Monitoring method and monitoring system of programmable logic controller (PLC)

A programming logic and monitoring system technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of long development and debugging cycle, many program versions, and non-standardization, etc., to achieve short development and debugging cycle, shorten debugging time, The effect of reducing the difficulty of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the drawings and embodiments.

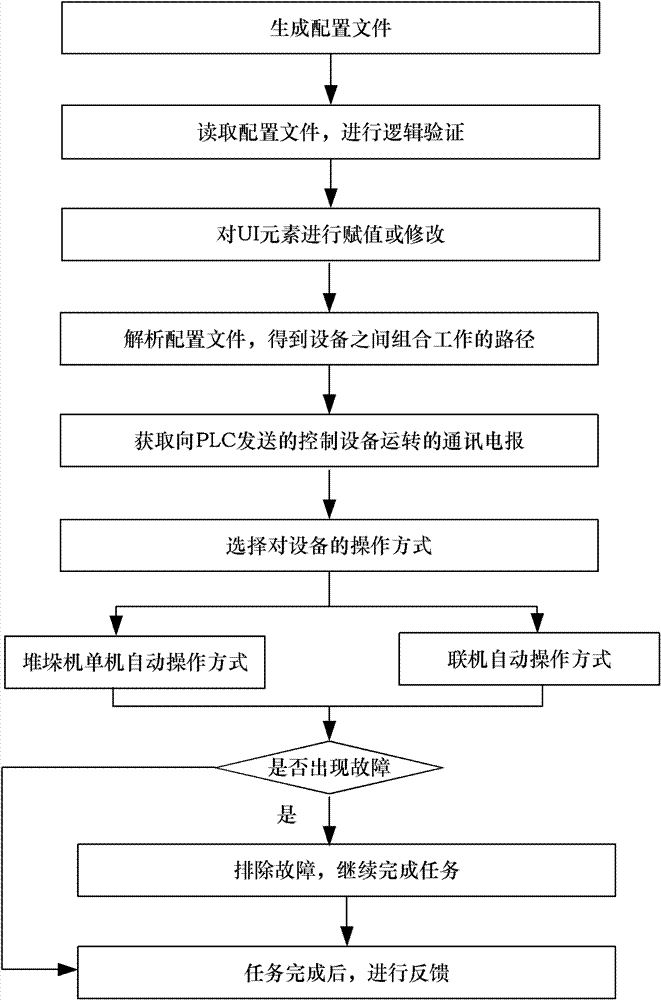

[0035] Such as figure 1 As shown, the PLC monitoring method of the present invention specifically includes the following content:

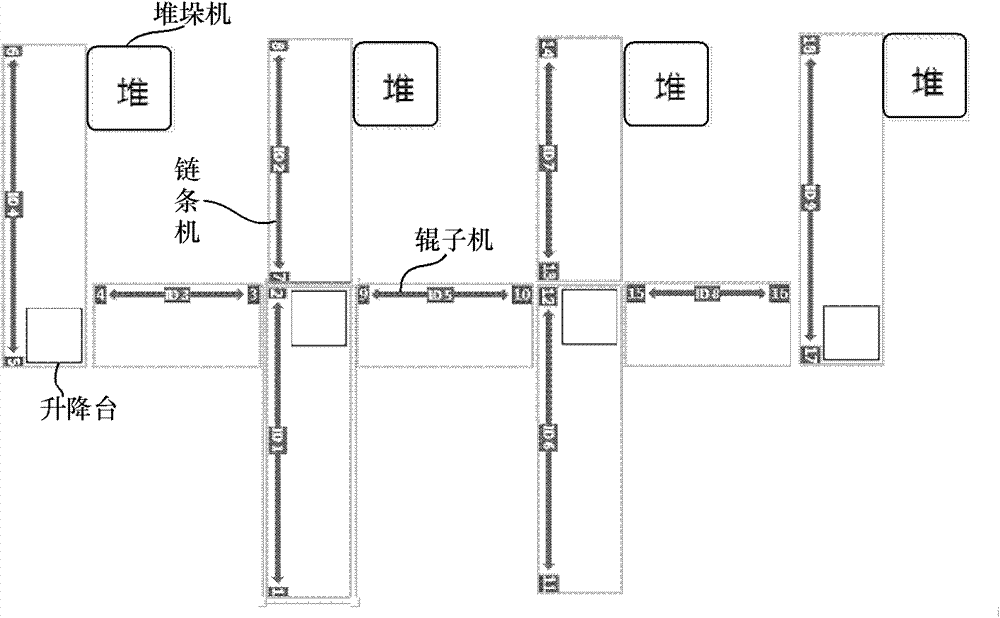

[0036] Step 1: Generate configuration files. The generation process of the configuration file in the present invention is: in the graphical interface, the user according to the number of the three-dimensional warehouse equipment and the logical relationship between the equipment, through the graphic drag and drop method, the graphics representing the three-dimensional warehouse equipment are combined and filled in Or select the attributes of each device to complete the generation of the configuration file. Such as figure 2 As shown, figure 2 Among them, the boxed pile graph represents the stacker, the double arrow represents the conveyor, the direction of the arrow represents the running direction of the conveyor, the horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com