System and method for measuring true density of powder samples under anhydrous and oxygen-free conditions

A water-free and oxygen-free measurement system technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of temperature influence, solvent, gas and other impurities pollution and deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

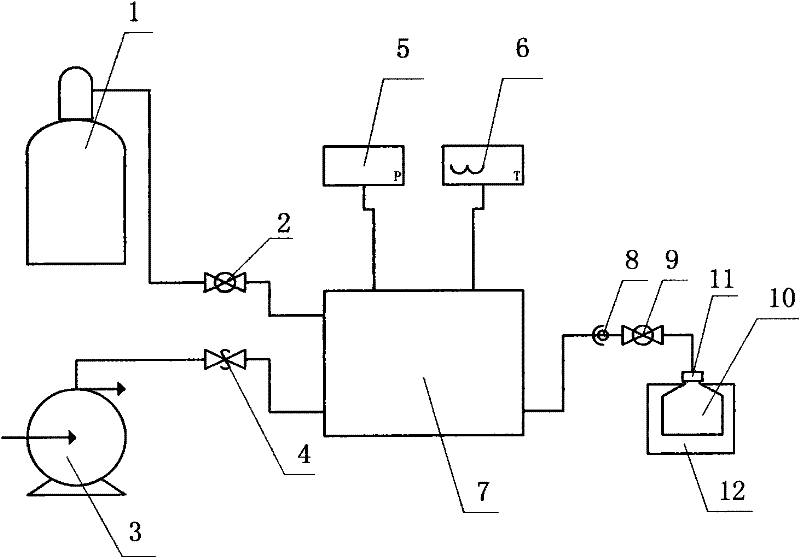

[0130] A system for measuring the true density of powder samples at room temperature under anhydrous and oxygen-free conditions, comprising an airtight container 7 and a gas cylinder 1 connected to the airtight container, a vacuum pump 3 , a pressure gauge 5 , a thermometer 6 and a sample bottle 10 .

[0131] Airtight container 7 can be stainless steel container or quartz, glass container, requires good airtightness and ability vacuum, is used for providing standard volume,

[0132]The gas cylinder 1 and the airtight container 7 are connected by a pipeline, and an on-off valve 2 is installed in the pipeline for controlling the feeding of gas into the airtight container.

[0133] The vacuum pump 3 and the airtight container 7 are connected by a pipeline, and a limiting valve 4 is installed in the pipeline to control the pressure drop rate of the airtight system.

[0134] The pressure gauge 5 and the thermometer 6 are directly connected to the airtight container 7 respectively, ...

Embodiment 2

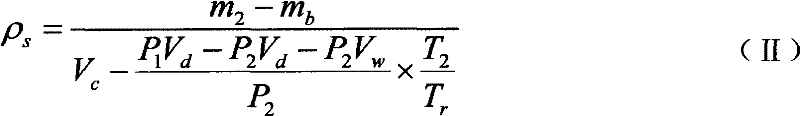

[0139] A system for determining the true density of powder samples under anhydrous and oxygen-free conditions at non-room temperature, comprising a closed container 7 and a gas cylinder 1 connected to the closed container, a vacuum pump 3, a pressure gauge 5, a thermometer 6, a sample bottle 10 and a temperature control Device 12.

[0140] Airtight container 7 can be stainless steel container or quartz, glass container, requires good airtightness and ability vacuum, is used for providing standard volume,

[0141] The gas cylinder 1 and the airtight container 7 are connected by a pipeline, and an on-off valve 2 is installed in the pipeline for controlling the feeding of gas into the airtight container.

[0142] The vacuum pump 3 and the airtight container 7 are connected by a pipeline, and a limiting valve 4 is installed in the pipeline to control the pressure drop rate of the airtight system.

[0143] The pressure gauge 5 and the thermometer 6 are directly connected to the ai...

Embodiment 3

[0150] A method for measuring the true density of Ziegler-Natta catalysts under anhydrous and oxygen-free conditions at room temperature, the method uses the measurement system described in Embodiment 1 of the present invention.

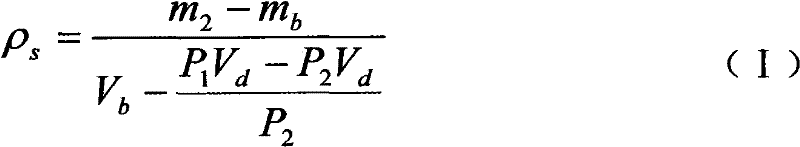

[0151] First weigh the quality m of the empty sample bottle, sealing plug, controllable valve switch and the pipeline between them b , put the sample bottle into the glove box and load Ziegler-Natta catalyst, plug the sealing plug and close the controllable valve switch, take it out from the glove box, weigh the sample bottle, sealing plug and controllable valve switch after loading the catalyst and The mass of the pipeline between them m 2 , connect the sample bottle to the closed system; confirm that the on-off valve 2 and the controllable valve switch 9 are in the closed state, open the vacuum pump 3 and the limit valve 4, until the pressure in the airtight container 7 is less than 50 μmHg, and keep it for 30 minutes; close the limit valve 4, open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com