bars on the semi-prefabricated floor 31 and pouring concrete. The special feature of the present invention is that the staircase adopts the prefabricated staircase 6, and also adopts the prefabricated bathroom 7 and the prefabricated kitchen 8, which can greatly reduce the workload of on-site construction and contribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com