A horizontal disc dryer

A disc dryer, horizontal technology, applied in the direction of non-progressive dryers, drying machines, drying solid materials, etc., can solve problems such as unsafe, high risk, and labor-intensive workers, and achieve good social and economic benefits Benefits, reduce labor intensity, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

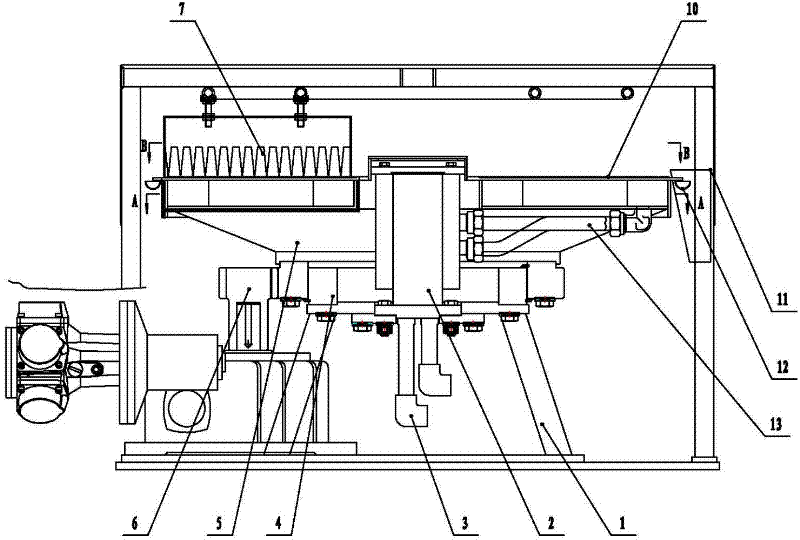

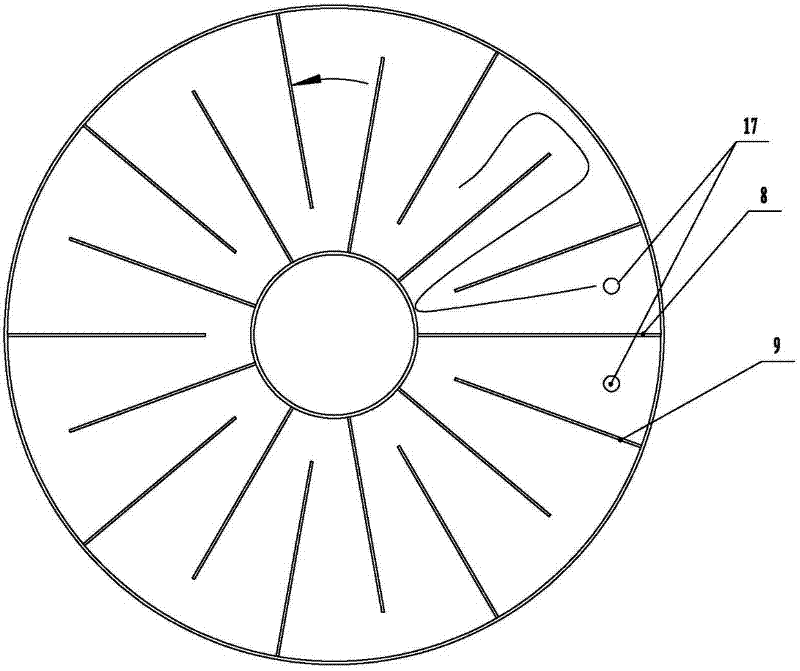

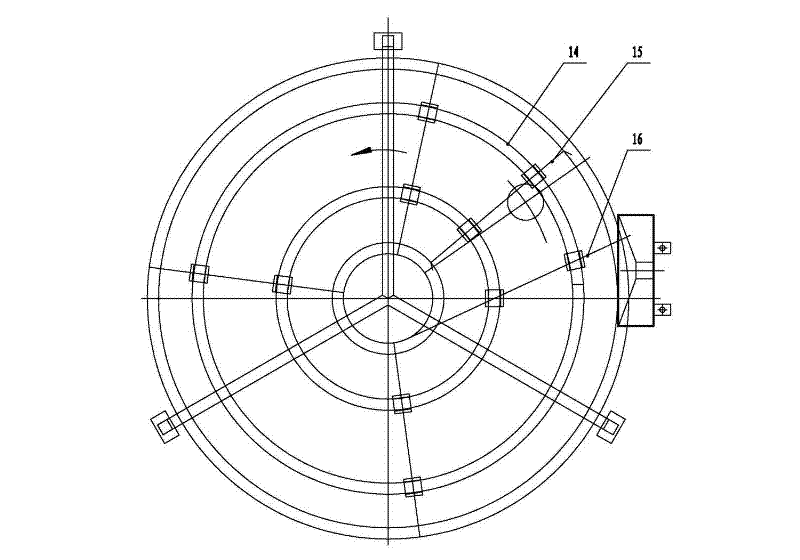

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention consists of a frame 1, a rotary joint 2, a slewing support 4, a heating plate body 5, a drive device 6, a material distribution device 15, a rake tooth device 7, a discharge device 16, a bridge device 14, a material receiving device 12 and The casing 11 is composed of; the heating plate body 5 is connected with the outer ring of the slewing support 4, the inner ring of the slewing support 4 is connected with the frame 1, and the heating plate body 5 and the outer ring of the slewing support 4 operate synchronously; The driving device 6 is connected with the slewing support 4, and drives the slewing support 4 to drive the heating plate body 5 to run horizontally and circularly; the central axis of the rotary joint 2 is fixed at the center of the frame 1, and the central axis is provided with two interfaces to communicate with the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com