Preparation method of multiple sets of impellers for wind power generator

A technology for wind turbines and impellers, applied in wind turbine components, assembly of wind engines, wind engines, etc., can solve problems such as low utilization rate of wind energy, lack of attention to vertical axis wind turbines, etc., and achieve easy maintenance, Lower center of gravity, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

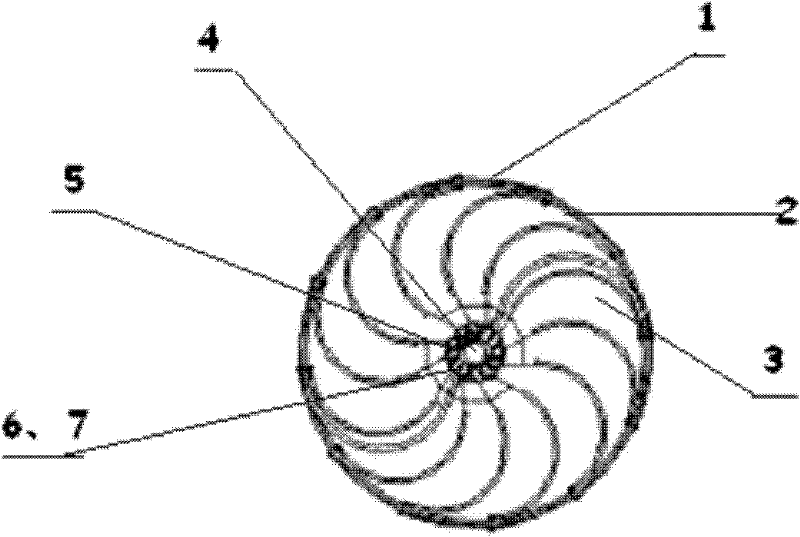

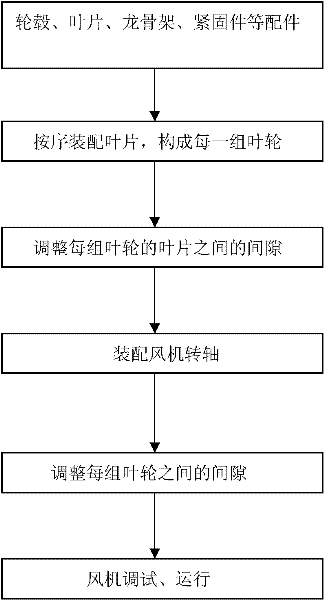

[0012] refer to figure 2 , the invention points out the process flow path for preparing multiple sets of fan impellers. Specifically, the helical blades 3 that assemble at least two hubs are prepared in order, at least two keel frames 5 are prepared, and at least two or more fasteners 7 are prepared; one end of the blade 3 is installed on the The blade positioning groove 6 of the hub 4 is locked with a fastener 7, and then the other end of the blade is connected with the keel frame 5 and locked with a fastener 6 to complete the assembly of one set of impellers, and then assemble the other in the same way. A group of impellers, after that, adjust the gap between each blade so that it is between 0.01 and 1.77 centimeters and make the spacing even; then each group of impellers is assembled on a shaft 4 concentrically and coaxially (hub The hole position is coaxial with the generator), at this time, the shape of the blades of each set of impellers assembled should be stacked rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com