Sand mixer for non-excavation directional drilling rig

A non-excavation, steering technology, applied in directional drilling, earthwork drilling, wellbore/well components, etc., can solve problems such as engineering failure, hole collapse, and inability to stir the sediment at the bottom of the hole, so as to ensure stability, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

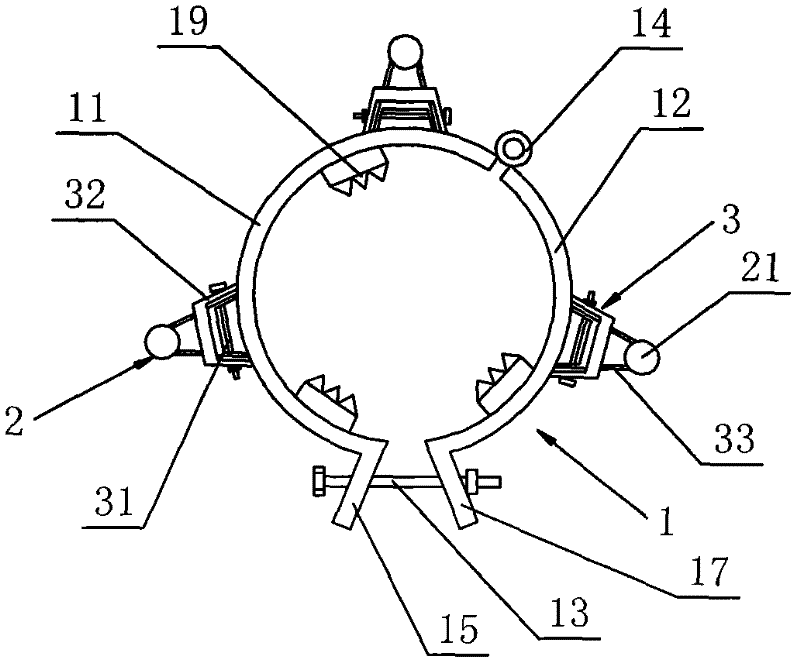

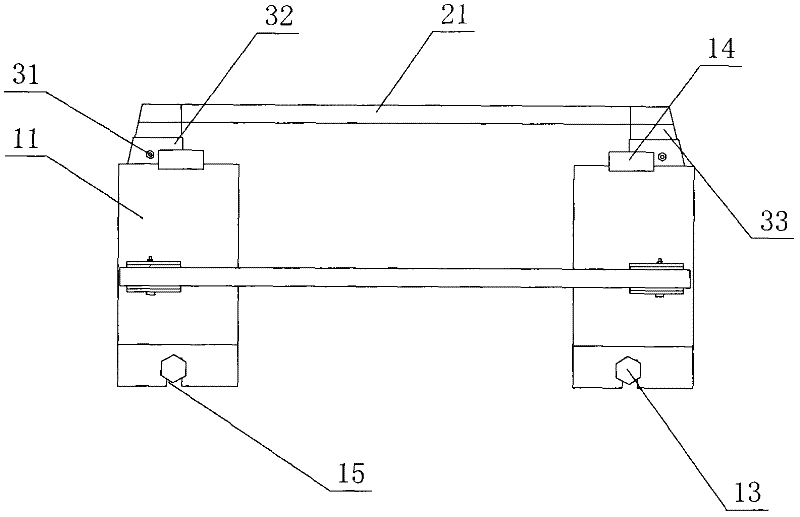

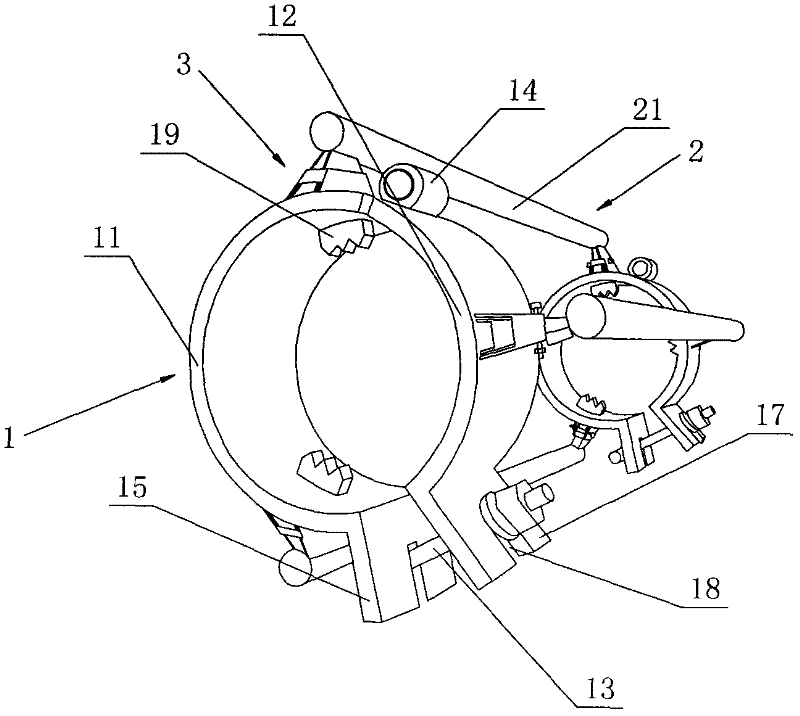

[0029] Such as figure 1 , figure 2 and image 3 As shown, a sand mixer for a non-excavation directional drilling rig includes two sets of locking devices 1 and three sets of stirring devices 2, the stirring devices 2 are connected to the outside of the locking device 1 through a connecting device 3, and in the lock When the tightening device 1 rotates, the stirring device 2 and the locking device 1 rotate synchronously.

[0030] The locking device 1 in this embodiment is a component that connects the mud mixer and the rotating rod as a whole during work. The locking device 1 includes a circular arc-shaped first buckle 11, a second buckle 12 and a locking ring. The connector, the locking connector in this embodiment adopts locking screw 13, wherein: the inner wall of the first buckle 11 is evenly provided with two clamping teeth 19, and the inner wall of the second buckle 12 is provided with a clamping tube Teeth 19, the clamping pipe teeth 19 can further lock the rotating ...

Embodiment 2

[0035] Such as Figure 4 As mentioned above, the difference between this embodiment and Embodiment 1 is that the locking device 1 includes a circular locking ring 101, latch teeth 102 and top bolts 103, and the ring wall of the circular locking ring 101 is provided with three The bolt hole 104 that 103 cooperates, the rear wall of bayonet 102 is provided with the bolt groove 105 that cooperates with top bolt 103, and the top end of top bolt 103 passes through bolt hole 104, and the top end of top bolt 103 is positioned at bolt groove 105.

[0036] In the silt mixer for the non-excavation directional drilling machine of the present invention, the shape of the stirring rod can be set as cylindrical or polygonal as required.

[0037] The sand stirrer for the non-excavation directional drilling rig of the present invention can adjust the number of cylindrical stirring rods 21 according to the situation of the soil layer during construction. When encountering a clay layer, 1-2 cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com